6.1 - Maintenance

6 - Maintenance and service

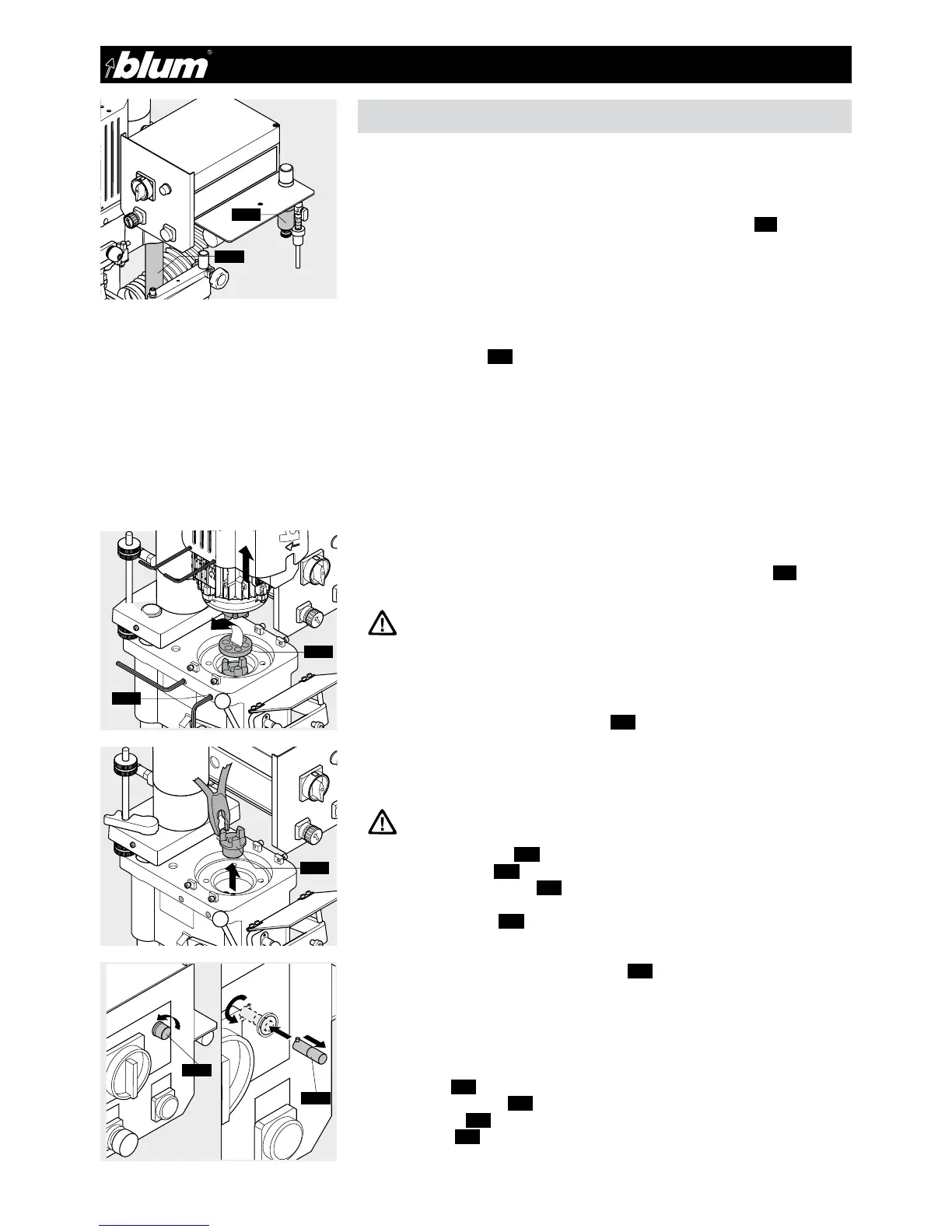

6.1.2) Damaged coupling

The coupling is damaged if:

• The drill is jammed in the work piece but the motor fan wheel continues (1.9) to turn.

• Set main switch to pos. 0

• Disconnect electrical and pneumatic connections to the assembly machine

• Remove drill

• Remove motor hood

• Loosen the motor’s four side fixing screws (6.4)

(approx. 4 full turns)

• Lift up motor and place on to the drive

• Remove dampening ring (6.5)

• Remove old coupling (6.6)

• Attach replacement coupling (6.6) on to the spindle. (ensure correct positioning of

coupling and spindle)

• Insert dampening ring (6.5)

• Preposition coupling base for motor attachment

• Attach motor (motor must sit securely on the flange)

• Re-secure the motor’s four side fixing screws (6.4)

• Re-attach motor hood

6.1.3) Replacing the operational status indicator

• Disconnect assembly machine from the power supply.

• Set main switch to pos. 0

• Remove front (6.7) from the operational status indicator. (unscrew)

• Remove defective lamp (6.8). (Press and turn to the left)

• Install new lamp (6.8). (Press and turn to the right)

• Reattach front (6.7) to the operating mode display indicator.

• The supports are maintenance free and should not be oiled

• The guide elements (6.2) must be cleaned regularly with a dry cloth to remove dust.

(Do not use cleaners or solvents)

6.1.1) Maintenance

• Drilling dust should be removed from the assembly machine on a regular basis

• Before using the machine, you should always check the air filter unit (6.1) for water

which may accumulate there. Empty the unit if necessary.

• Before every use of the machine, check the pneumatic lines and electrical lines for

damage.

ATTENTION:

Keep your hands and other objects away from machine work area (A)

ATTENTION:

Secure the motor against falling

6.4

6.5

6.6

Loading...

Loading...