3-7

ROTATION BEARING LUBRICATION

There is one grease zerk in a hole on the right-hand side of the turntable base plate.

This should be used to lubricate the bearing every 50 hours. Rotate the turntable about

45º and pump some grease into the zerk. Repeat until the turntable has rotated two

revolutions. Use about 4 ounces (120 mL) of grease each time the bearing is lubricated.

Also, lubricate the gear teeth of the rotation bearing at the 50-hour interval. Remove the

pinion cover. Brush open gear grease, such as Mobilkote-S, on the teeth on each side of

the pinion at four places around the bearing. Rotate the boom several times and check

the coverage of the grease on all of the teeth. Replace the pinion cover.

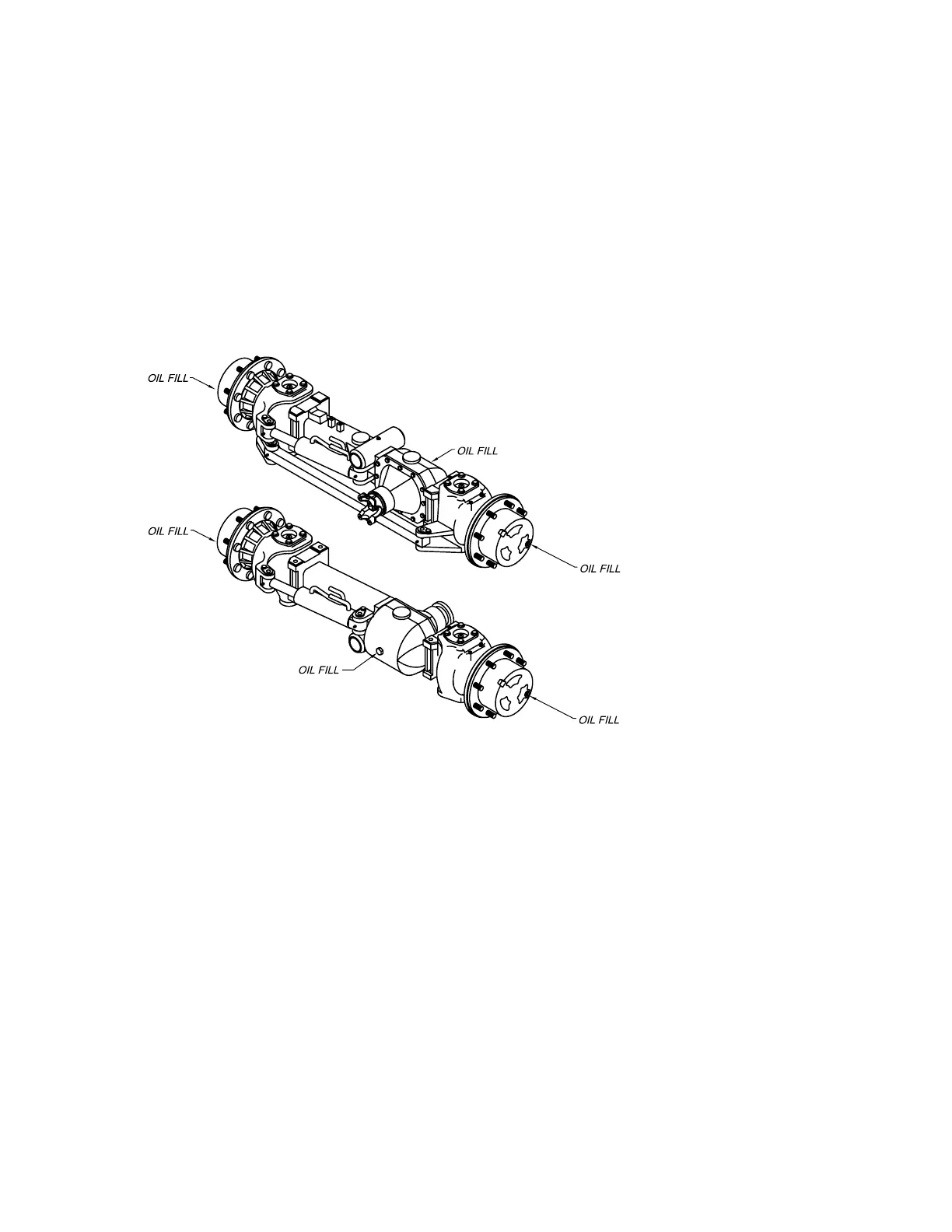

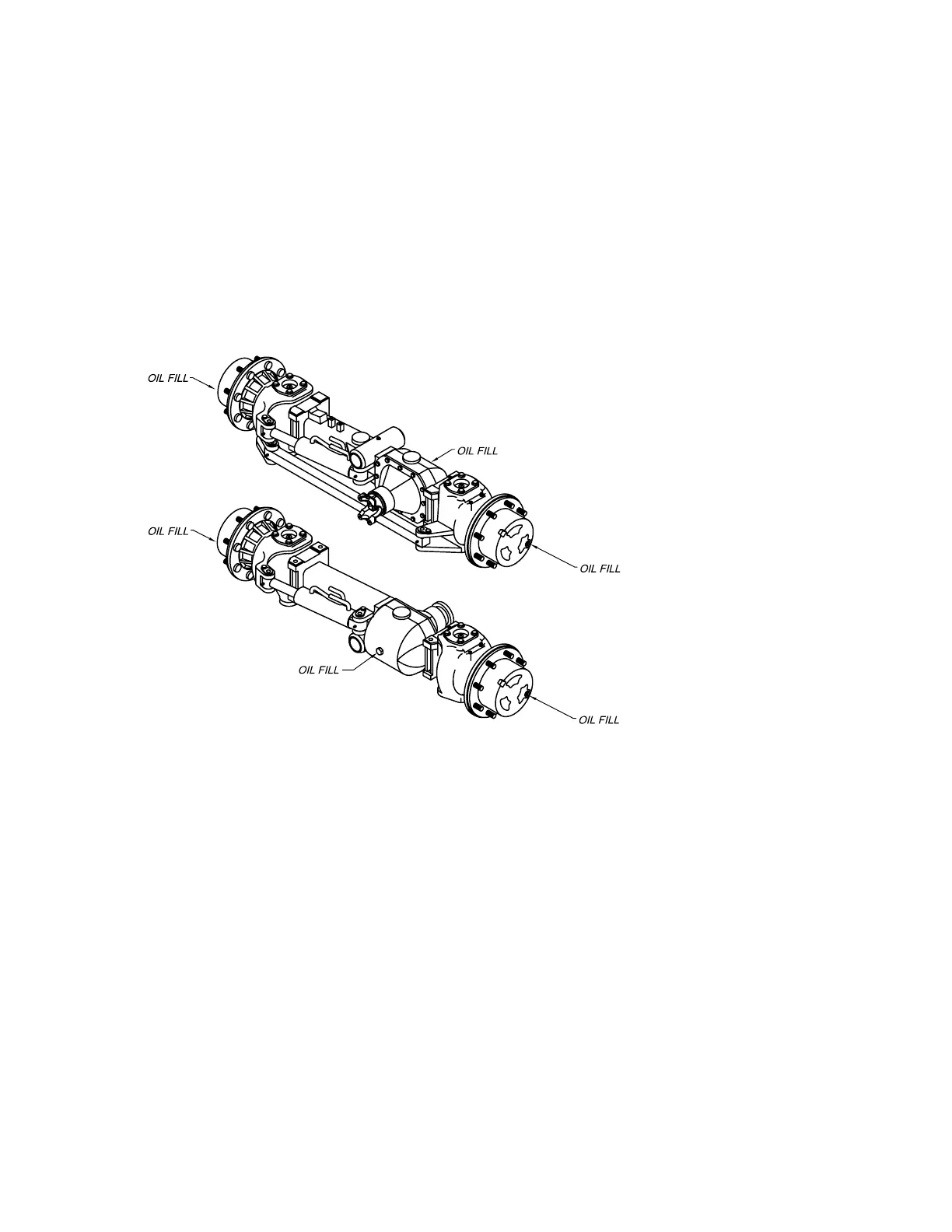

AXLES

Use Mobil 424

or equivalent.

Check oil level every 50

hours.

Drain and refill after

1,000 hours of operation

or after one year of ser-

vice, whichever comes

first.

WIRE ROPE LUBRICATION

The wire rope should be cleaned and lubricated every 50 hours of normal operation and

more frequently when used in dirty or corrosive environments. Whenever the rope is dirty

or dry, it should be serviced.

The rope should be cleaned with solvent and compressed air, or solvent and rags. A

wire brush may be used for difficult areas.

The recommended lubricant is AMOVIS #2-X. It should be sprayed or dripped onto the

rope where it is bent, as it passes over the tip sheave. Wrap rags around the wire rope

behind the sheave, and swab the excess oil that is carried along on the rope. Always

wear heavy leather gloves when handling wire rope.

Loading...

Loading...