33

Maintenance, cleaning

→ Screwactuatorintothevalvebody.Observetighteningtorque

(see“Tab.1:Actuatorsizes”).

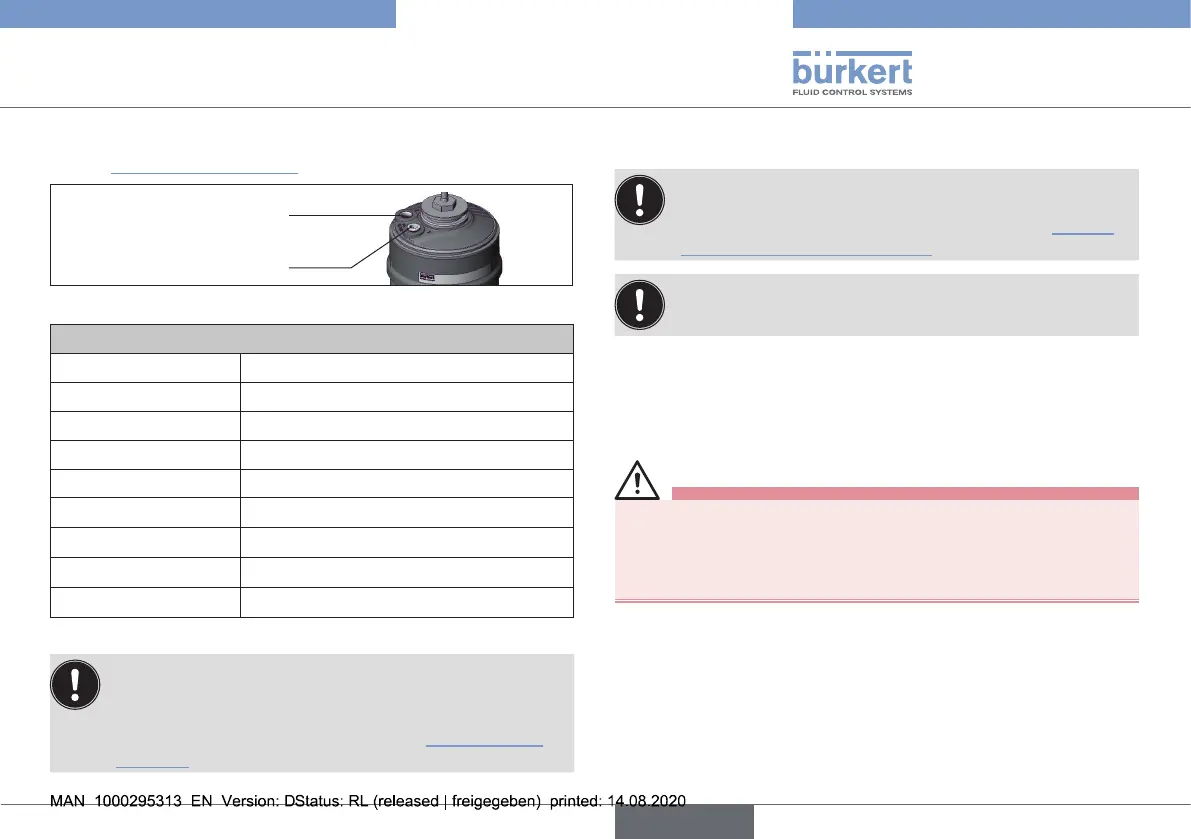

1

2

Pilot air port

Pilot air port

Fig.20: Ports

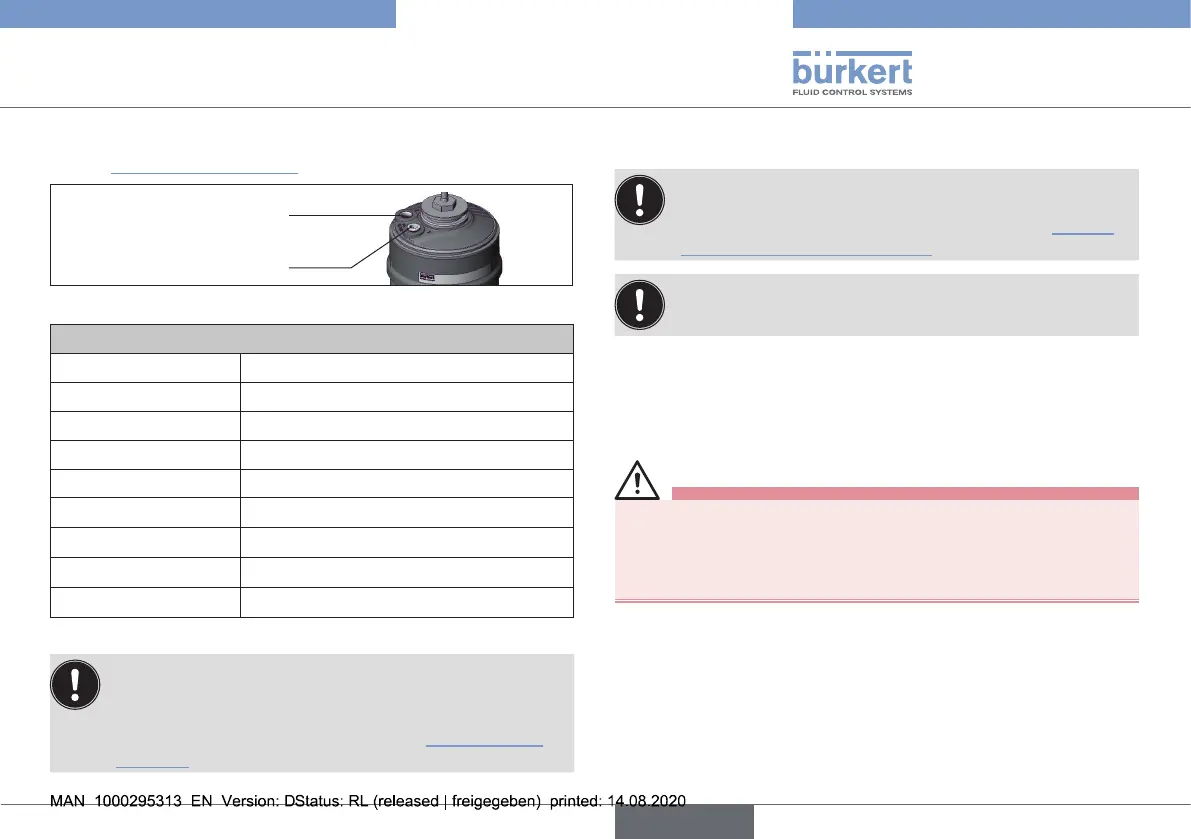

Tightening torques valve body/nipple

DN Tightening torque [Nm]

10/15 45±3

20

50±3

25 60±3

32,40 65±3

50 70±3

65 100±3

80 120±5

100 150±5

Tab.12: Tighteningtorquesvalvebody/nipple

If the position of the pilot air ports is unfavourable for

installingthehoses,thesecanbeseamlesslyalignedby

rotatingtheactuatorby360°.

Theprocedureisdescribedinchapter“8.3.4 Turning

actuator”.

10.3.2 Replacing the valve seat set

Theactuatormustbeuninstalledwhenreplacingthe

valve seat.

Thenecessarystepsaredescribedinchapter“10.3.1

Replacingthecontrolconeset”.

WheninstallingavalveseatwithanotherDN,theidenti-

cationnumberoftheglobecontrolvalvechanges.

Thevalveseatsetconsistsof

• Valve seat

•

Graphiteseal

• O-ring(dependingon

variant)

• Lubricant

DANGER!

Risk of injury from discharge of pressure and escaping medium.

Dismantlingadevicewhichisunderpressureishazardousdue

toasuddendischargeofpressureorescapingmedium.

▶ Beforedisassembly,shutothepressureandventalllines.

Type2301

English

Loading...

Loading...