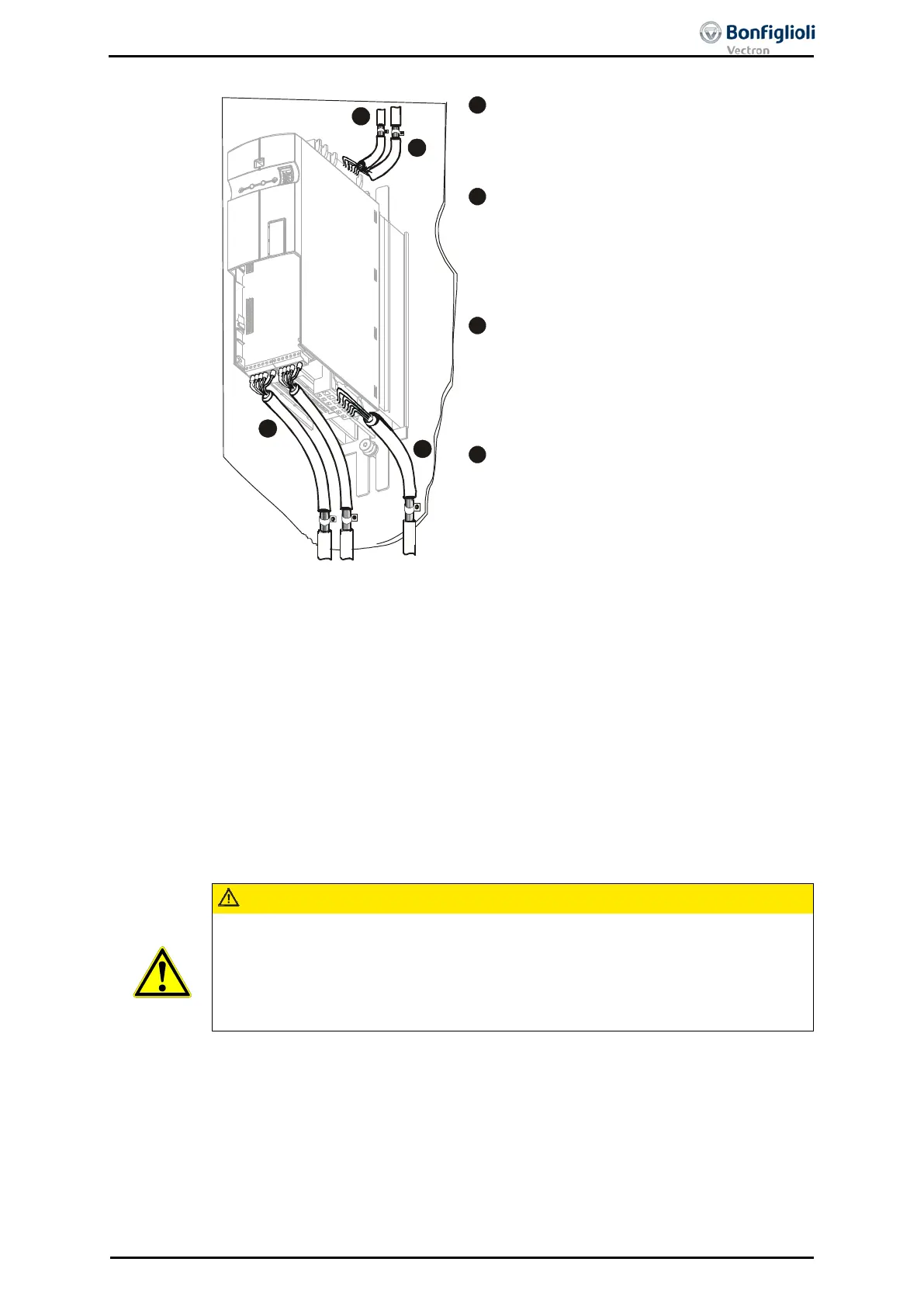

The length of the mains supply cable is not lim-

ited. However, it must be installed separate from

the control, data and motor cables.

The frequency inverters are to be connected to

the same mains potential or a common

direct

voltage source. Cables longer than 300 mm are

to be shielded. The shield must be connected to

the mounting panel on both sides.

Keep control and signal cables physically sepa-

rate from

the power cables. Analog signal lines

are to be con

nected to the shield potential on

one side. Install sensor cables separate from

motor cables.

The shield of the motor cable is to be connected

to ground potential properly on both sides. On

the motor side use a metal compression gland.

On the frequency inverter side an appropriate

shield clamp is to be used. The signal cable used

for monitoring the motor temperature must be

kept separate

from the motor cable. Connect the

shield of this line on both sides. If a brake resis-

tor is used, the connection cable must also be

shielded, and the shield is to be connected to

earth potential on both sides.

Line chokes reduce mains

harmonics and reactive power. Additional the increase of

product life is possible. Consider the reduction of the maximum output voltage if a

line choke is installed.

The line choke must be installed between mains connection and input filter.

Input filters reduce the conducted radio-

frequency interference voltage. The input

filter must be installed upstream on mains side of the frequency inverter.

CAUTION

The frequency inverters meet the requirements of the low-voltage direc-tive

2006/95/EC and the requirements of the EMC directive 2004/108/EC. The EMC prod-

uct standard EN 61800-

3 relates to the drive system. The documentation provides

information on how the applicable standards can be complied if the frequency invert-

er is a component of the drive system. The declaration of conformity is to be issued

by the supplier of the drive system.

06/13 Operating Instructions ACU 51

Loading...

Loading...