4

L

O

P

C

F

F

O

R

E

M

O

T

E

L

O

C

A

L

BIFFI FAIL SAFE ELECTRIC ACTUATORS, MODEL EFS2000V4

InstructIon and operatIng Manual

3 STORAGE AND PRE-INSTALLATION

IMPORTANT

Omitting the following procedures will invalidate

the product warranty.

3.1 Checks to be carried out on receipt of the

actuator

• Check first of all if the information written

on the nameplate (models, nominal torque,

nominal voltage, degree of protection, etc.)

corresponds with the data of the product

which is expected.

• If the actuator arrives already assembled onto

the valve, the configuration of the mechanical

stops and of the electric end of travel has

already been made by the person who

assembled the actuator onto the valve.

• If the actuator arrives separately from the

valve, the configuration of the mechanical

stops and of the electric end of travel must be

checked and, if necessary, carried out while

assembling the actuator onto the valve.

• Check that the actuator has not been

damaged during transport. If necessary,

repair all damages to the paint-coat, etc.

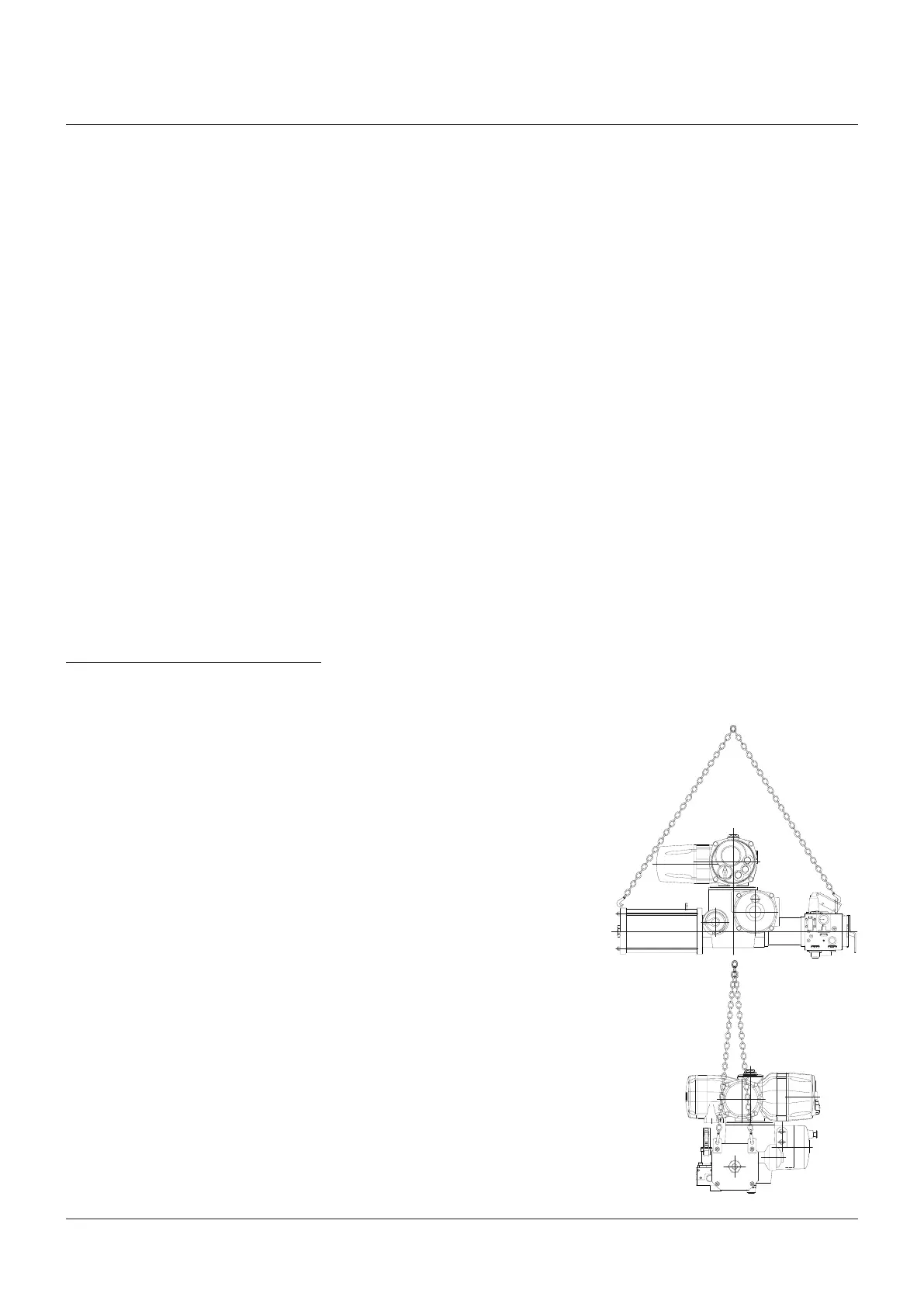

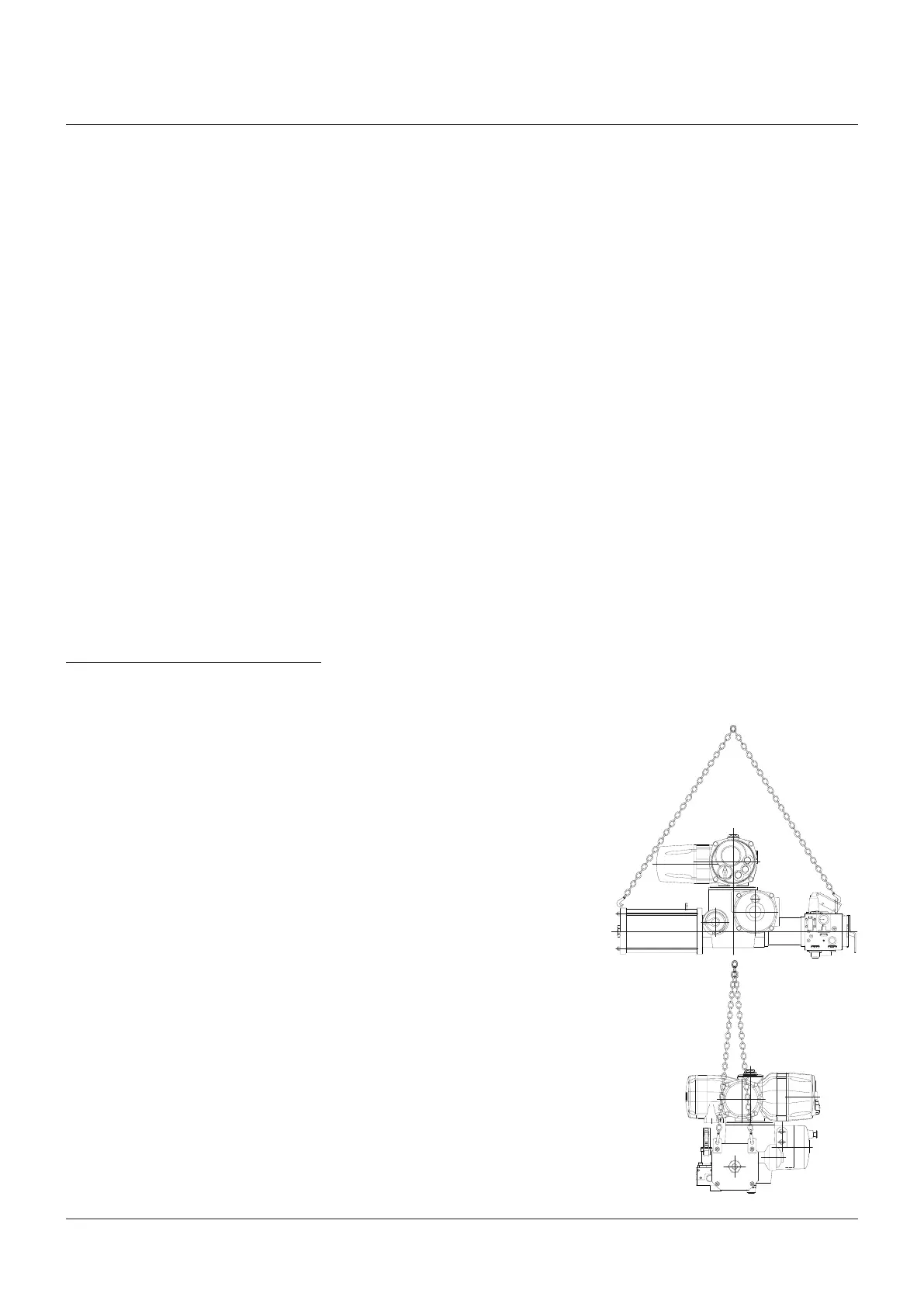

Actuator’s lifting points

• Check that the model, the serial number

of the actuator and the performance data

written on the data-plate correspond

with those described on the order

acknowledgement, test certificate and

delivery note.

• Check that the fitted accessories

correspond with those listed in the order

acknowledgement and the delivery note.

3.2 Actuator handling

IMPORTANT

The lifting and handling should be made by

qualified staff and in compliance with the laws

andprovisions in force.

WARNING!

The fastening points are appropriate for the

lifting of the actuator alone and not for the

valve+actuator assembly. Avoid that during the

handling, the actuator passes above the staff.

The actuator should be handled with appropriate

lifting means. The weight of the actuator is

reported on the delivery bill.

3.3 Storage procedure

The actuators leave the factory in an excellent

working condition and with an excellent

finish (these conditions are guaranteed by

an individual inspection certificate); in order

to maintain these characteristics until the

actuator is installed on the plant, it is necessary

to observe a few rules and take appropriate

measures during the storage period.

• Make sure that plugs are fitted in the air

connections and in the cable entries. The

plastic plugs which close the inlets do not

have a weatherproof function, but are only

a means of protection against the entry of

foreign matter during transport. If long-term

storage is necessary and especially if the

storage is outdoor, the plastic protection

plugs must be replaced by metal plugs,

which guarantee a complete weatherproof

protection.

Input shaft of the epicyclical gearing reduction

is connected the multi-turn actuator output

shaft; output shaft of the epicyclical gearing

reduction is connected to the pinion of rack-

pinion mechanism. The female wheel of the

epicyclical reduction is reversible: during

normal operation it is kept on position by

means of a electromagnetic clutch which hold

the worm shaft connected to the epicyclical

gearing.

The coil of the electromagnetic clutch is

normally fed by a direct current from separated

external power source, or derived from motor

power voltage, through a supply module.

When the ESD condition occurs, the supply to

the electromagnetic clutch is cut causing the

disconnection of system which hold the worm

shaft: in this conditions the epicyclical gearing

become reversible causing the movement of

the actuator on the fail condition by the effect

of the spring. To avoid dangerous shock to

the valve during the ESD action, an hydraulic

damper is mounted on the spring system, with

an adjustable flow control orifice to be set to

obtain the specified ESD times.

Position of the valve is continuously monitored

both in electric mode, both in fail-safe

condition, by means of a position sensor

directly connected the EFS2000v4 output drive.

Loading...

Loading...