34

Maintenance, cleaning

WARNING!

Risk of injury due to improper operation.

Failuretoobservethetighteningtorquevalueisdangerousdue

totheriskofdamagetothedevice.

▶ Onlyperformthereplacementwithspecialassemblytools

(forordernumbersseechapter“12.2Assemblytools”).

▶ Observethetighteningtorque(see“Tab.12:Tightening

torquesvalvebody/nipple” and “Tab.13:Tighteningtorques

valveseatassembly”).

Procedure:

→ Replacethevalveseatasdescribedbelowwhentheactuator

isremoved.

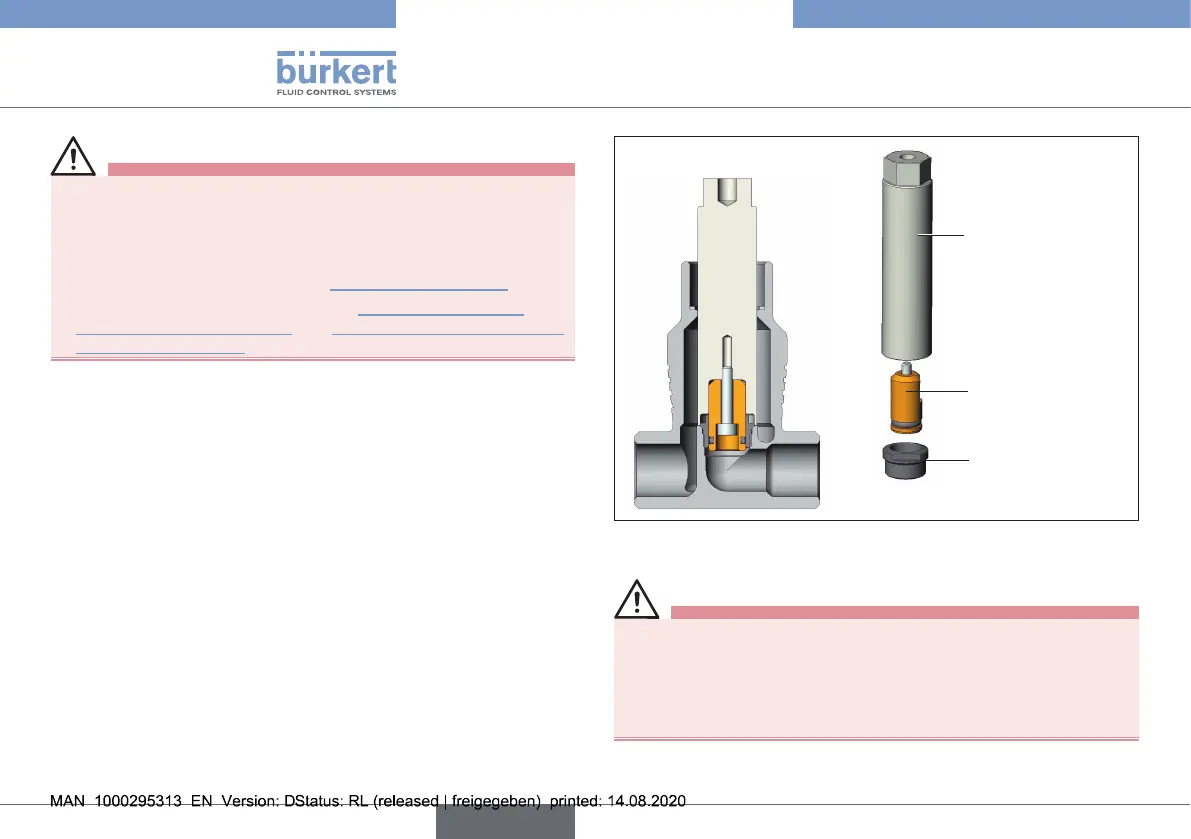

Replacing valve seat

→ Usetheassemblytool(withsuitabletoolattachment)anda

wrenchtounscrewtheoldvalveseat.

→ Cleanthebodythreadandsealsurfacewithcompressedair.

→ Ifnecessary,replacethetoolattachmentintheassemblytool

(dependingontheDNofthenewvalveseat).

→ Attachanewvalveseattotheassemblytool.

Assemblytool

Tool insert

Valve seat

Fig.21: Replacing the valve seat

WARNING!

Risk due to incorrect lubricants.

Unsuitablelubricantmay contaminatethemedium. Thereis a

riskofexplosioninoxygenapplications.

▶ Forspecicapplications,e.g.oxygenoranalysisapplications,

use approved lubricants only.

Type2301

English

Loading...

Loading...