52

ENG

MPXPRO - + 0300055EN rel. 1.0 30/08/10

PID control (parameters P4,P5,P6)

The opening of the electronic valve is controlled based on the di erence

between the superheat set point and the actual superheat calculated by

the probes. The speed of variation, the reactivity and the ability to reach

the set point depend on three parameters:

Kp = proportional gain, parameter P4;

Ti = integration time, parameter P5;

Td = derivative time, parameter P6;

The ideal values to be set vary depending on the applications and the

utilities managed, nonetheless default values are proposed that allow

good control in the majority of cases. For further details, refer to classic

PID control theory.

Par. Description Def Min Max UoM

P4 Proportional gain 15.0 0.0 100.0 -

P5 Integration time

0 = function disabled

150 0 900 s

P6 Derivative time

0 = function disabled

5.0 0.0 100.0 s

Tab. 6.i.k

P4: this represents the ampli cation factor. It determines an action that

is directly proportional to the di erence between the set point and the

actual superheat value. It acts on the speed of the valve, in terms of

steps/°C. The valve moves P4 steps for every degree centigrade variation

in the superheat, opening or closing whenever the superheat increases

or decreases respectively. It also acts on the other control factors, and is

valid in both normal control and with all emergency control functions.

High values ==> fast and reactive valve (e.g. 20 for CO

2

- carbon dioxide

applications).

Low values ==> slow and less reactive valve.

P5: this represents the time required by the controller to balance the

di erence between the set point and the actual superheat. It practically

limits the number of steps that the valve completes each second. It is

only valid during normal control, the special functions in fact have their

own integration time.

High values ==> slow and less reactive valve (e.g. 400 for CO

2

- carbon

dioxide applications)

Low values ==> fast and reactive valve

P5 = 0 ==> integral action disabled

P6: this represents the reaction of the valve to variations in the

superheat. It ampli es or reduces variations in the superheat value.

High values ==> fast variations

Low values ==> limited variations

P6 = 0 ==> di erential action disabled

Example. For CO

2

- carbon dioxide applications: P6=5

6.10 Protectors

LowSH Low superheat

To prevent too low superheat values that may cause the return of liquid to

the compressor or system instability (swings), a low superheat threshold

can be de ned, below which a special protection function is activated.

When the superheat falls below the threshold, the system immediately

enters low superheat status and activates a control action, in addition

to normal control, with the aim of closing the electronic valve more

quickly. In practice, the intensity of the system “reaction” is increased. If

the device remains in low superheat status for a certain period, a low

superheat alarm is activated, with the display showing the message ‘LSH’.

The low superheat signal features automatic reset, when the condition

is no longer present or the controller is switched o (standby). When

low superheat status is activated, the local solenoid valve can be forced

closed (parameter P10).

Par. Description Def Min Max UoM

P7 LowSH: low superheat threshold 7.0 -10.0 P3 K

P8 LowSH: integration time

0 = function disabled

15.0 0.0 240.0 s

P9 LowSH: alarm delay

0 = alarm disabled

600 0 999 s

Tab. 6.j.a

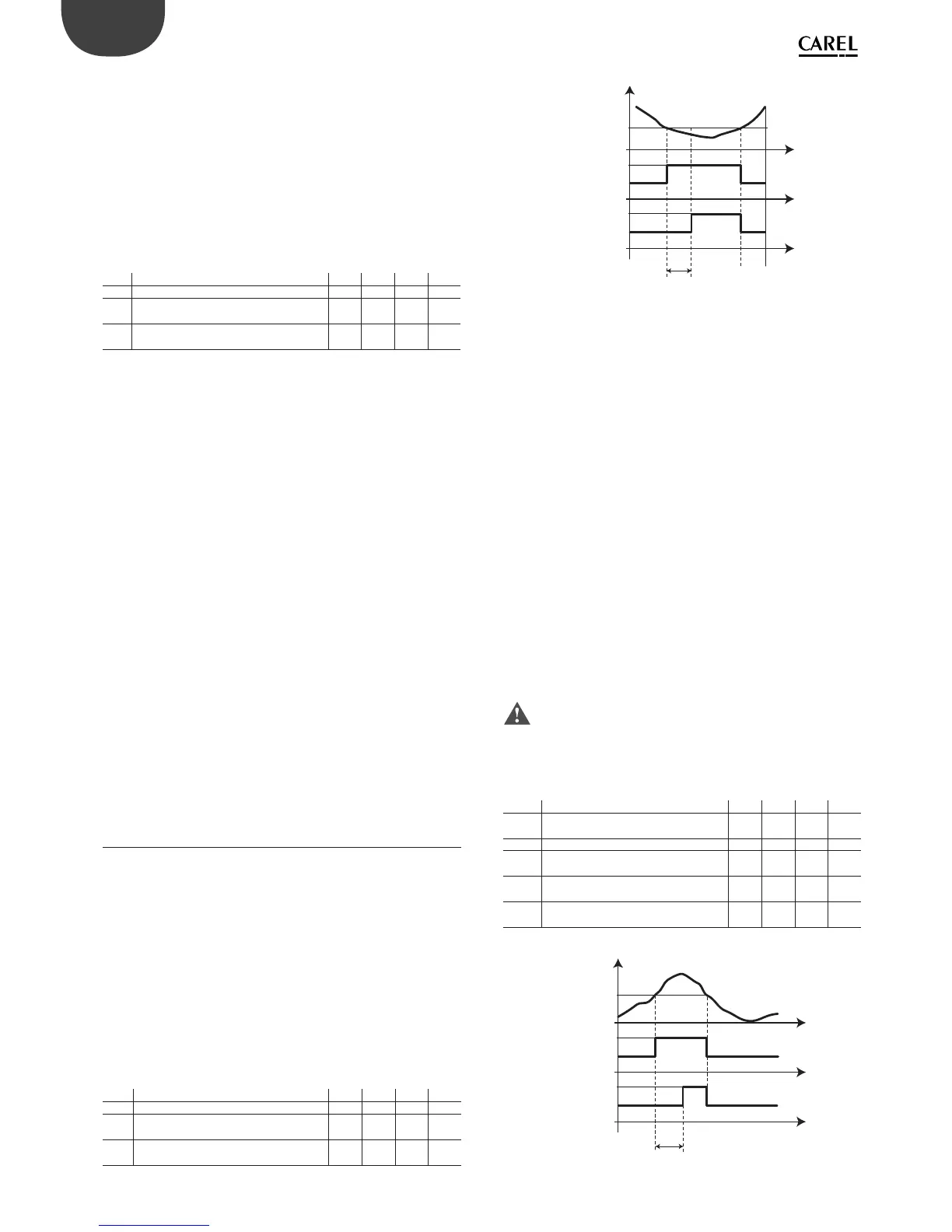

t

B

P9

t

t

ON

P7

LowSH

SH

OFF

ON

ALARM

OFF

Fig. 6.s

Key

SH Superheat P7 LowSH threshold

LowSH Low superheat protection P9 Alarm delay

ALARM Alarm t time

MOP Maximum evaporation pressure

When starting or restarting an installation, the compressors may

not be able to satisfy the simultaneous refrigeration requirements

of all the refrigeration utilities in the installation. This may cause an

excessive increase in the evaporation pressure and consequently the

corresponding saturated temperature. When the evaporation pressure,

expressed in degrees (saturated), rises above the threshold, after a certain

settable time the system enters MOP protection status: PID superheat

control is stopped and the controller starts gradually closing the valve

with an integration action to return the evaporation pressure below

the threshold. The protection function has been designed to allow a

gradual return to normal operating conditions, that is, when the critical

conditions have ended, the controller temporarily operates with a higher

superheat set point until the function is automatically reset.

Important: if this action causes the complete closing of the

electronic valve, the solenoid valve is also closed, even if this is a

network solenoid valve, when enabled. The alarm signal with the

message ‘MOP’ on the display is delayed from the activation of the

protection function and is automatically reset as soon as the saturated

temperature falls below the threshold.

Par. Description Def Min Max UoM

PM1 MOP: saturated evaporation temperature

threshold

50.0 -50.0 50.0 °C/°F

PM2 MOP: integration time 10.0 0.0 240.0 s

PM3 MOP: alarm delay

0 = function disabled

0 0 999 s

PM4 MOP function delay when starting

control

2 0 240 s

PM5 MOP: enable close solenoid valve

(optional)

001-

Tab. 6.j.b

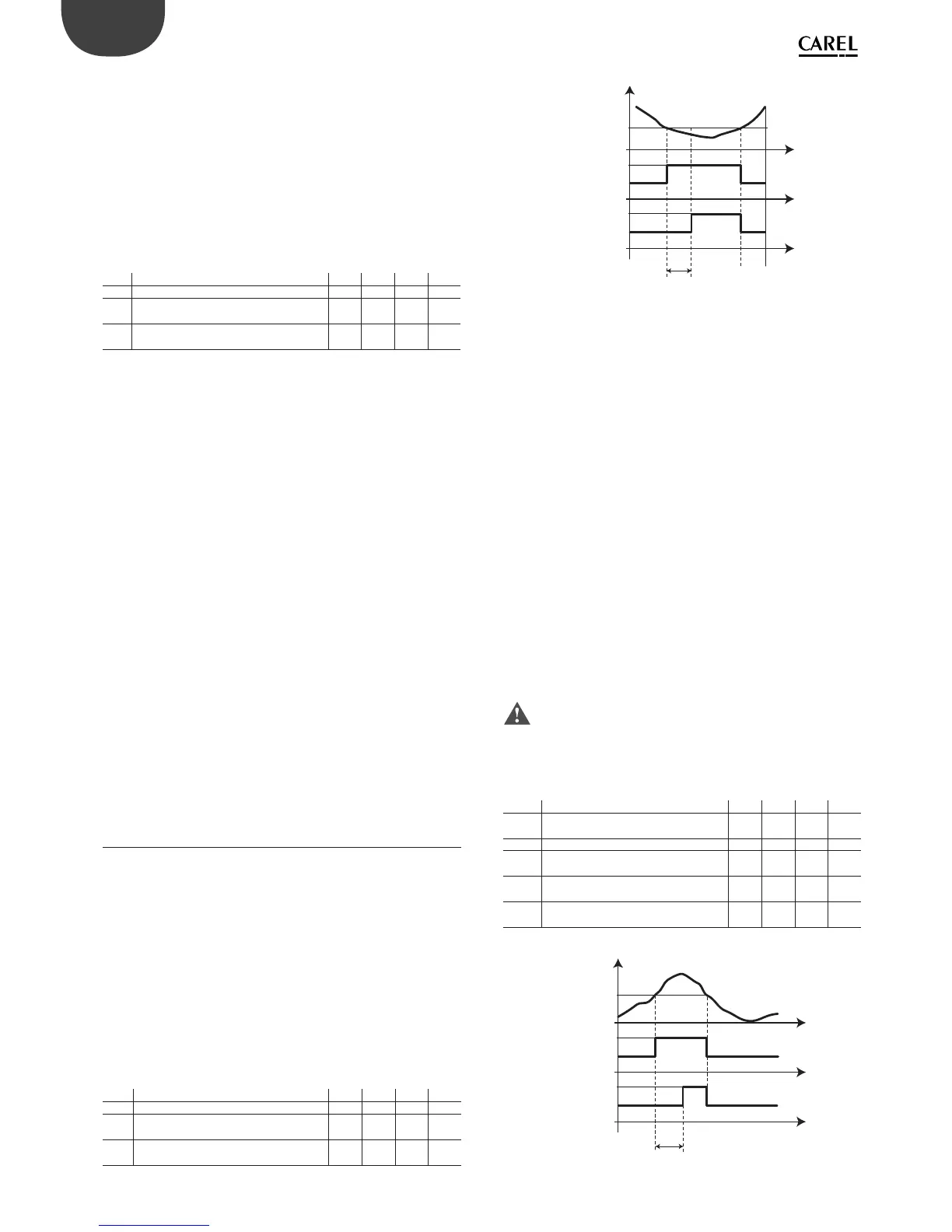

t

PM3

t

t

ON

PM1

MOP

T_EVAP

OFF

ON

ALARM

OFF

Fig. 6.t

Loading...

Loading...