26

ENG

MPXPRO - + 0300055EN rel. 1.0 30/08/10

4. COMMISSIONING

4.1 Con guration

Once the electrical connections have been completed (see the chapter

on Installation) and the power supply has been connected, the operations

required for commissioning the controller depend on the type of

interface used, however essentially involve setting the so-called initial

con guration parameters. See the guided commissioning procedure.

1. MXOPZKEYYA0 / IROPZKEYA0 ( rmware 1.x) programming key.

MPXPRO can be con gured using programming keys that have

themselves been programmed. In this case, simply plug the key into

the connector. The operation must be performed with the controller

o . After loading the parameters the controller can be started.

2. Commissioning tool software, VPM. This procedure is used to

program and test the operation of the MPXPRO from a PC during

commissioning when starting the system. In particular, this method

is used to:

• set the values, visibility and attributes of all the parameters

(including unit parameter);

• completely program a key;

• during start-up, monitor and manually override all the inputs/

outputs;

• update the rmware.

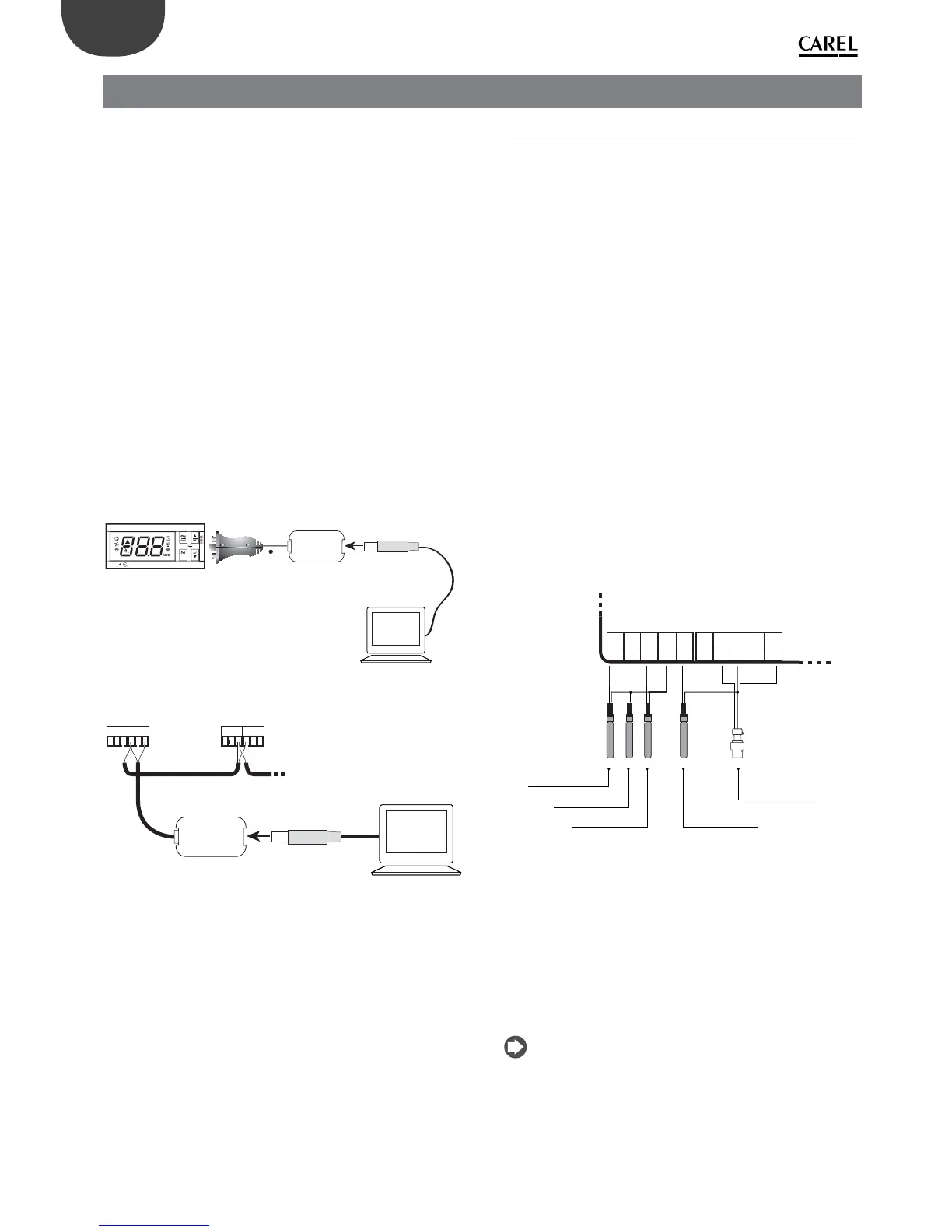

The commissioning tool can be connected from the PC via:

a: a dedicated port available on some user terminals/remote

displays

USB

tLAN

commissioning

cable

Terminal

IR00UGC300

IR00XGC300

IROPZTNL00

USB/tLAN converter

PC

AUX

MPXPRO

Fig. 4.a

b: the RS485 supervisor network

MASTER SLAVE

USB

RS485

tLAN

CVSTDUMOR0

USB/RS485 converter

PC

Fig. 4.b

3. User terminal. When rst started, MPXPRO activates a special

procedure to set the critical parameters for:

• correct communication of the controller with a supervisor and Master/

Slave network;

• management of the electronic valve.

This procedure can be disabled from the key or commissioning tool

(VPM). During this procedure, the device remains in standby and the

functions are disabled (including control and communication via

RS485 or tLAN). The special con guration menu is only displayed on

the user terminal, consequently one needs to be connected if the

function is not disabled (avoiding con icts in the network/LAN or

return of liquid refrigerant to the compressor).

Only after having set all the required parameters can normal

con guration be performed.

4. Remote control. When rst started, this can be used to directly

con gure the critical parameters without needing to activate the

synchronization function (synch button).

4.2 Recommended initial con guration

MPXPRO features highly con gurable inputs and outputs. CAREL in any

case recommends the basic con guration following the default settings

of the parameters. By following this suggestion, the controller can

independently manage the main functions in most applications, without

having to signi cantly modify the settings of the parameters.

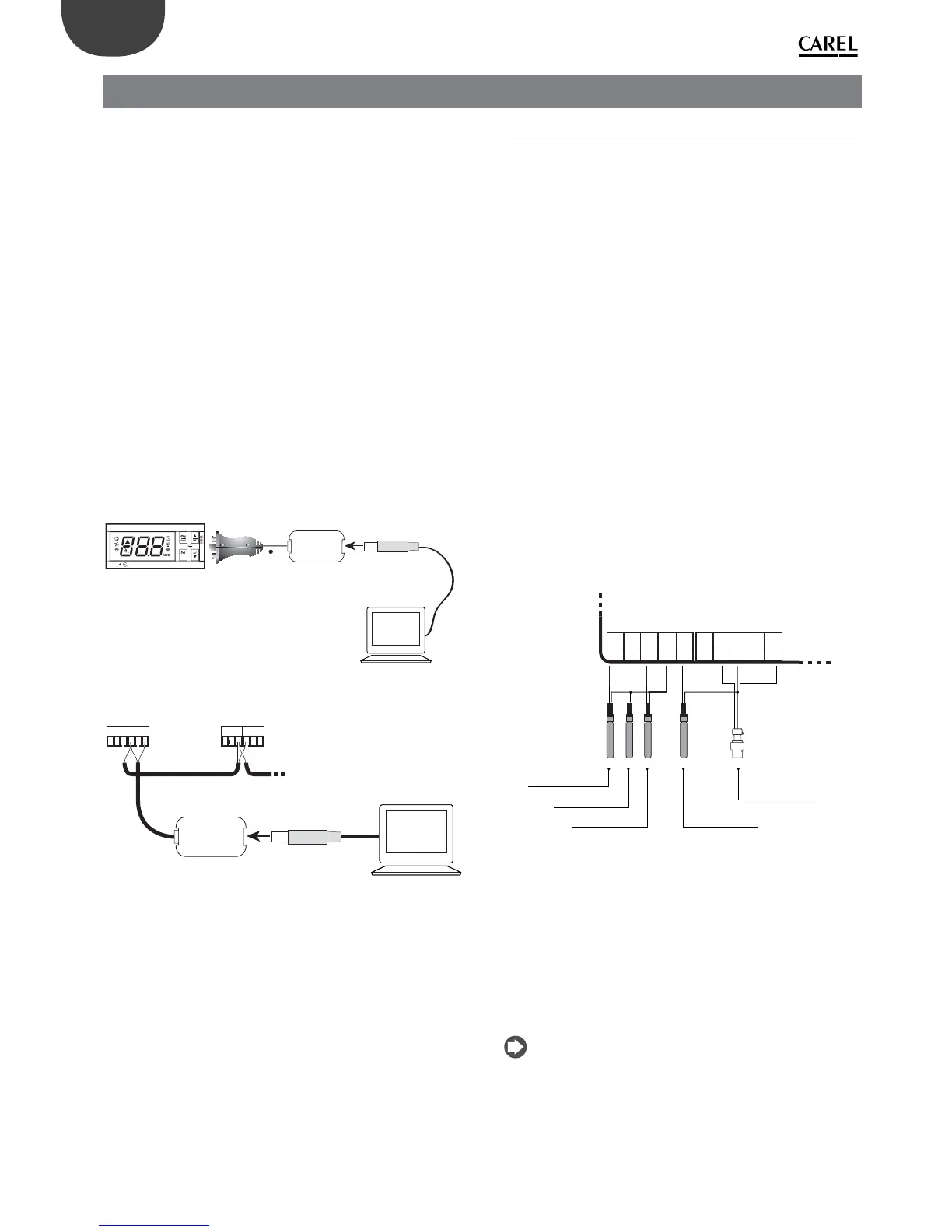

Inputs

The default con guration involves:

Group 1: NTC temperature probes on the showcase:

• S1: NTC outlet probe Sm;

• S2: NTC defrost probe Sd;

• S3: NTC intake probe Sr.

Group 2: superheat control:

• S4/DI1: NTC superheated gas temperature probe on evaporator outlet

(con gured only on models with valve driver included, see parameter

/Fd)

• S5/DI2: input not active;

Group 3: superheat control:

• S6/DI3: ratiometric evaporator pressure probe (con gured only on

models with valve driver included, see advanced parameters /P3, /U6,

/L6, /FE).

Group 4:

• S7: input not active.

Group 5:

• digital input DI5 not active (see parameter A12)

5Vdc

S7/

DI4

GND

S6/

DI3

S5/

DI2

36

S2S1 S3

3537 33

S4/

DI1

GND

3234 30 2931 28

NTC NTC NTC NTC

air o temperature

probe (Sm)

defrost temperature

probe (Sd)

air on temperaure

probe (Sr)

superheated

gas probe (tGS)

saturated evaporation

pressure/temperature

proibe (PEu/tEu)

NTC NTC NTC NTC RATIOMETRIC

Default connections:

Fig. 4.c

Outputs

The default con guration involves:

Relay 1: solenoid valve/compressor (not modi able);

Relay 2: light (see parameter H7);

Relay 3: defrost (not modi able);

Relay 4: evaporator fans (see parameter H1);

Relay 5: alarm (see parameter H5);

PWM 1: anti-sweat heater control, see paragraph 6.3.

PWM 2: evaporator fan speed control, see FAN category parameters.

Note: VPM (Visual Parameter Manager) can be used to modify the

relay mapping.

Loading...

Loading...