58

BIFFI FAIL SAFE ELECTRIC ACTUATORS, MODEL EFS2000V4

InstructIon and operatIng Manual

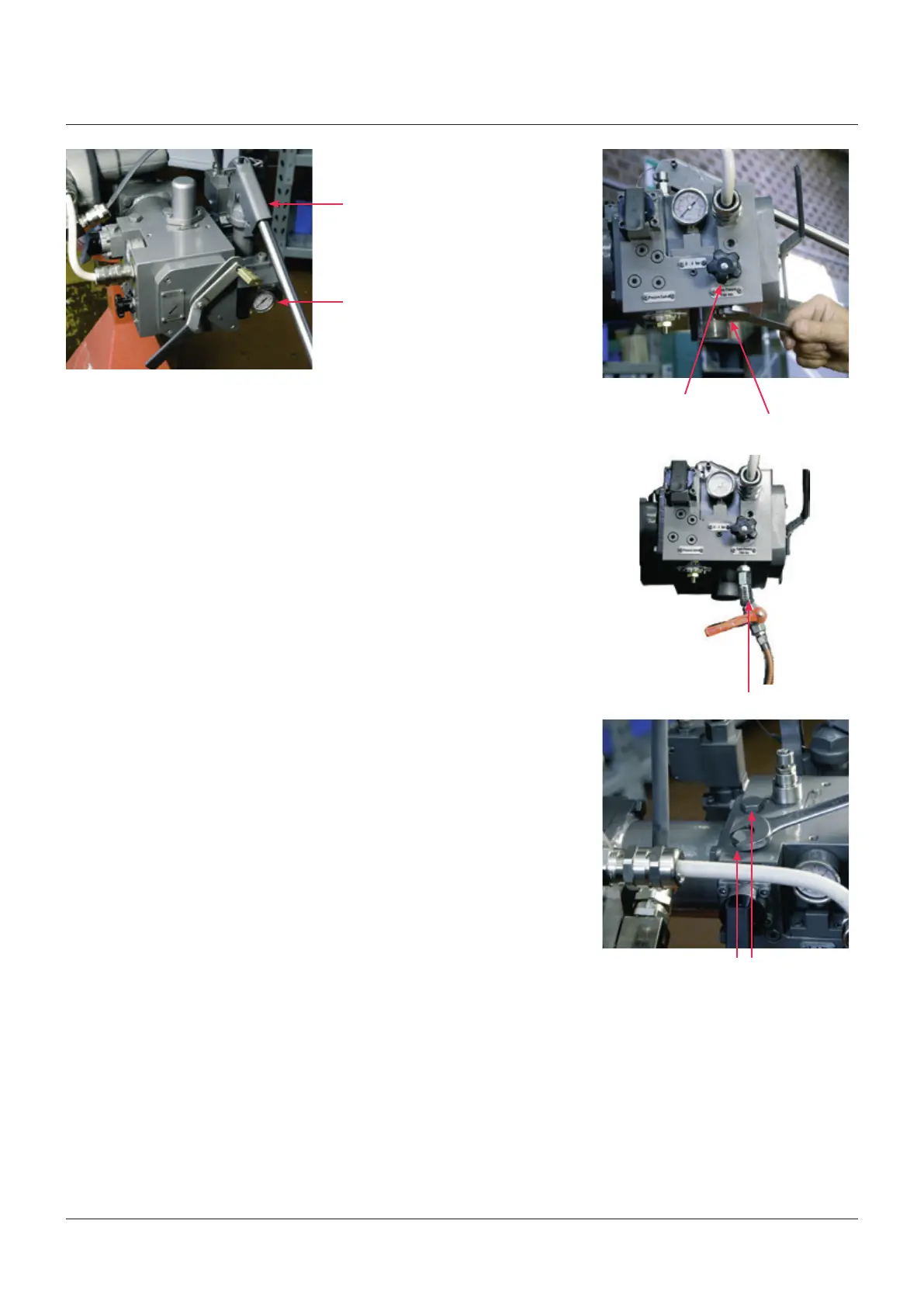

Hand pump

Drain/charge plug

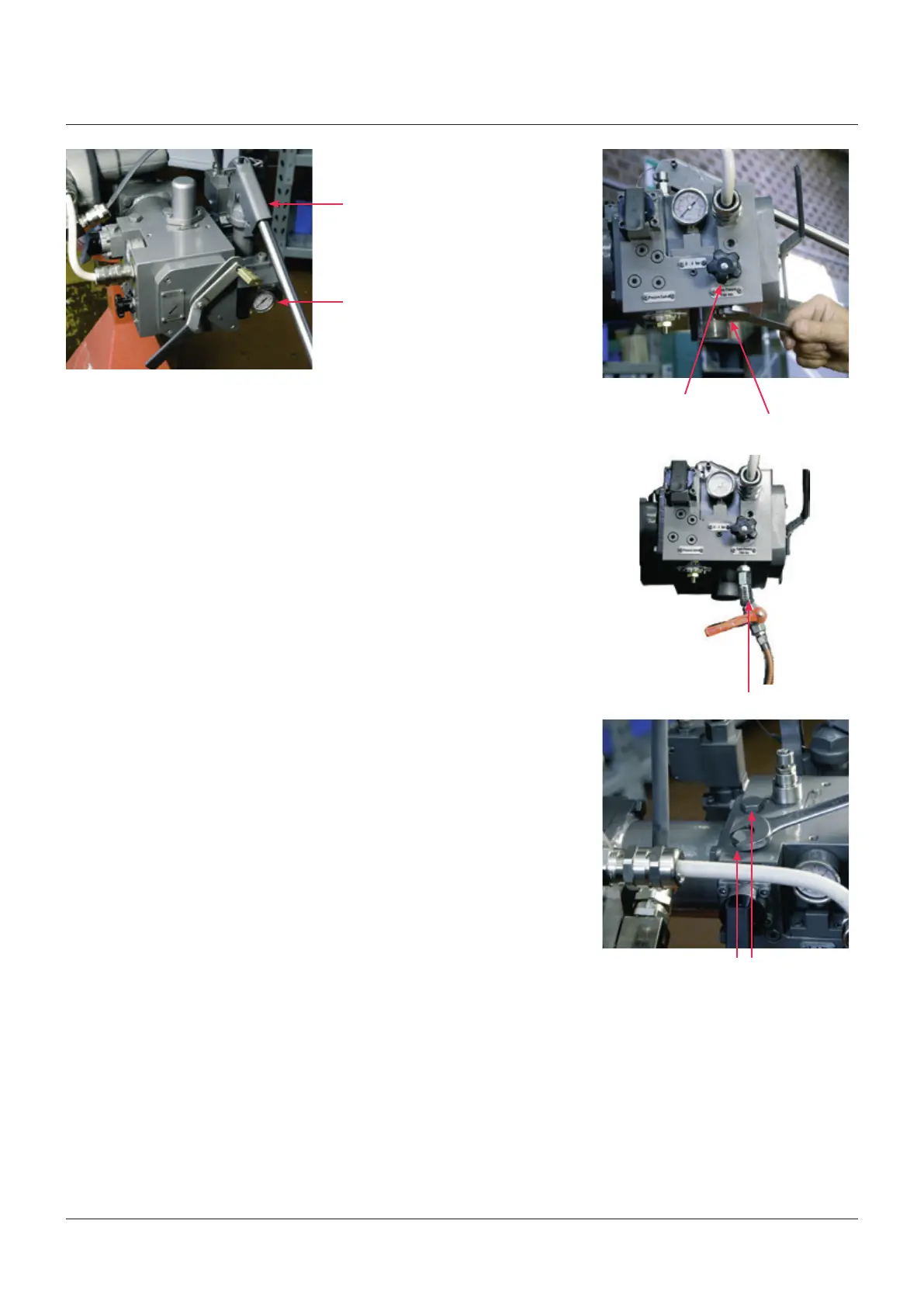

Needle valve (352)

High pressure manometer

WARNING!

For safety reasons it is required that at the end

of operation by hand pump, the lever is removed

from the hand pump yoke and the yoke is fixed

using the existing split pin.

If at the end of a manual operation, the actuator

is required to remain in the energized position,

it is necessary to leave the hydraulic selector in

MANUAL position.

To restore the electric mode function, the

hydraulic selector has to be moved to AUTO

position and, as soon the electrical power is

available, the red mushroom push-button has

to be pressed to RESET the actuator.

16.2.3 Accumulator recharge

The actuator is supplied with the accumulator

(30) charged at a 3bar pressure, with the

main spring in its released position (failsafe

condition).

If it is necessary to recharge the accumulator

during or after the field installation, or after

a maintenance intervention, the following

instructions have to be performed:

• Check if the actuator is really in failsafe

condition, with the main spring released;

press the REDmushroom push button to

ensure that the actuator is in the correct

position.

Purge

Plugs

¼” NPT hose

• Check that the needle valve (352) is

completely closed.

• Remove the drain/charge plug (P) by

unscrewing it.

• Connect a ¼” NPT hose to the drain/charge

hole, and fill the oil until the low pressure

manometer (621/BP) reaches a 3 bar

pressure.

• Open the needle valve (352).

• During the refill with oil, it is possible that air

is introduced inside the accumulator: this air

has to be leaked using the two leaking plugs

on the upper part of the manifold.

• Close the needle valve (352).

• Remove the ¼” NPT hose and close the drain/

charge hole with the drain/charge plug(P).

Loading...

Loading...