Installation

9

AWE – 6721835317 (2021/09)

5.4 Connection

5.4.1 Connecting the indoor unit to the heat pump and the

heating system

NOTICE

Residue in the pipework can damage the system.

Solids, metal/plastic filings, flux and thread tape residue and similar

material can get stuck in pumps, valves and heat exchangers.

▶ Keep foreign bodies from entering the pipework.

▶ Do not leave pipe parts and connections directly on the ground.

▶ When deburring, make sure that no residue remains in the pipe.

▶ Before connecting the heat pump and indoor unit, rinse the pipe

system to remove any foreign bodies.

NOTICE

Material damage from frost!

In case of a power outage the water in the pipes may freeze.

▶ Use insulation with a thickness of at least 19 mm for pipework

outdoors.

▶ In buildings, use insulation with a thickness of at least 12 mm for

pipework. This is also important for safe and efficient DHW mode.

All heat-conducting pipework must be provided with suitable thermal

insulation according to applicable regulations.

In cooling mode, all connections and lines must be insulated according to

applicable standards to prevent condensation.

▶ Route a leakage water hose downwards to a frost-free drain.

▶ Size pipework as specified in the installation instructions for the heat

pump.

▶ Connect the piping from the heat pump to the heat transfer medium

inlet.

▶ Connect the piping to the heat pump at the heat transfer medium

outlet.

▶ Connect the return from the heating system.

▶ Connect the flow to the heating system.

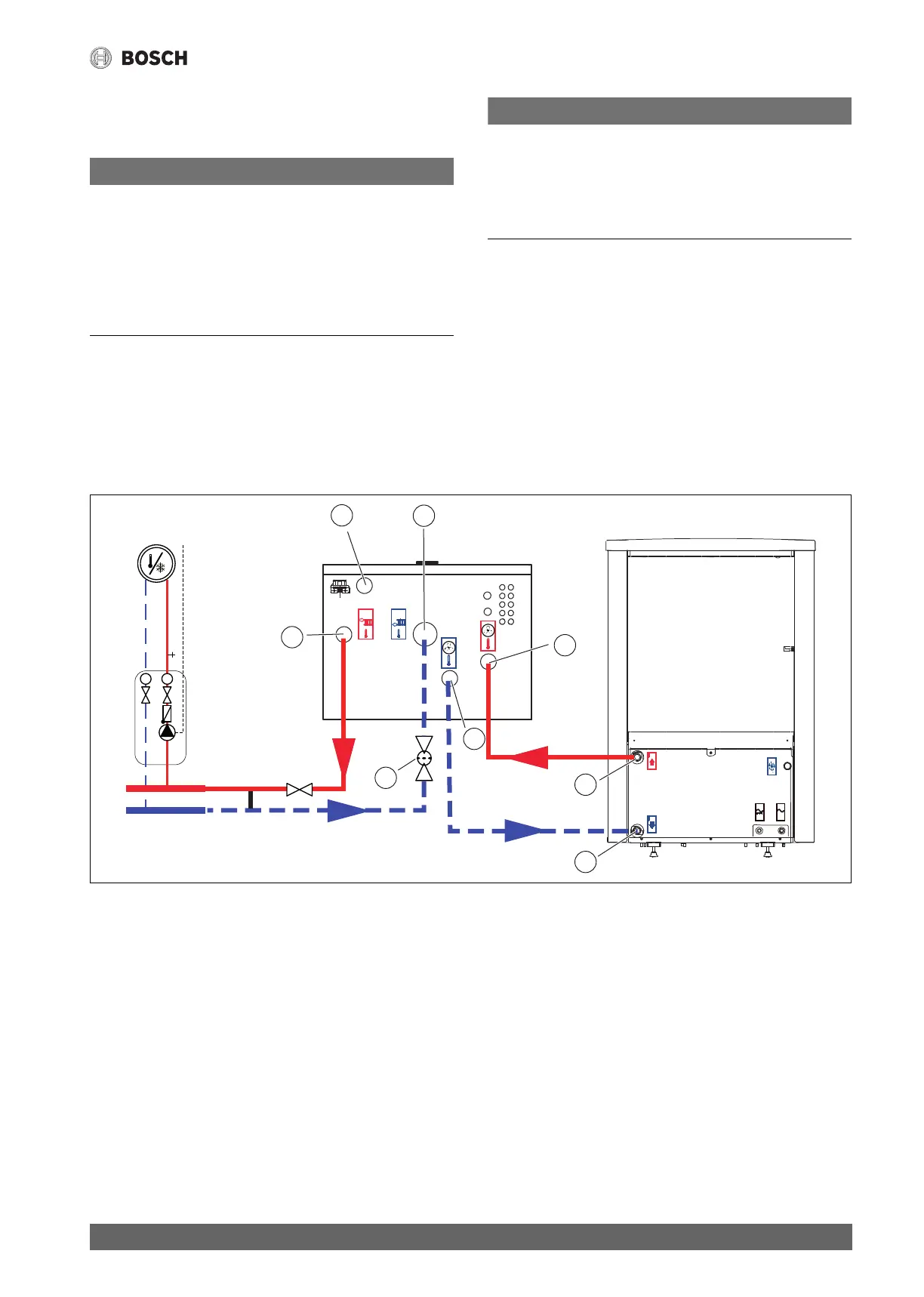

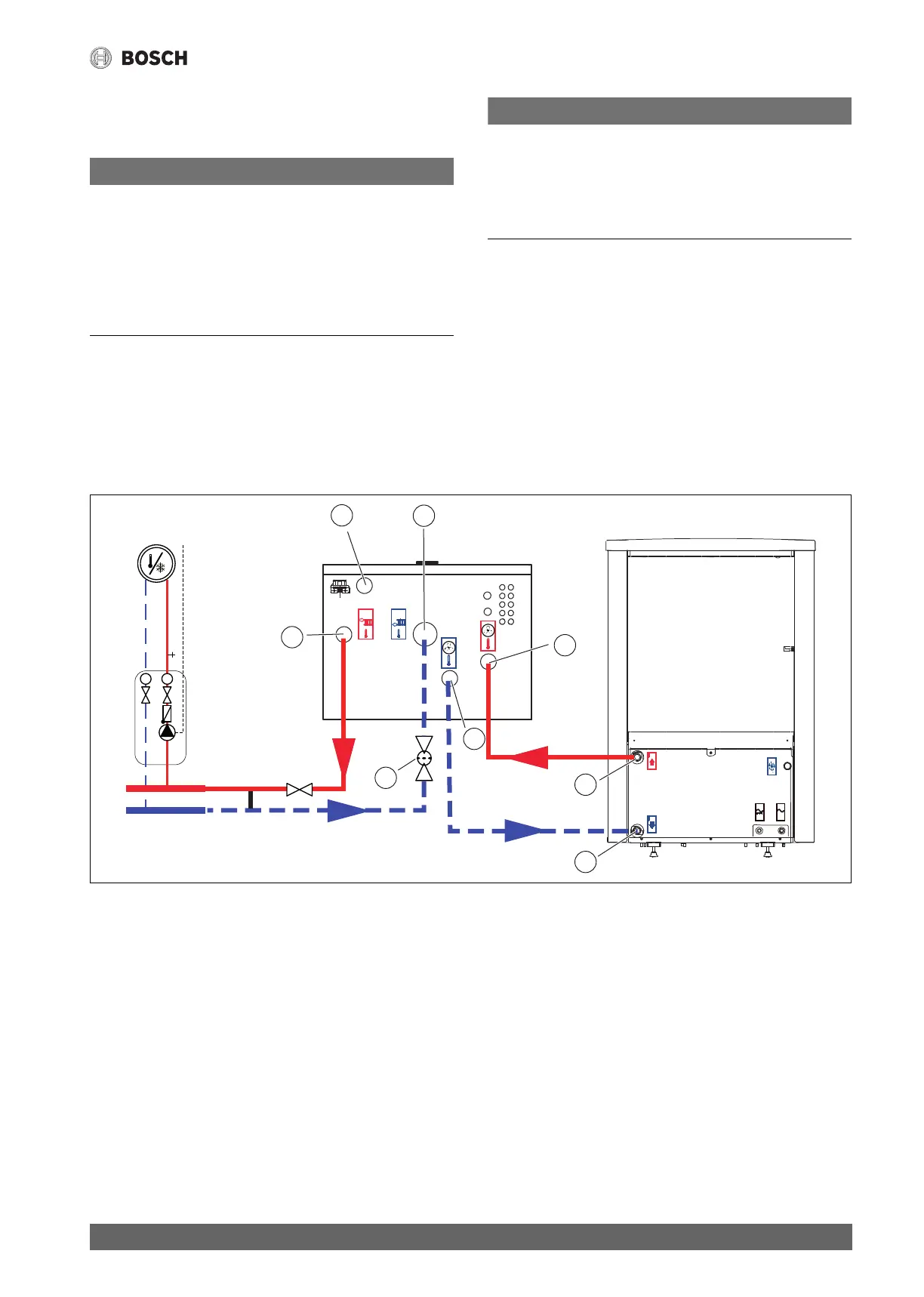

Fig. 6 Connection of the indoor unit with electric booster heater to the heat pump and heating system

[1] Heat transfer medium inlet (primary) from the heat pump

[2] Heat transfer medium outlet (primary) to the heat pump

[3] Flow from the heat pump

[4] Return to the heat pump

[5] Flow to the heating system

[6] Overpressure discharge from the pressure relief valve

[7] Return from the heating system

[8] Particle filter

T T

<50V 230V

/

400V

6

7

5

1

8

2

3

4

Loading...

Loading...