32

Maintenance, cleaning

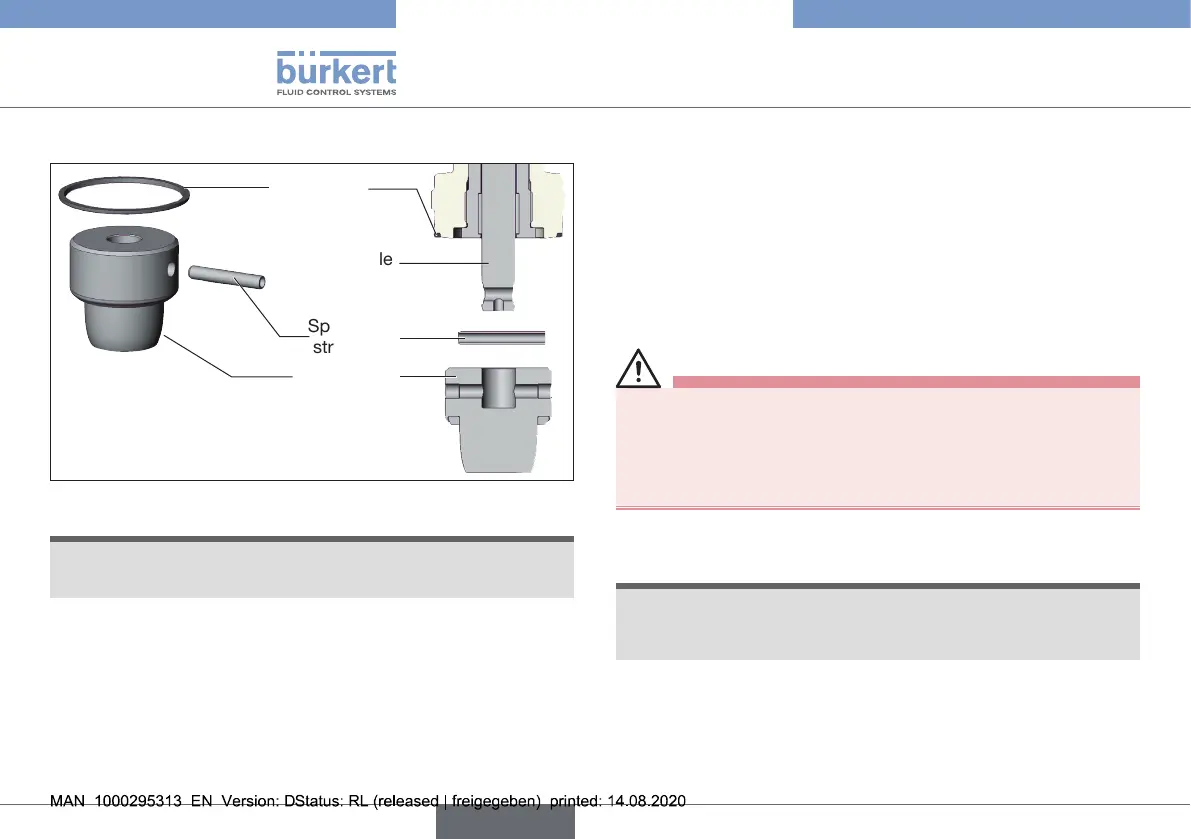

Change control cone set

Spindle

Spring-type

straightpin

Control cone

Seal

Fig.19: Replacing the control cone set

NOTE!

Important for impeccable and stable device function.

Thesealsurfaceofthecontrolconemustnotbedamaged.

Procedure:

→ Knockoutspring-typestraightpinusingasuitablepinpunch.

Pin punch ø4mm

,withspindlediameter10mm

Pin punch ø5mm,

withspindlediameter14mm

→ Removecontrolcone.

→ Placenewcontrolconeonthespindle.

→ Alignboreholesinthecontrolconeandspindle.

→ Supportcontrolconeonthecylindricalpartusingaprismor

somethingsimilar.

→ Setupthespring-typestraightpinandcarefullyhammeritin.

→ Centrethespring-typestraightpinwiththespindleaxis.

Install actuator (with control unit) on the valve body

→ Replacethesealifnecessary.

WARNING!

Risk due to incorrect lubricants.

Unsuitablelubricantmaycontaminatethemedium.Thereisa

riskofexplosioninoxygenapplications.

▶ Forspecicapplications,e.g.oxygenoranalysisapplica-

tions,useapprovedlubricantsonly.

→ Beforere-installation,greasenipplethreadoftheactuator

(e.g.usingKlüberpasteUH196-402fromKlüber).

NOTE!

Damage to the valve seat seal or seat contour.

▶ Wheninstallingtheactuator,thevalvemustbeintheopen

position.

→ For control function A

Without control unit:pressurisepilotairport1withcom-

pressedair(5bar).Valveopens.

With control unit:openthevalveinaccordancewiththeoper-

atinginstructionsofthecontrolunit.

Type2301

English

Loading...

Loading...