Do you have a question about the BIGTREETECH EBB42 CAN and is the answer not in the manual?

Key features of the BIGTREETECH EBB42 CAN V1.0 board.

Technical specifications and parameters of the EBB42 CAN V1.0.

Supported firmware for the EBB42 CAN V1.0 board.

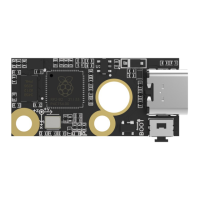

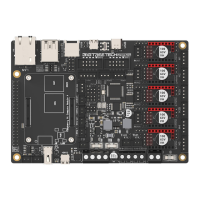

Physical dimensions and layout of the EBB42 CAN V1.0 board.

Detailed pinout configuration for the EBB42 CAN V1.0 board.

How to supply power to the board via USB.

Configuration for NTC and PT1000 thermistor settings.

Wiring diagram for connecting a BL-Touch sensor.

How to connect a filament runout sensor.

Wiring for RGB LED control.

Steps to compile Klipper firmware for the board.

Procedure for updating the board's firmware.

Setting up CANBus with U2C module.

Setting up CANBus with RPI-CAN HAT module.

The BIGTREETECH EBB42 CAN V1.0 is a specialized nozzle adapter board designed for 42 extruder stepper motors, developed by Shenzhen Big Tree Technology Co., Ltd. It offers flexible communication options, either via a USB port or a CAN BUS, significantly simplifying wiring setups for 3D printing applications. This board is primarily designed to work with Klipper firmware, providing a robust and adaptable solution for controlling extruder functions.

One of the key usage features of the EBB42 CAN V1.0 is its straightforward firmware update process. The board includes dedicated BOOT and RESET buttons, allowing users to easily update the firmware through DFU (Device Firmware Upgrade) mode via USB. This ensures that the board can always be kept up-to-date with the latest Klipper features and bug fixes. For those who prefer, firmware can also be updated via Raspberry Pi, or using STM32CubeProgrammer software when the board is connected to a computer and in DFU mode. Once the firmware is downloaded for the first time, subsequent updates do not require pressing the BOOT and RESET buttons again, streamlining the maintenance process.

The board incorporates several protection circuits to enhance reliability and user safety. A protection circuit on the thermistor input helps prevent damage to the main control chip that could be caused by leakage current from the heating rod. Additionally, anti-flyback diodes are integrated into the heating rod and fan ports. These diodes effectively protect the MOS tubes from being burned due to reverse voltage, a common issue in DIY setups. Furthermore, the power interface features anti-reverse connection protection, safeguarding the motherboard from damage if power lines are mistakenly connected in reverse during installation or modification.

For temperature sensing, the EBB42 CAN V1.0 offers versatile options. Users can select the thermistor's pull-up resistor values using jumper wires, making it compatible with PT1000 sensors (requiring 2.2K pull-up resistors) and simplifying DIY integration. For versions equipped with the MAX31865 chip, the board supports both 2-wire and 4-wire PT100/PT1000 configurations, which can be selected via a DIP switch. This flexibility allows users to choose the most suitable temperature sensing method for their specific needs, with the MAX31865 offering higher accuracy compared to direct thermistor readings. However, it is important to note that if the TH0 interface is not using a PT1000 sensor, the jump cap should not be inserted, as this would prevent the 100K NTC thermistor from functioning correctly.

The EBB42 CAN V1.0 also provides extensive expansion capabilities. It includes reserved I2C interfaces, which can be utilized for filament broke and clogged detection, as well as supporting various other DIY functions. The board features two CNC fan interfaces (FAN0, FAN1), with a maximum output current of 1A and a peak value of 1.5A per interface. The heating interface (E0) supports a maximum output current of 5A. Expansion interfaces for EndStop, I2C, Probe, RGB, PT100/PT1000, USB, and CAN are all available, offering comprehensive connectivity for a wide range of accessories and sensors commonly used in 3D printing. The onboard TMC2209 motor driver operates in UART mode, controlling the stepper motor via the EM interface.

Communication flexibility is a core aspect of this board. It supports communication via either CAN BUS or USB. When using CAN communication, a terminal resistor of 120R can be selected via a jumper cap, and additional CAN expansion interfaces are reserved. For USB communication, the board is equipped with an ESD protection chip on the USB port, which prevents damage to the main control board from static electricity. When powering the board via USB, a jumper cap must be used to short the VUSB pins, effectively isolating the main control board's DC-DC converter from the USB 5V supply. This also ensures that the board receives working voltage if there is no external power supply during firmware writing via USB. The DCDC 5V output provides a maximum current of 1A.

The physical design of the board is compact, with external dimensions of 40mm x 40mm and installation dimensions featuring 31mm x 31mm hole spacing with four M3 screw holes. The board comes with a variety of accessories, including terminals, female reeds, double-way studs, and screws, to facilitate DIY assembly and integration.

When configuring the board with Klipper, users need to access the Raspberry Pi's IP address in a browser to download the reference configuration files. It is crucial to update the Klipper firmware source code to the latest version if the required configuration files are not found. After uploading the board's configuration files to the Klipper configuration directory, users must include the specific configuration file (e.g., sample-bigtreetech-ebb-canbus-v1.0.cfg) in their printer.cfg file. Additionally, the ID number in the configuration files must be revised to match the actual ID of the board, whether communicating via USB serial or CANBus.

For CANBus configuration, specific steps are required. If using the BIGTREETECH U2C Module, users need to modify the network interfaces file on the Raspberry Pi to set up the CAN interface, including the bitrate (which must match the firmware's CAN bus speed). After saving the changes, the Raspberry Pi needs to be rebooted. To identify the CANBus devices, a script can be run to query the canbus_uuid of each microcontroller. If Klipper operates normally and connects to the device, it will not report a canbus_uuid, indicating a successful connection. If using the BIGTREETECH RPI-CAN HAT Module, additional modifications to the /boot/config.txt file are necessary to enable SPI and configure the MCP2515 CAN controller. After these modifications and a reboot, commands can be run to verify that the RPI-CAN HAT module is correctly connected and functioning.

In summary, the BIGTREETECH EBB42 CAN V1.0 is a feature-rich and well-protected adapter board that simplifies the integration of 42 extruder stepper motors into 3D printing systems, particularly those running Klipper firmware. Its design prioritizes ease of use, expandability, and reliability, making it a suitable choice for both experienced DIY enthusiasts and those looking for a streamlined solution for their extruder control needs.

| Compatibility | 3D Printers |

|---|---|

| Communication Protocol | CAN |

| Architecture | ARM Cortex-M0+ |

| Logic Voltage | 3.3V |

| Thermistor Input | 1 |

| Heater Cartridge | 1 |

| Fan Ports | 2 |

| RGB Light | Yes |

| Driver | TMC2209 |

| Supported Firmware | Klipper |

| CAN Interface | Yes |

| Max Current | 2A |

| Communication Interface | UART |