8

BIFFI FAIL SAFE ELECTRIC ACTUATORS, MODEL EFS2000V4

InstructIon and operatIng Manual

6.5 Safety instructions for installation in

hazardous area

6.5.1 Instructions for the explosion-proof

enclosures

IMPORTANT

Electric Actuator EFS2000v4 must be installed

and maintained according to the applicable

Rules regarding the electrical installation in

Hazardous areas (other than mines) classified

as zone 1 and/or 2 (gas) and zone 21 and/or 22

(dust) according to EN60079-10 (hazardous area

classification).

Example: EN60079-14 (electrical installation),

EN60079-17 (maintenance).

During the dismantling and subsequent

reassembling of the explosion-proof

enclosures (covers, cable glands, joints)

be careful to bring these enclosures back

to their original condition to maintain their

integrity. In particular, be sure the joint

surfaces of all enclosures are spread

with a film of recommended grease.

6.5.2 Installation in ambient temperature with

explosive dusts

IMPORTANT

Electric Actuator EFS2000v4 must be installed

and maintained according to the applicable

Rules regarding the electrical installation in

Hazardous areas (other than mines) classified as

zone 1 and/or 2 (gas) and zone 21 and/or 22 (dust)

according to IEC/EN60079-10 (hazardous area

classification).

Example: IEC/EN 60079-14 (electrical installation),

IEC/EN 60079-17 (maintenance).

Special attention must be paid to the following

points:

• Before assembly, the joint surfaces must be

greased with silicon oil or equivalent.

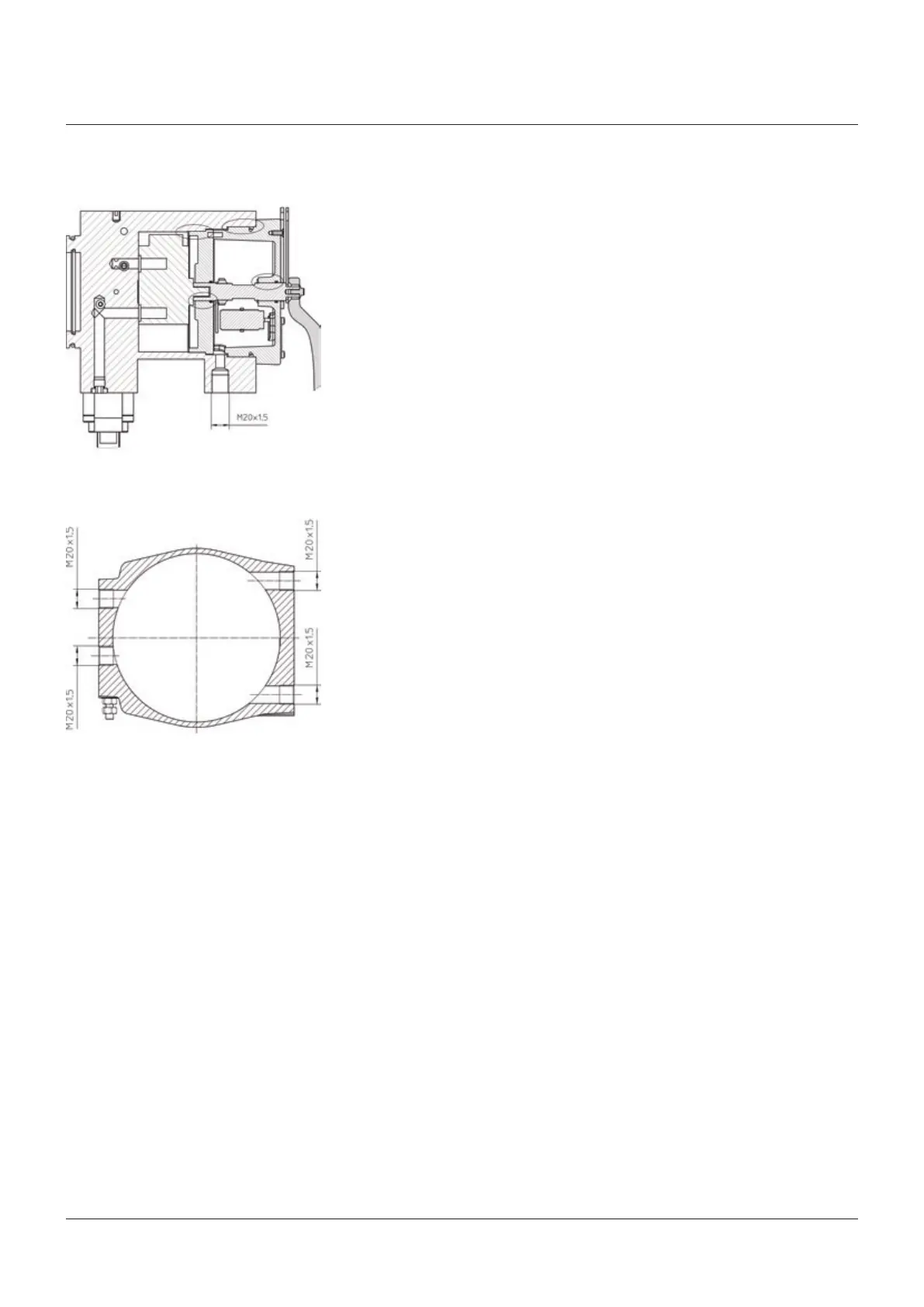

• The cable glands must have a protection

degree at minimum IP66/68 (EN 60529).

• Periodically verify the layer of dust deposited

on the enclosure and clean it in case the layer

is more than 5mm.

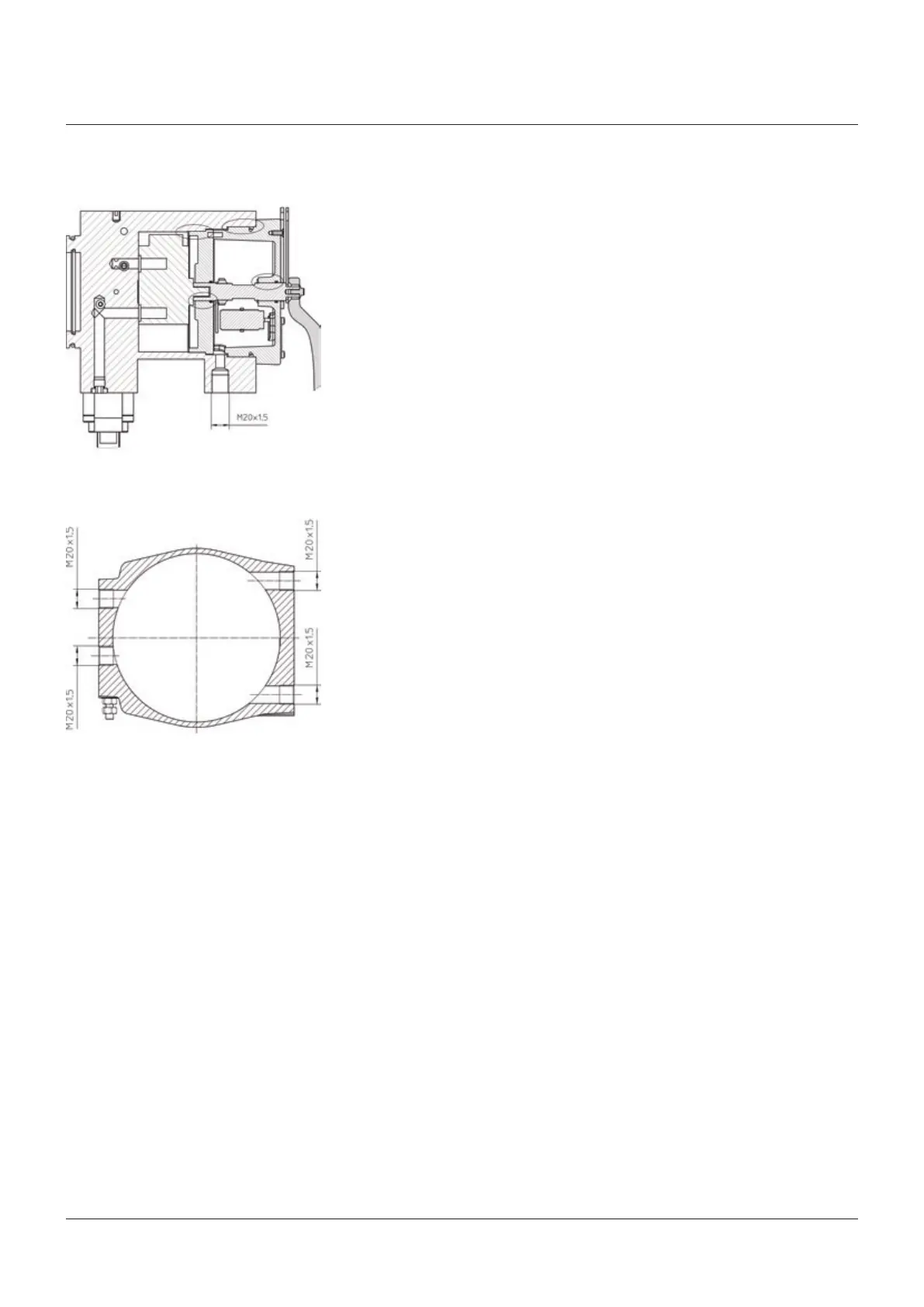

6.4.1 Entries on the manually operated electrical

switch enclosure

6.4.2 Entries on the electro-magnetic clutch

device enclosure

Procedure to be followed:

• Do not damage the explosion-proof mating

surfaces on the housing and on the electrical

enclosure covers.

• Reinstall all the screws that go with the

dismantled parts, and block them with a

thread sealant after spreading them with

a film of copper- or molybdenum-based

grease. This will keep screws from sticking

and make maintenance operations easier.

IMPORTANT

In case the screws of the cover or other parts

relevant to the explosion-proof protection must

been replaced check that new bolts and/or screws

are of the same dimension and quality as the

original ones as stated on the list of material

included on this manual, or of a better quality. In

case the screws of the cover must been replaced,

a SS AISI 316Class A4 Grade 70 must be used

with minimum yield strength of 450 N/mm

2

.

WARNING!

Do not electrically operate the EFS2000v4 when

the electrical enclosures are removed. Operating

the unit with the electrical enclosures removed

could cause personal injury.

• Replace the weatherproof seals that may

have been removed (O-ring for the covers,

O-ring forthe explosion-proof joint of the

motor).

Loading...

Loading...