39

Maintenance, cleaning

Install the actuator (with control unit) on the valve body

→ Checkthesealandifrequired,replaceit.

WARNING!

Danger if incorrect lubricants used!

Unsuitablelubricantmaycontaminatethemedium.Inoxygen

applicationsthereisariskofanexplosion!

▶ Inspecicapplications,e.g.oxygenoranalysisapplications,

useappropriatelyauthorisedlubricantsonly.

→ Greasenipplethreadbeforere-installingtheactuator(e.g.

withKlüberpasteUH196-402fromKlüber).

NOTE!

Damage to the seat seal or the seat contour!

▶ Wheninstallingtheactuator,ensurethatthevalveisinopen

position.

→ Control function A:

Without unit control:pressurizethepilotairport1withcom-

pressedair(5bar):valveopens.

With unit control:openthevalveaccordingtotheoperating

instructionsforthecontrolunit.

→ Screwactuatorintothevalvebody.

Observetighteningtorque(see“Tab.20”).

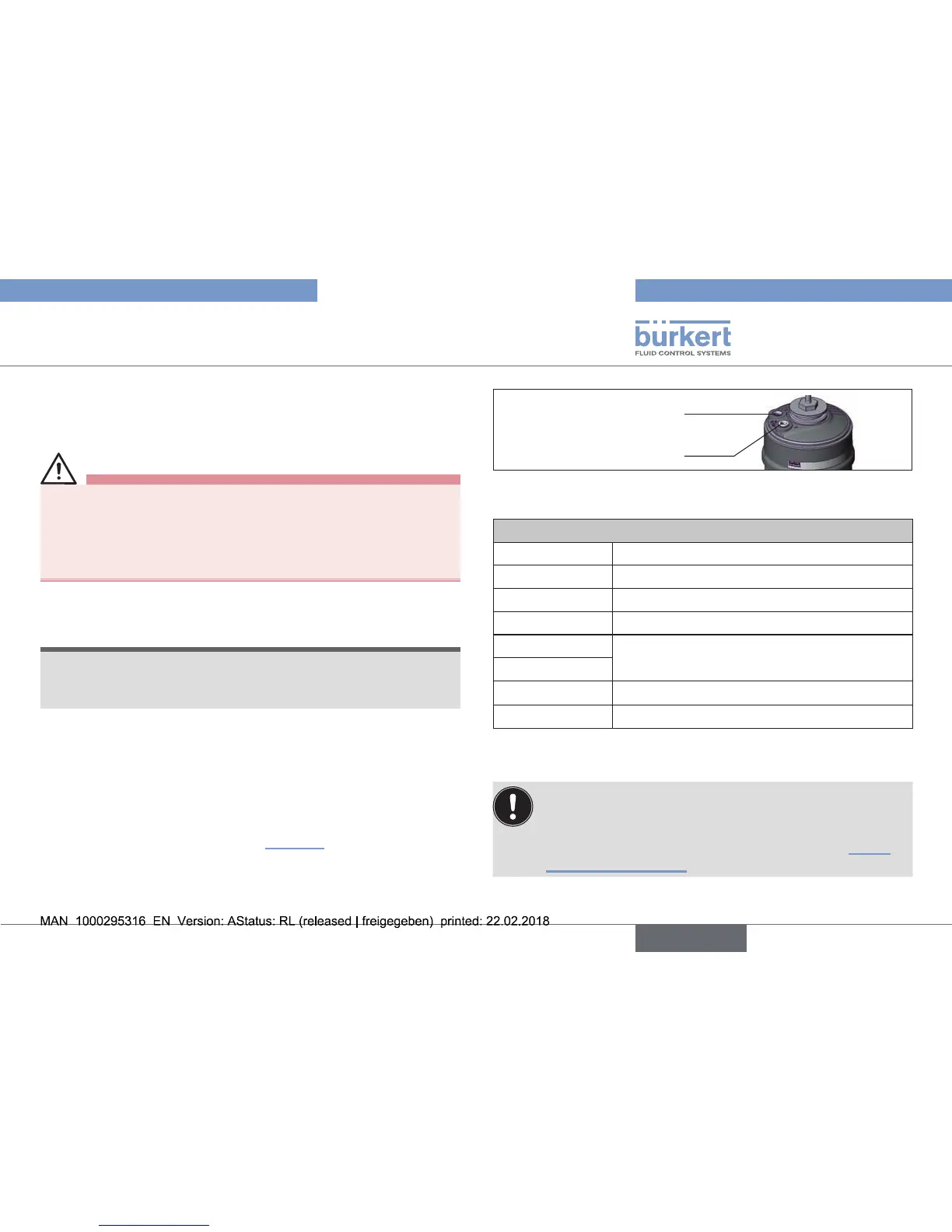

1

2

Pilotairport

Fig. 36: Connections

Tightening torques of valve body / nipples

DN Tightening torques [Nm]

15 45 ±3

20 50 ±3

25 60 ±3

32

65 ±3

40

50 70 ±3

65 100 ±3

Tab. 20: Tightening torques of valve body / nipples

Ifthepositionofthepilotairportsforinstallationofthe

hosesisunfavorable,thesecanbealignedsteplesslyby

rotatingtheactuatorthrough360°.

Theprocedureisdescribedinthechapterentitled“8.3.4

Rotatingtheactuator”.

Loading...

Loading...