IsoMet 5000 Precision Saw Application Guide

68

MA112780_38.6 [Original Instructions] 9/19/2011

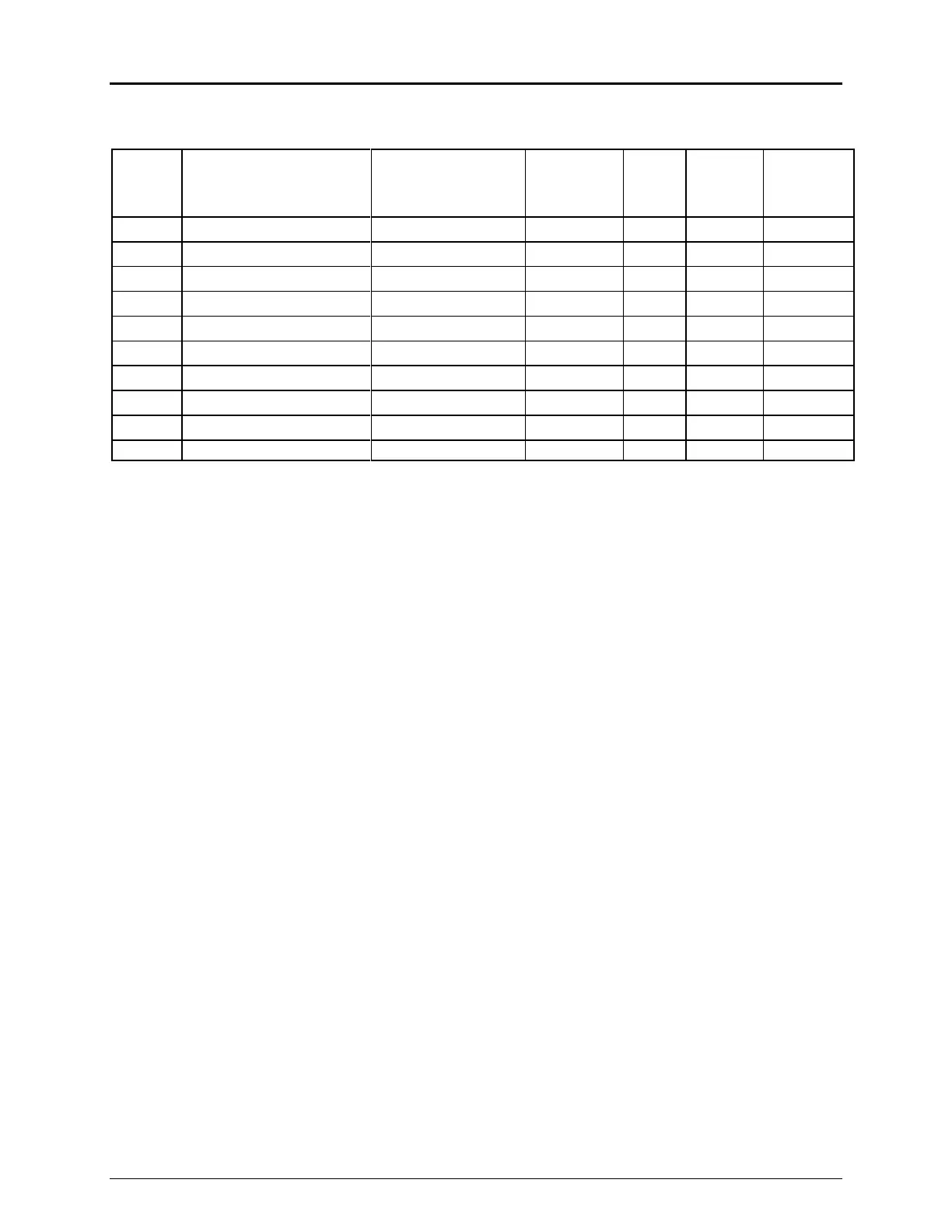

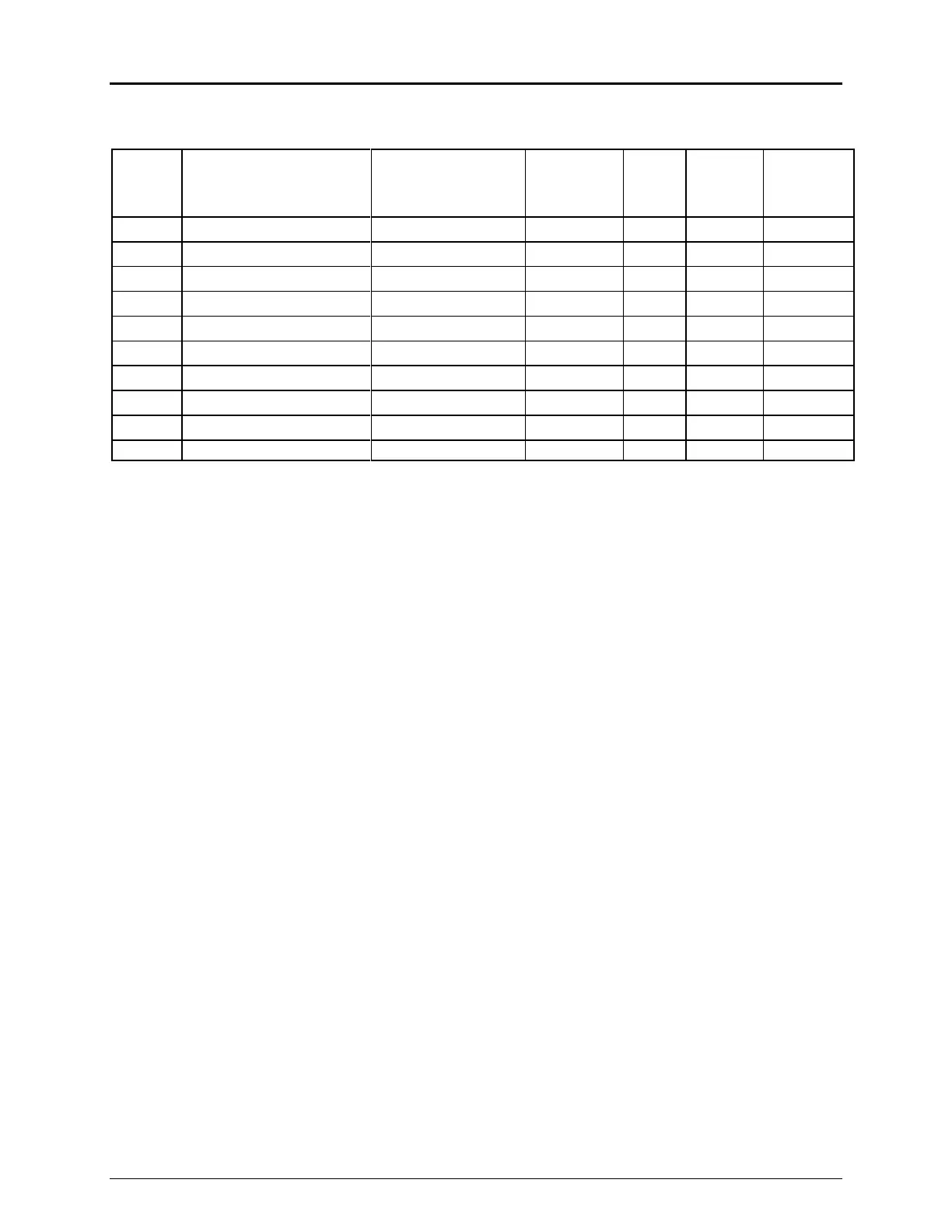

Estimated

Cutting

Time

(min:sec)

Turbine blades - ferrous base

Turbine blades - Titanium

1

0.29" (6 mm) x .125"(3 mm) rectangular section

2

0.67" (17 mm) diameter

3

0.570" (15 mm) diameter

4

0.74" (19 mm) diameter

5

1" (25 mm) x .25" (6 mm) rectangular section

6

0.375" (0.95 mm) diameter

7

BU01 - BU24 based on a 5-inch blade

8

BU25 - BU35 based on a 7-inch blade

Reduce speed to 0.2"/min, 5 mm/min when using ACU-THIN Blades (Part Number 10-4060-010 and 10-4061-

010)

ISOCUT

®

Blades can be substituted for 15 HC Blades in the table above for steels, cast iron, and carbide

materials.

These are general guidelines. Consider the individual application and adjust the parameters to meet the

application.

Loading...

Loading...