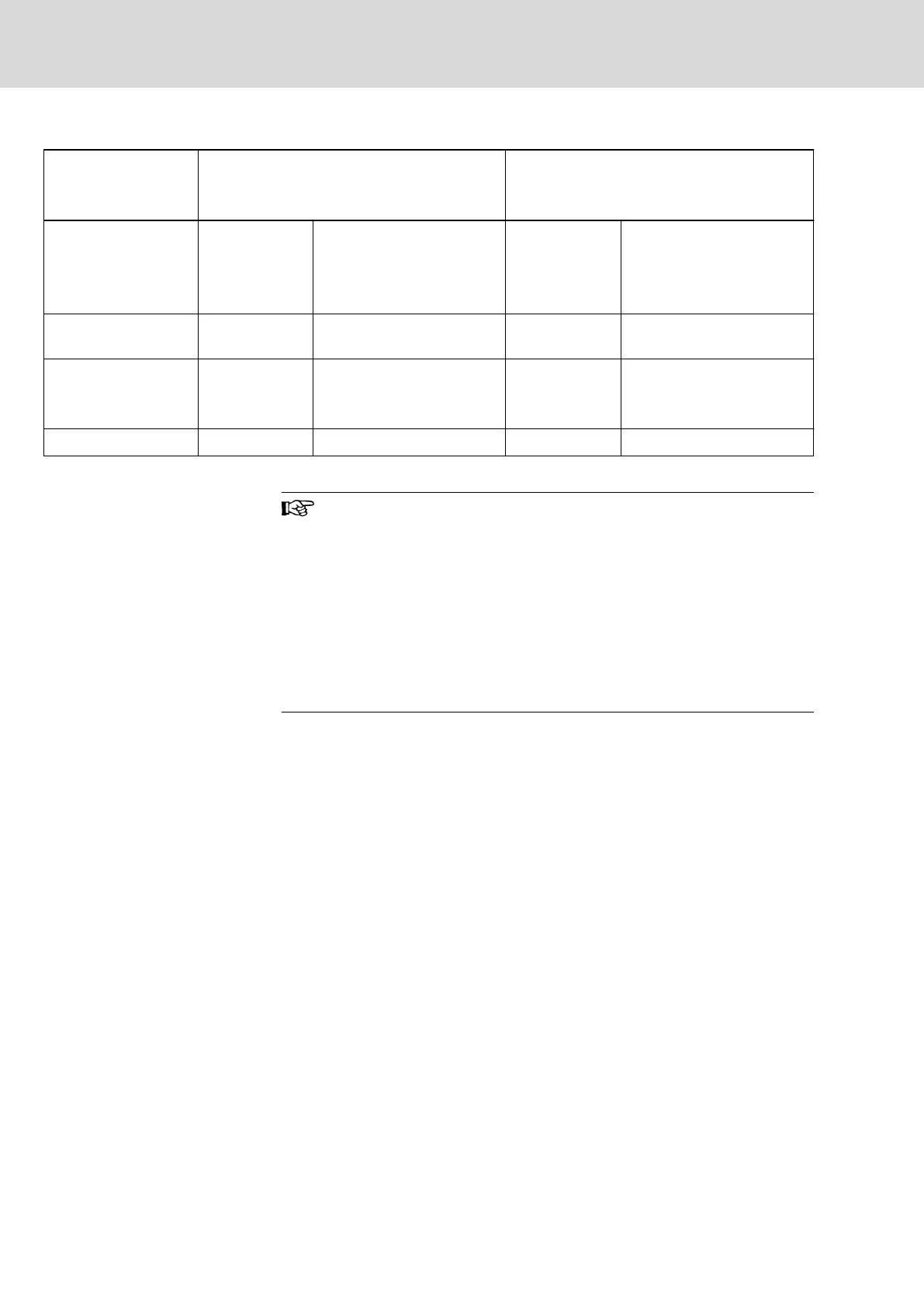

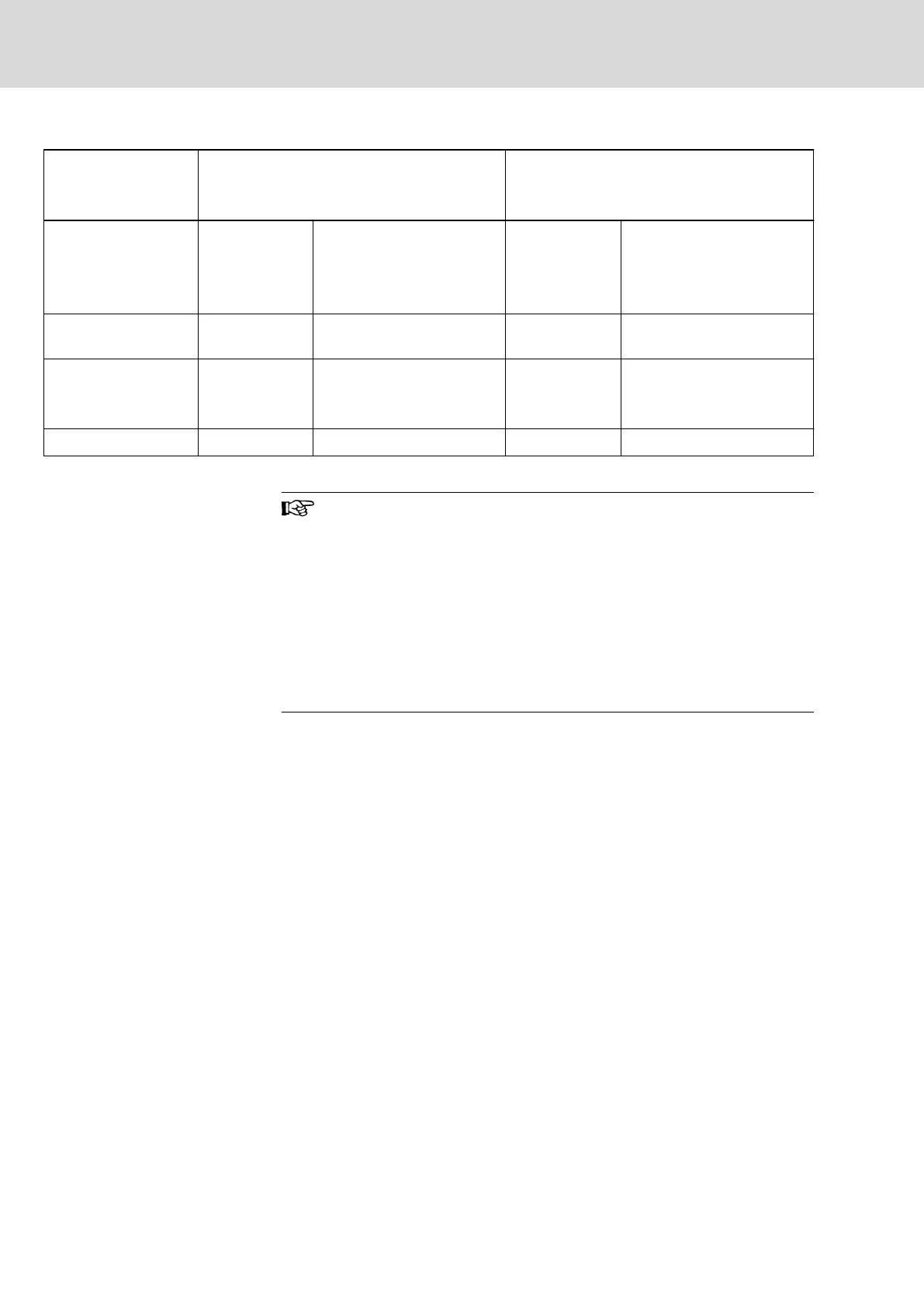

Selection

of the safety functions, i.e. transition from

normal operation ("bb/Ab")

Deselection

of the safety functions, i.e. transition to normal

operation ("bb/Ab")

STO

"Safe Torque

Off"

SBC

"Safe Brake Control"

(only with optional safety

technology module

"L4")

STO

"Safe Torque

Off"

SBC

"Safe Brake Control"

(only with optional safety

technology module "L4")

IndraDrive Cs Up to 18 ms

Up to 18 ms + clamping

delay of the brake

20 ms 20 ms

IndraDrive Mi

IndraDrive M /

IndraDrive C

Up to 18 ms - 20 ms -

IndraDrive ML 108 ms - 120 ms -

Tab. 4-5: Reaction times of integrated safety technology

The above-mentioned reaction times only apply to the safety

functions. To determine the total

reaction time of the system, take

the following aspects, among other things, into account:

● When selecting the safety functions

– Time until at least a single-channel selection greater

than 1 ms exists

● When deselecting the safety functions

– Time until an error-free dual-channel deselection exists

– Reaction time of the drive system after the setting of

drive enable (put motor under current, release brake)

4.5 Safety characteristics of the safety system

4.5.1 Introduction

IndraDrive Cs

For using the optional

safety technology modules "L3" and "L4", the

IndraDrive Cs system has been certified according to IEC 61508,

IEC 61800-5-2, IEC 62061 and ISO 13849-1.

IndraDrive Mi

For using the optional safety technology module "L3", the IndraDrive Mi

system has been certified according to IEC 61508, IEC 61800-5-2,

IEC 62061 and ISO 13849-1.

IndraDrive C / IndraDrive M

For using the optional safety technology module "L3", the IndraDrive C /

IndraDrive M system has been certified according to IEC 61508,

IEC 61800-5-2, IEC 62061 and ISO 13849-1.

IndraDrive ML

The certification of the IndraDrive ML system for using the optional safety

technology module "L3" according to IEC 61508, IEC 61800-5-2, IEC 62061

and ISO 13849-1 is in preparation.

IndraDrive Cs, IndraDrive Mi,

IndraDrive C, IndraDrive M and

IndraDrive ML

The risk assessment and risk reduction of a machine require assessing the

safety functions of the individual components. The interaction of the

components must be taken into account, too. In addition to the systematic

suitability, it is also necessary to determine the total PFH value for the

machine or the machine part (e.g., a safety zone). The total PFH value allows

judging whether the required "Safety Integrity Levels" (SIL) or "Performance

Levels" (PL) have been complied with. As regards the optional safety

Bosch Rexroth AG DOK-INDRV*-SI3-**VRS**-AP06-EN-P

Rexroth IndraDrive Integrated Safety Technology "Safe Torque Off" (as of MPx-16)

40/149

System overview

LSA Control S.L. www.lsa-control.com comercial@lsa-control.com (+34) 960 62 43 01

Loading...

Loading...