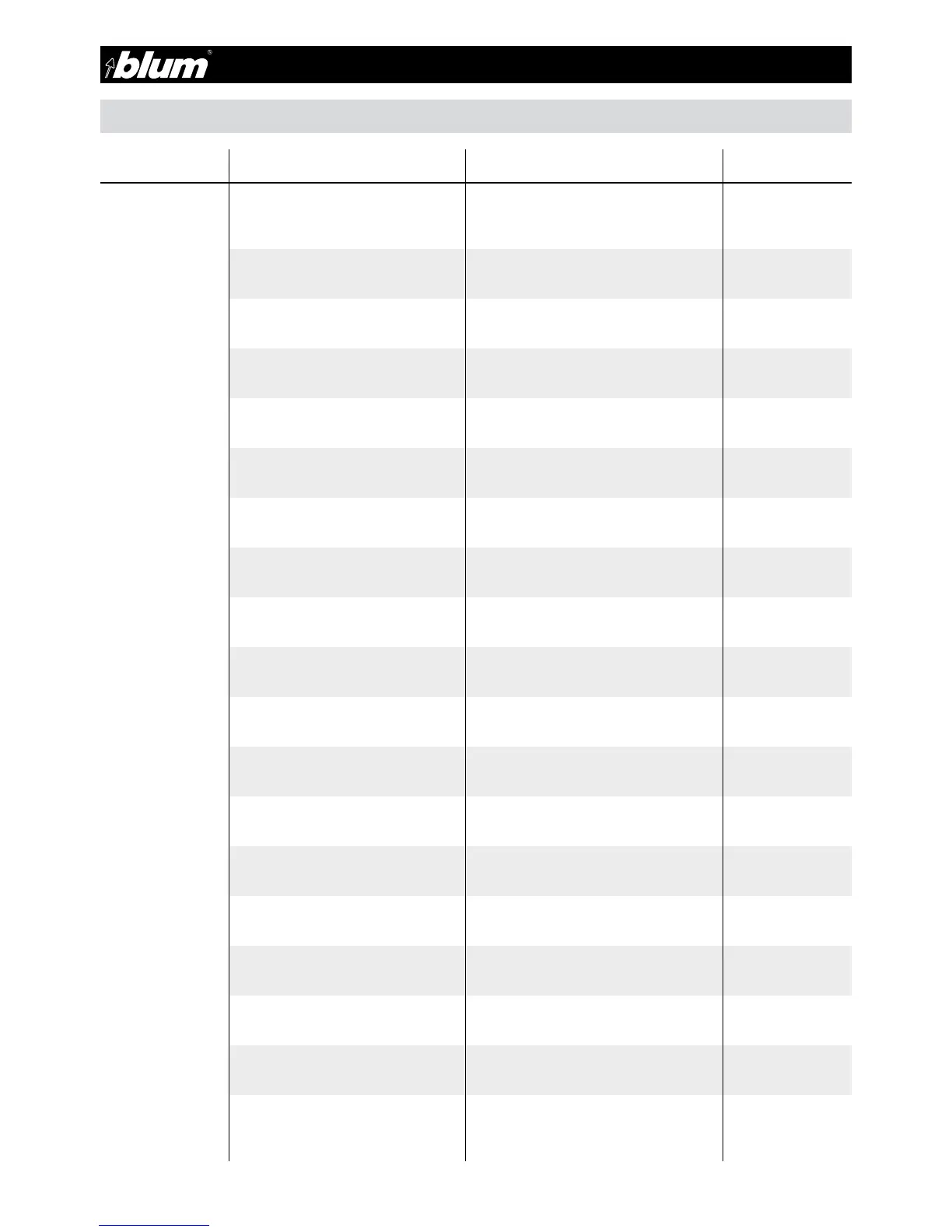

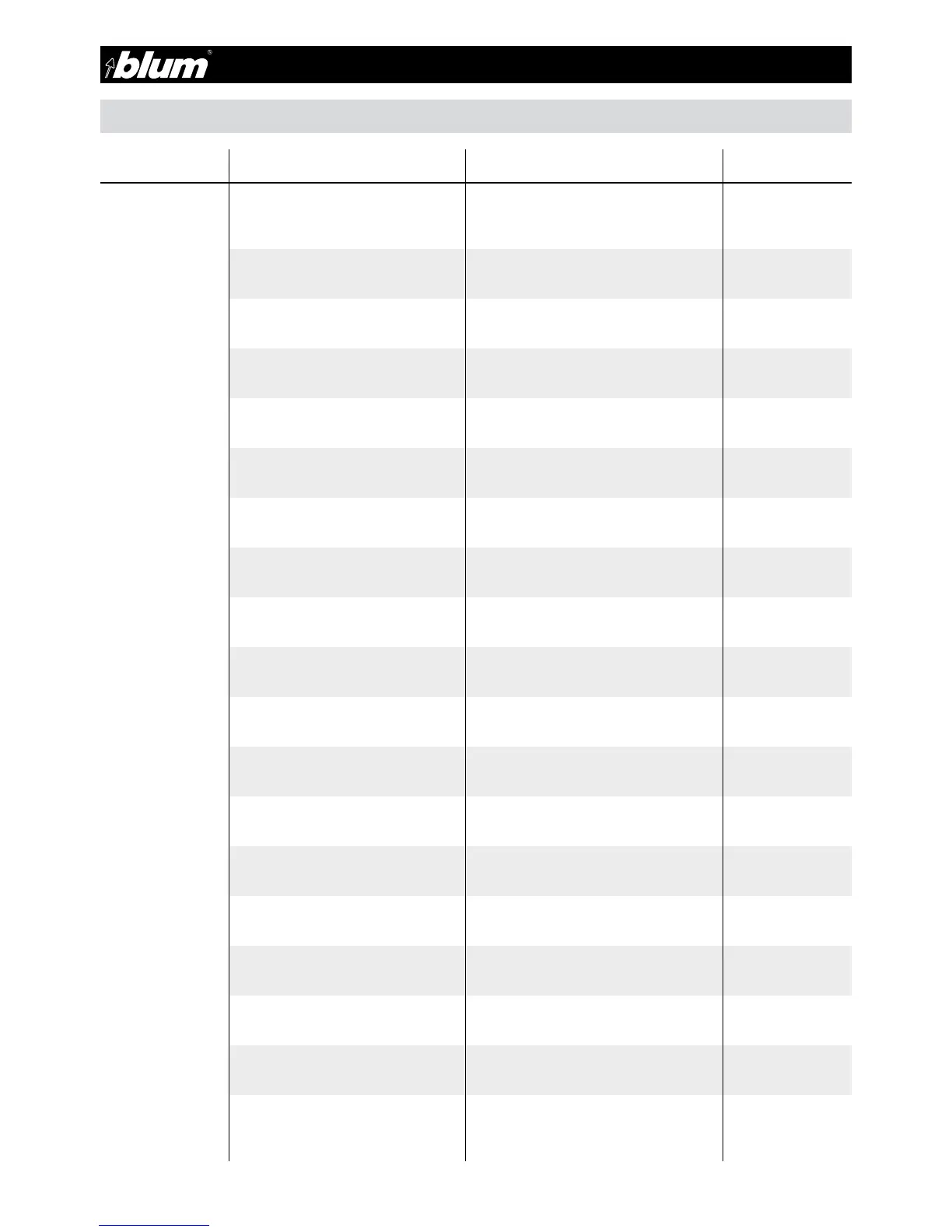

7 - Troubleshooting

Clamps do not func-

tion (optional)

Incorrect clamp switch position Change clamp switch position See point 2.1.3

Clamp valve defective

Neon bulb defective

Drive circuit fuse defective

Bracket fitting is loose or defective

Replace clamp valve

Replace neon bulb

Have an authorised electrician replace the

drive circuit fuse

Attach bracket fitting or replace

none

See point 6.1.3

none

none

Other problems Replace air filter none

Replace hoseHose is kinked or not tight none

Chip blow-off is displaced Correct chip blow-off by turning the blow-off

hose

none

Operational status

indicator does not

light

Air filter is not tight

Chip blow-off is

defective

Gearbox defective

Support, spindles or gears are damaged Replace gearbox none

Error Cause Solution Comment

7.3 - Function errors

Assembly machine is not connected to

the air supply

Air pressure is too low

Pneumatic hose is kinked or damaged

Restrictor for setting the cam speed is

closed

Connect assembly machine to the air supply

Adjust air pressure (5-7 bar)

Check air lines

Open restrictor

See point 1.2.1

See point 1.2.2

none

See point 3.1.9

Feed key valve is jammed Replace valve none

Cylinder defective Replace cylinder none

Stroke movement

missing out when

feed switch is acti-

vated

Motor overheats Assembly machine connected to the

wrong voltage

Check mains voltage and compare with

motor data. Have checked by authorised

electrician

See electrical dia-

gram

Drilling in hard wood with too high a

speed

Reduce cam speed See point 3.1.7

Motor hood is dirty or covered by some-

thing

Remove objects and chips in the area of the

motor hood

none

Loading...

Loading...