Bunn-O-Matic Corporation

29

spitting or excessive steaMing

(cont.)

3. control board

Check/replace

breWer is Making unusual noises 1. pluMbing lines

Plumbing lines should not rest on the counter

top.

“ “ 2. Water supply

The brewer must be connected to a cold

water supply.

“ “ 3. liMe build up

Remove the tank lid and clean inside of tank

with a deliming agent, if necessary.

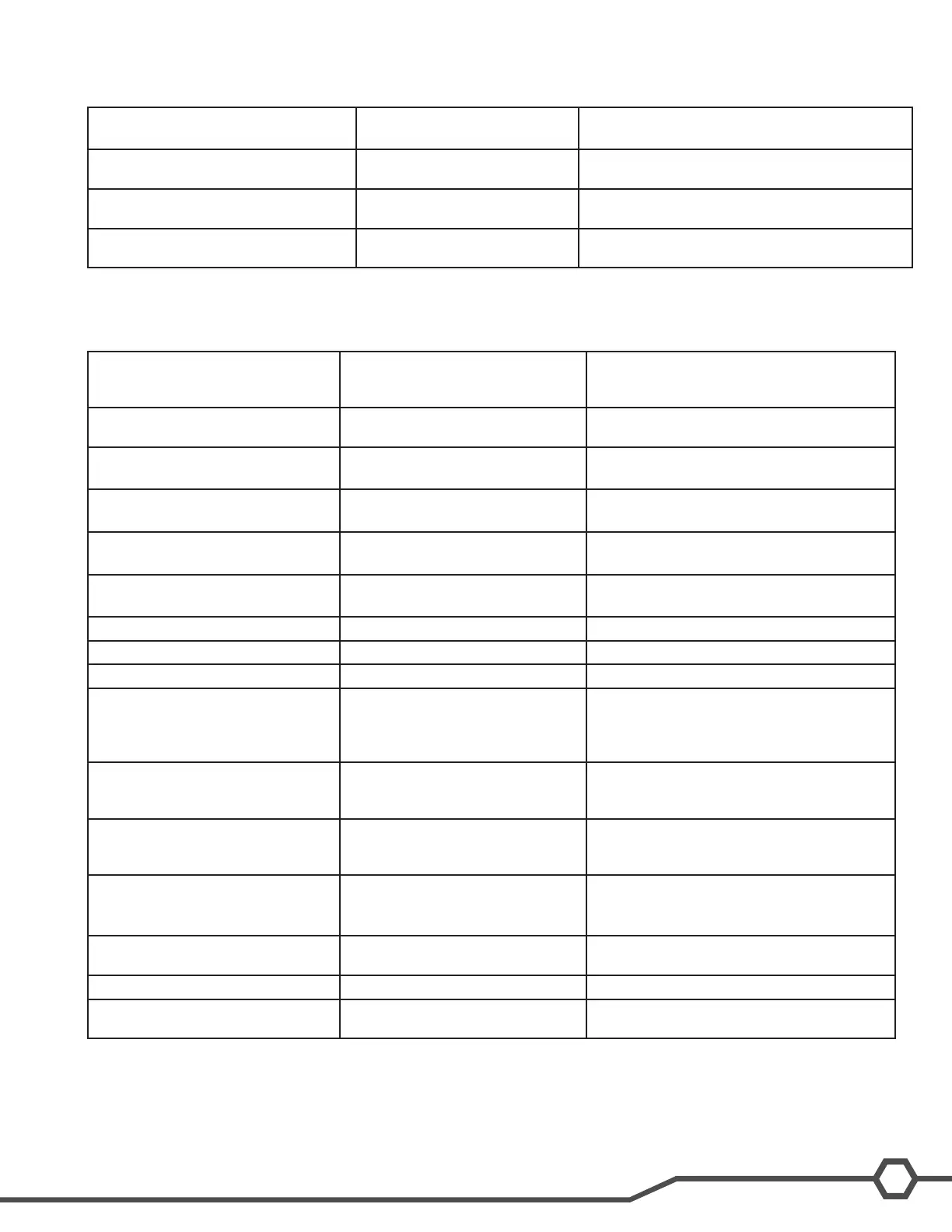

Troubleshooting the Brewing Circuit

breW cycle Will not start 1. display’s error Message

Brewer has shut down due to malfunction.

See Service Fault Messages section in

this manual

“ “ 2. no Water

Water lines and valves to the brewer must

be open

“ “ 3. no poWer or incorrect

voltage to the breWer

Check for voltage across the terminals at

the terminal block.

“ “ 4. on/off sWitch not in the

“on” position

The indicator lamp must be lit

“ “ 5. loW Water teMperature

(breW lockout is enabled)

Allow brewer to heat until ready, or dis-

able the brew lockout feature.

“ “ 6. Water not touching refill

probe inside tank

Watermustbeincontactwithrellprobe

before brew cycle will start.

“ “ 7. MeMbrane sWitch

Check/replace

“ “ 8. dispense valve

Check/replace

“ “ 9. control board

Check/replace

consistently loW beverage

level in the dispenser or bev-

erage overfloWs dispenser

1. breW voluMe

NOTE: Volume adjustments

must be made with sprayhead

installed.

Calibrate Sprayhead

“ “ 2. liMe build up

Inspect the dispense valve and sprayhead

for excessive lime deposits. Delime as

required.

“ “ 3. dispense valve

Remove dispense valve and clear any

obstructions. Rebuild or replace valve if

necessary.

breW cycle starts, then

aborts and returns to Main

screen after 20 seconds

1. level probes shorted

Ensure mylar shield(s) are installed on top

cover

dripping froM sprayhead 1. liMe build up

Inspect the tank assembly for excessive

lime deposits. Delime as required.

2. dispense valve

Check/replace

Weak beverage 1. sprayhead

A clean sprayhead must be used for

proper extraction.

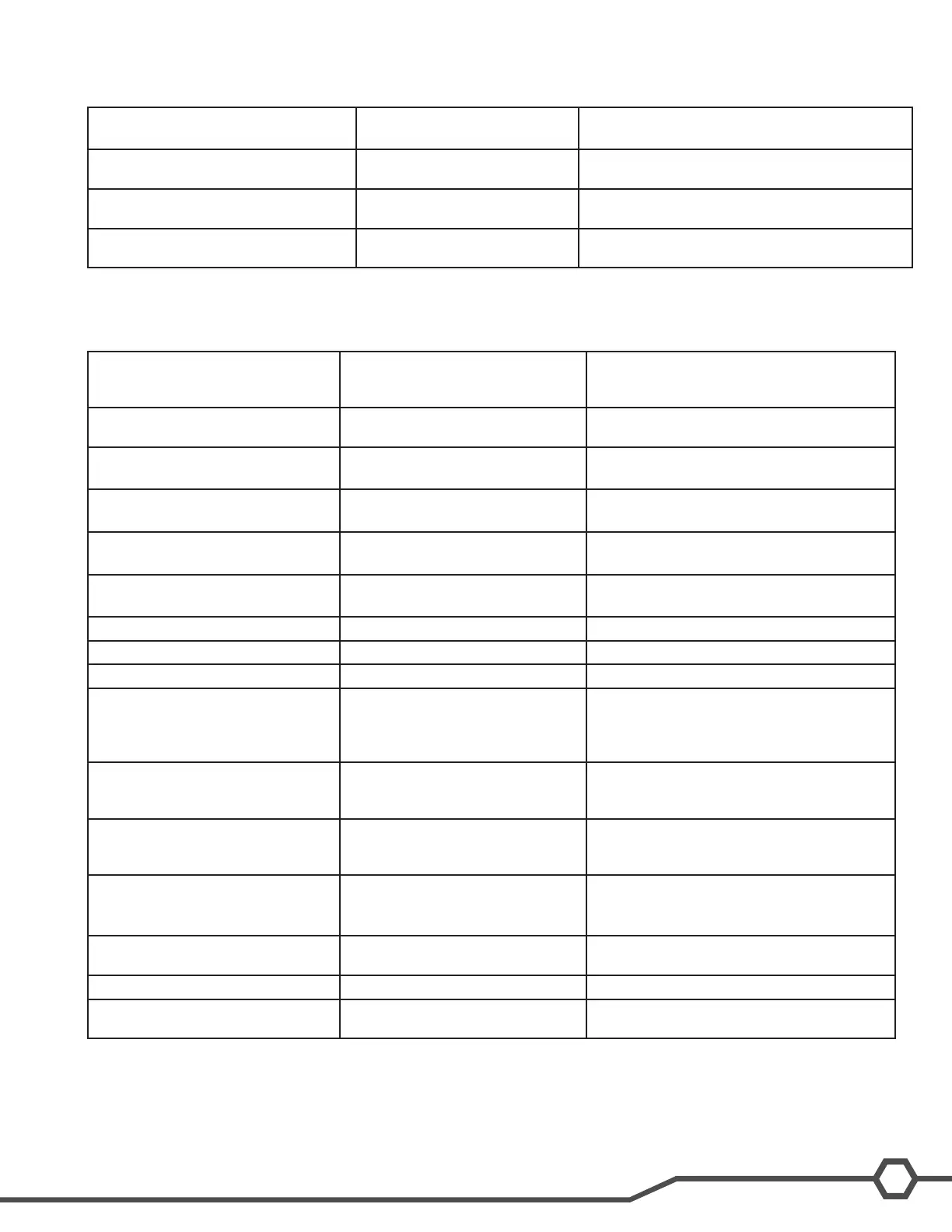

Heating Circuit (cont.)

probleM probable cause reMedy

probleM probable cause reMedy

Loading...

Loading...