25

Installation

8.3.1 Installation of the valve body

Welded bodies

→ Weldvalvebodyinpipelinesystem.

Other body versions

→ Connectbodytopipeline.

8.3.2 Install actuator (welded body)

Seal

Fig. 18: Seal

→ Checkthesealandifrequired,replaceit.

WARNING!

Danger if incorrect lubricants used!

Unsuitablelubricantmaycontaminatethemedium.Inoxygen

applicationsthereisariskofanexplosion!

▶ Inspecicapplications,e.g.oxygenoranalysisapplications,

useappropriatelyauthorizedlubricantsonly.

→ Greasenipplethreadbeforere-installingtheactuator(e.g.

withKlüberpasteUH196-402fromKlüber).

NOTE!

Damage to the seat seal or the seat contour!

▶ Wheninstallingtheactuator,ensurethatthevalveisinopen

position.

→ ControlfunctionApressurizethepilotairport1withcom-

pressedair(5bar):valveopens.

→ Screwactuatorintothevalvebody.

Observetighteningtorque(see“Tab.16”).

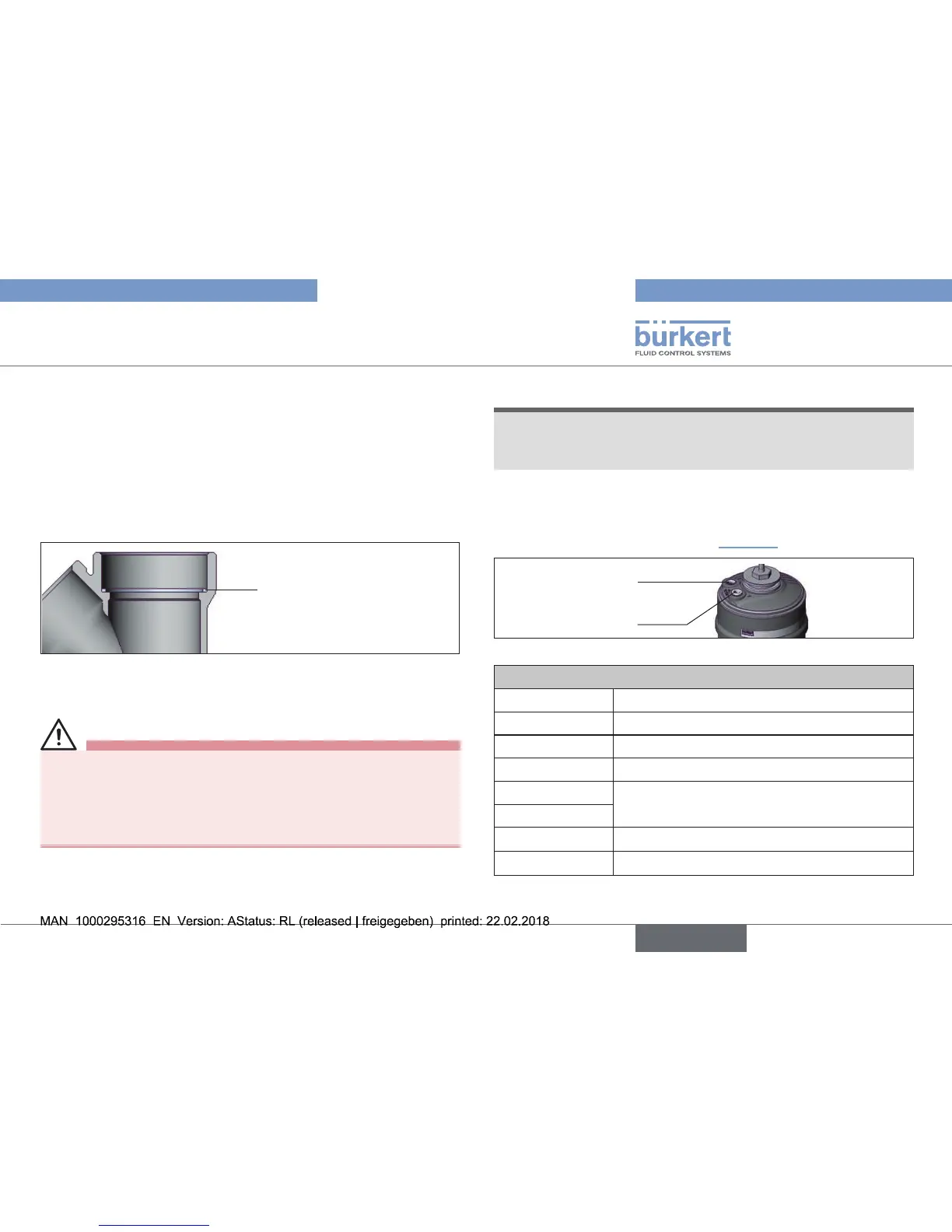

1

2

Pilotairport

Fig. 19: Connections

Tightening torques of valve body / nipples

DN Tightening torque [Nm]

15 45 ±3

20 50 ±3

25 60 ±3

32

65 ±3

40

50 70 ±3

65 100 ±3

Tab. 16: Tightening torques of valve body / nipples

Loading...

Loading...