34

ENG

MPXPRO - + 0300055EN rel. 1.0 30/08/10

Auxiliary / light serving the Master on the Slaves (H1, H5, H7 = 4/6)

From the Master, the action of the auxiliary output is propagated via tLAN

to the Slaves whose digital output is con gured as H1=4, for the auxiliary

output, and H1=6 for the light output.

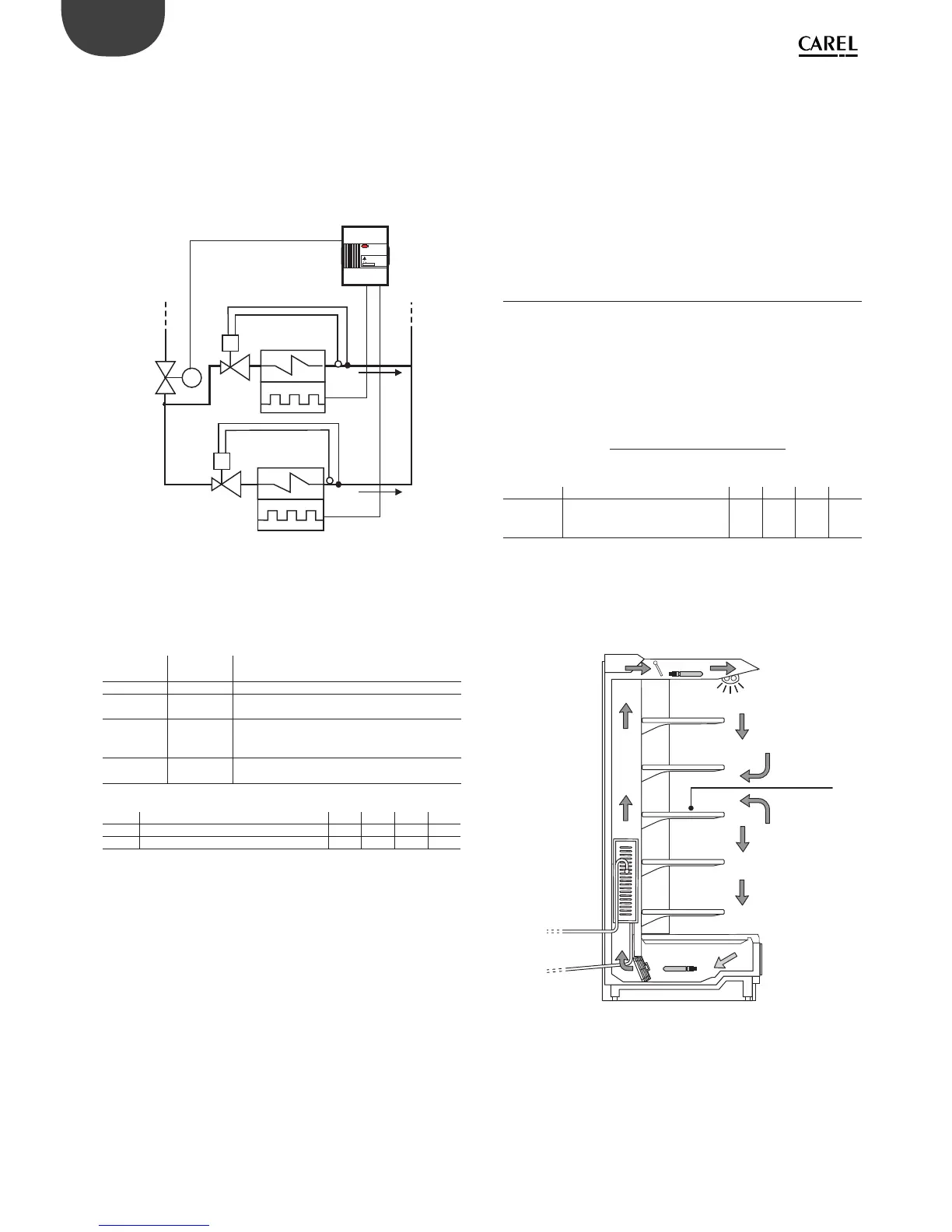

Auxiliary evaporator defrost (not compatible with electronic

expansion valve management)

A heater can be activated to perform a heater defrost on the main and

auxiliary evaporator.

M

MPXPRO

CAREL

!

MASTER

SV

MPXPRO

E

E

T

T

V

V

Fig. 5.d

Key

E Evaporator with electric defrost SV Solenoid valve

V Thermostatic expansion valve

MPXPRO can manage defrosts with one or two outputs and one or two

end defrost probes. The table below summarises the possible cases:

Defrost

outputs

Evaporator

probes

Control

1 1 normal

21

defrost managed on two outputs with reference to

the same evaporator probe

12

defrost managed on the same output with

reference to two evaporator probes (minimum

evaporation temperature)

22

defrost managed independently on the two

evaporator circuits

Tab. 5.k

Par. Description Def Min Max UoM

Sd1 Defrost probe - - - °C/°F

Sd2 Secondary evaporator defrost probe - - - °C/°F

Tab. 5.l

Evaporator fans

This con guration involves using the auxiliary output for the evaporator

fans; the activation/deactivation of the evaporator fans is signalled by the

evaporator fan icon on the display. See paragraphs 5.7 and 6.8.

Anti-sweat heaters

This con guration involves using the auxiliary output to demist the

display cases (control with xed activation, see paragraph 6.3).

Suction and equalizing valve

This con guration involves using the auxiliary output as a suction or

balancing valve for hot gas defrosts. See paragraph 5.6.

Liquid solenoid valve

Available only for R1 AUX4 (modi able only with H13), used to activate

the liquid solenoid valve when ultracap technology is not available or in

applications with thermostatic valves.

NB: the solenoid function in the instrument is always active, even if the

corresponding output is not con gured. The icons and variables on the

supervisor will thus re ect normal operation of the instrument

5.5 Control

Introduction

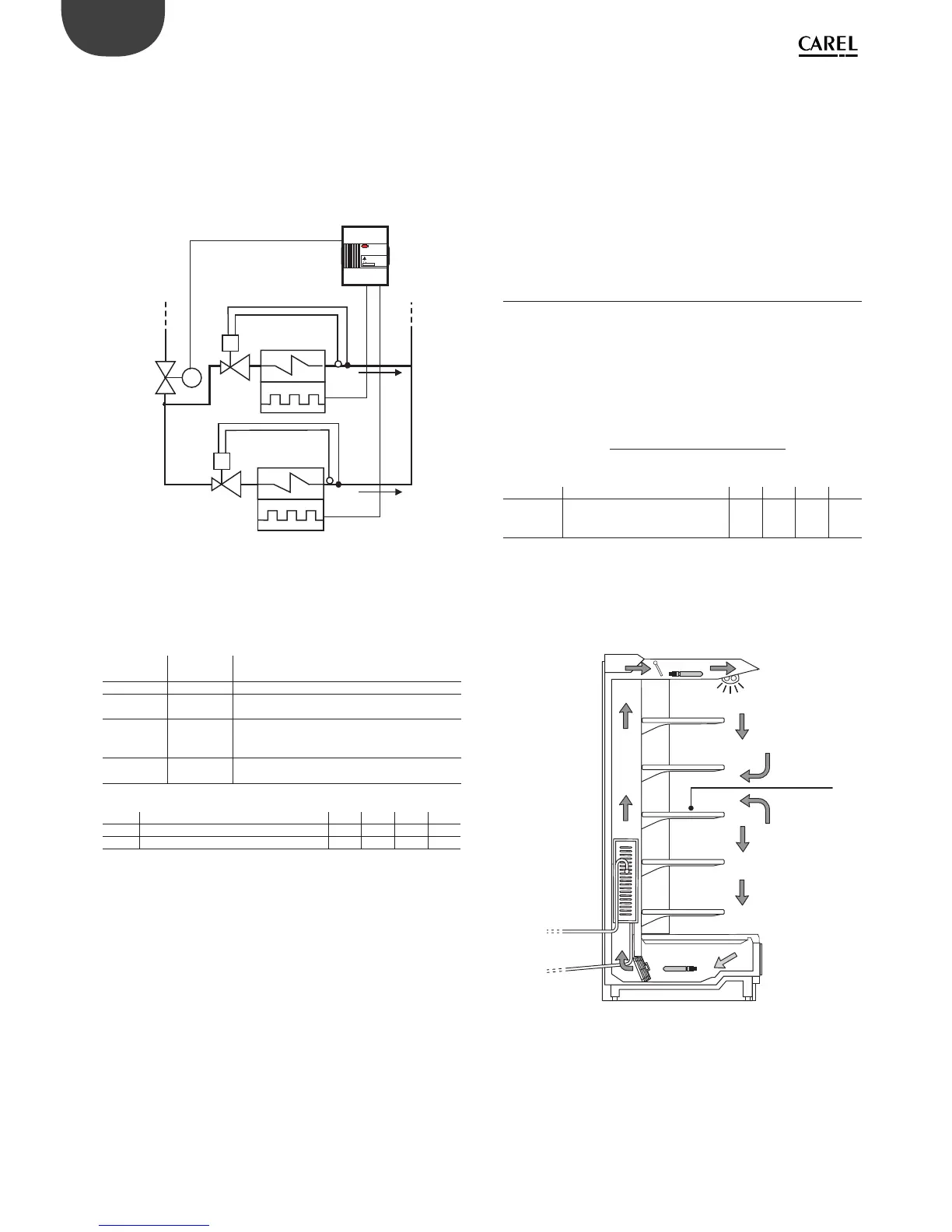

There are various modes for controlling air temperature for the

conservation of foodstu s in cold rooms and showcases. The following

gure shows the position of the intake probe Sr and the outlet probe

Sm. The virtual probe Sv is a weighted average of these two, based on

parameter /4, according to the following formula:

Sv =

Sm toSr t

Par. Description Def Min Max UoM

/4 Virtual probe composition

0 = outlet probe Sm

100 = intake probe Sr

0 0 100 %

Tab. 5.m

For example if /4=50, Sv=(Sm+Sr)/2 represents the estimated value of the

air temperature around the food being cooled.

Example: vertical showcase

DAY

Sm

Sv=(Sm+Sr)/2

Sr

Fig. 5.e

Key

Sm Outlet probe Sv Virtual probe

Sr Intake probe

Loading...

Loading...