35

Maintenance, cleaning

→ Greasethevalveseatthreadusingasuitablelubricant(e.g.

KlüberpasteUH196-402fromKlüber).

→ Manuallyscrewattachedvalveseatintothevalvebody

thread.

→ Tightenvalveseatusingtorquewrench.Observetightening

torque(see“Tab.13”).

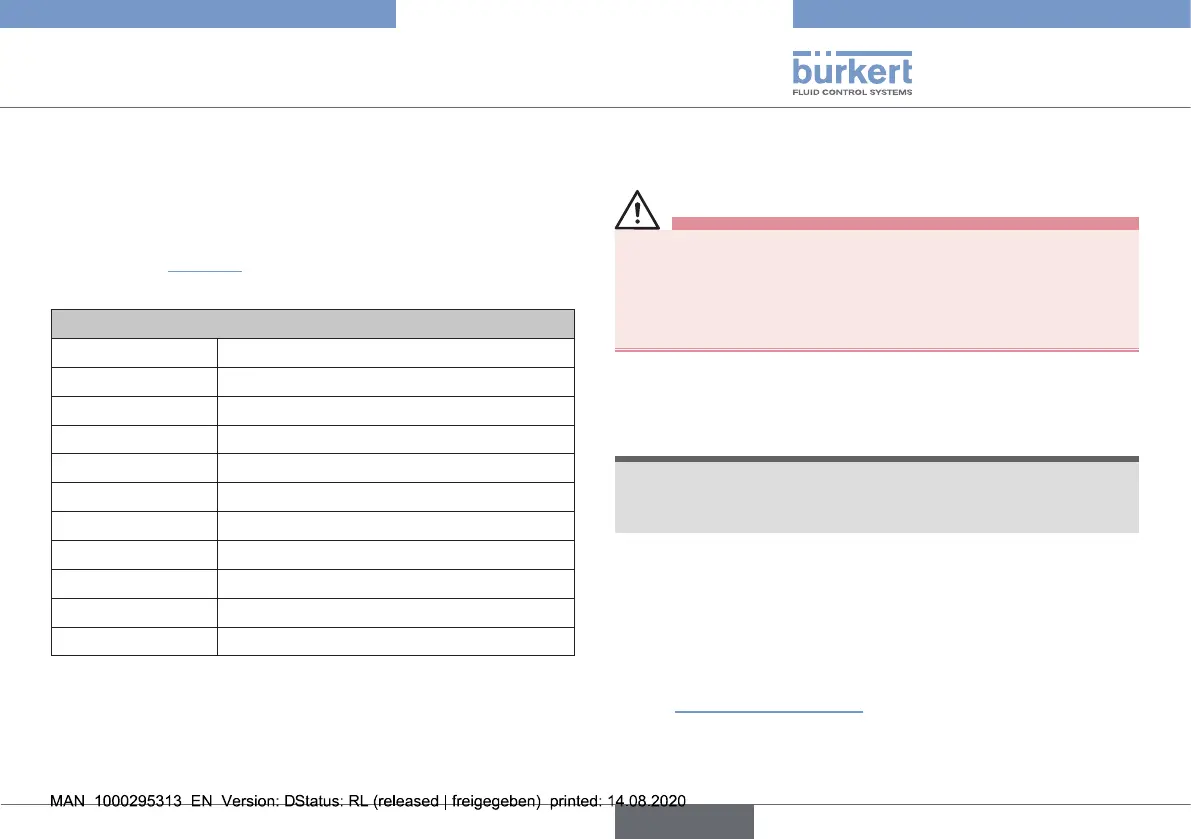

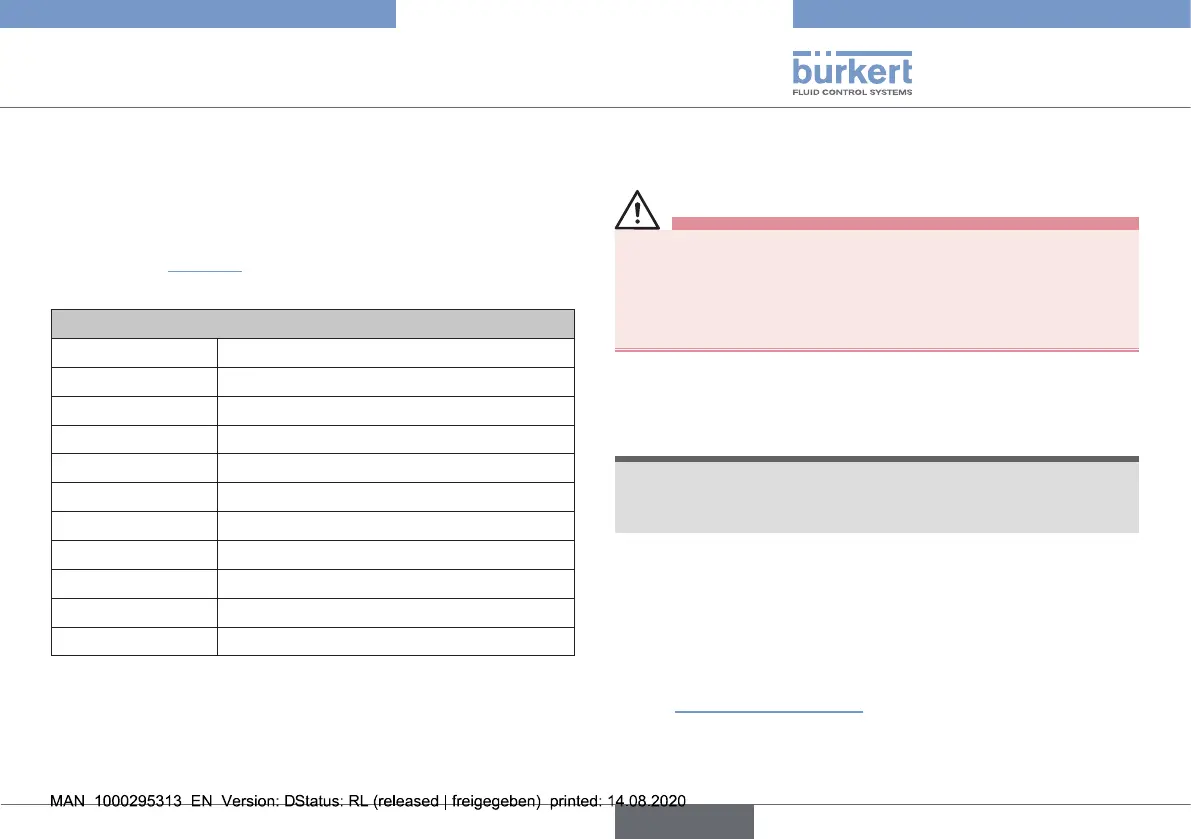

Tightening torques valve seat assembly

Valve seat size Tightening torque [Nm]

Coated valve seat

4–15 20±3

20 28±3

25 40±5

32 65±5

40 85±8

50 120±8

65 150+10

80 180+10

100 220+10

Tab.13: Tighteningtorquesvalveseatassembly

Install actuator (with control unit) on the valve body

→ Replacethesealifnecessary.

WARNING!

Risk due to incorrect lubricants.

Unsuitablelubricantmaycontaminatethemedium.Thereisa

riskofexplosioninoxygenapplications.

▶ Forspecicapplications,e.g.oxygenoranalysisapplica-

tions,useapprovedlubricantsonly.

→ Beforere-installation,greasenipplethreadoftheactuator

(e.g.usingKlüberpasteUH196-402fromKlüber).

NOTE!

Damage to the valve seat seal or seat contour.

▶ Wheninstallingtheactuator,thevalvemustbeintheopen

position.

→ For control function A

Without control unit:pressurisepilotairport1withcom-

pressedair(5bar).Valveopens.

With control unit:Openthevalveinaccordancewiththe

operatinginstructionsofthecontrolunit.

→ Screwactuatorintothevalvebody.Observetighteningtorque

(see“Tab.1:Actuatorsizes”).

Type2301

English

Loading...

Loading...