1 - Assembly machine setup

1.2 - Connecting to compressed air system

1.3 - Electrical connection

ATTENTION:

During the following procedure, the drill unit (3.23)

makes an upward motion

1.2.1) Connecting air supply

• Connect the air supply to the air filter unit (1.8) of the assembly machine

• Open stop valve

Important:

A rapid hose coupling must be inserted a max. 3 m from the machine in

the air pressure supply line.

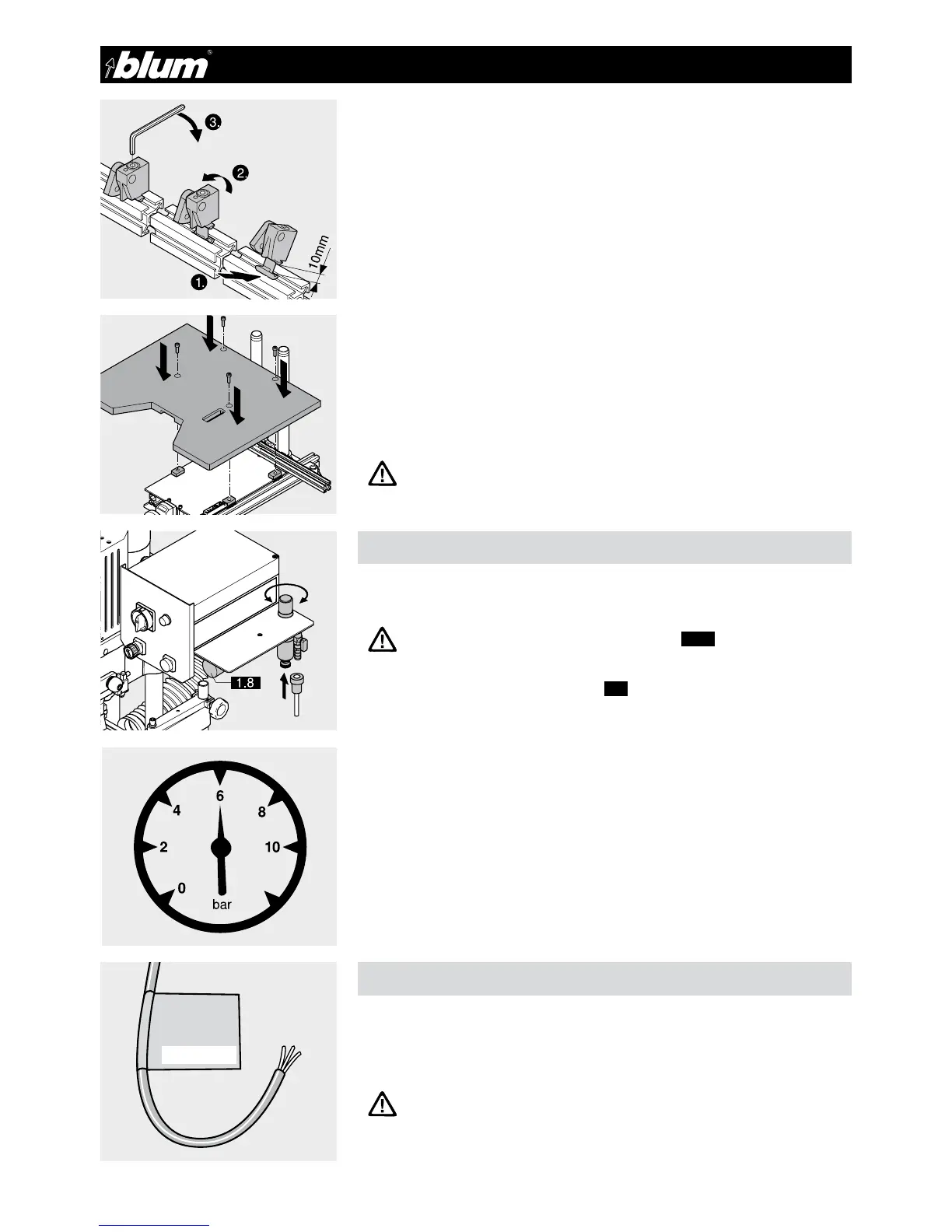

1.2.2) Setting operating pressure

• The operating pressure is 6 bar

(Pmin = 5 bar)

(Pmin = 7 bar)

• Air consumption per work cycle is 1.5 litres

1.3.1) Electrical connection

ATTENTION:

The electrical connection must be performed by a qualified electrician!

1.1.5) Attaching work table

a) Accessory work top MZA.5300 table

• Set work table on runner plate

• Attach work table to runner plate

b) User-supplied work table (see Chapter 8 - Appendix)

ATTENTION:

The assembly machine should not be operated without the work top.

The work top must be securely fastened to the assembly machine using

the included fixing screws.

• The assembly machine is equipped with a mains plug. If the mains plug cannot be

used, the following steps should be carried out:

1.1.4) Attaching swivel stops

• Loosen clamping knob until the counter plate protrudes 10 mm

• Attach swivel stop to ruler at an angle and stand upright

• Tighten clamping knob

Note:

This procedure can also be used to set a stop between two available

stops.

!

!

Loading...

Loading...