51

ENG

MPXPRO - + 0300055EN rel. 1.1 30/08/10

Valve standby position (parameter PSb)

This indicates the position, as the absolute number of steps, that the

valve must move to after having completely closed, to restore the elastic

operating conditions of the valve spring, by releasing the compression

(for stepper valve only).

Note: the value of this parameter represents the absolute position

of the valve during the closing phase (value read using the

advanced parameter PF on the supervisor).

Par. Description Def Min Max UoM

PSb Valve standby position 0 0 400 step

Tab. 6.i.g

Enable fast update of the valve parameters to

supervisor (parameter Phr)

This is used to enable the fast update to the supervisor of the variables

relating to the electronic expansion valve, such as:

• PF: absolute position in number of steps (stepper valve only);

• SH: superheat;

• PPV: position as a percentage;

• tGS: superheated gas temperature;

• tEu: saturated evaporation temperature;

Useful in the commissioning phase or start-up:

Phr = 0: fast update disabled (update every 30 s);

Phr = 1: fast update enabled (update every 1 s).

Par. Description Def Min Max UoM

Phr Enable fast update of the valve parameters

to supervisor

0 = fast update disabled

001-

Tab. 6.i.h

Important: in the event of power failures, parameter Phr will be

reset to zero.

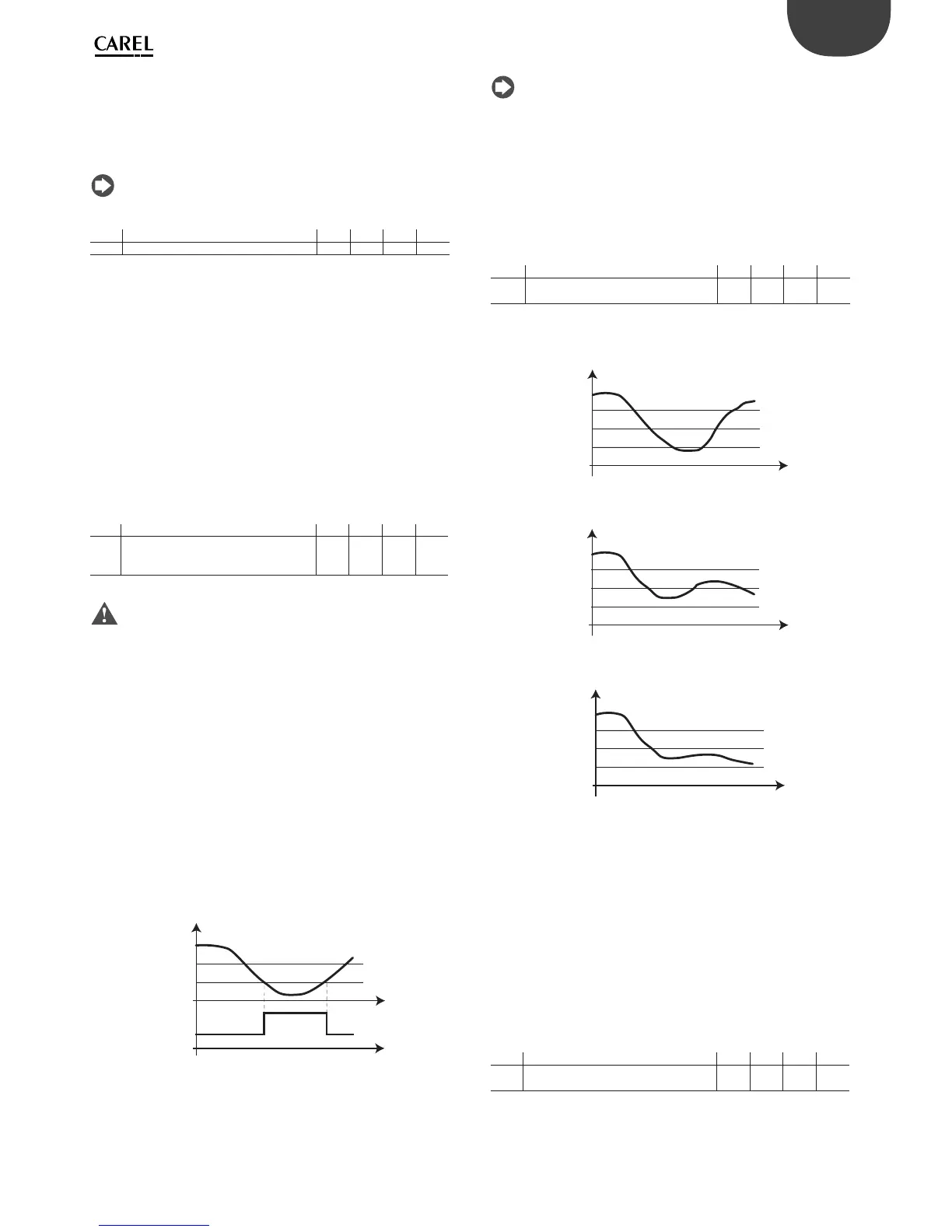

Superheat o set for modulating thermostat

(parameter OSH)

This function is used to reduce or completely eliminate the typical

temperature swings caused by sudden activation/deactivation of the

solenoid valve. The function is activated based on the refrigeration

controller control temperature and a ects the cooling capacity of

the electronic valve. In particular, the function is activated when the

control temperature falls below half of the di erential rd. In this band,

the superheat set point P3 is increased by a term proportional to the

parameter OSH. The e ect of this action is the gradual advanced closing

of the electronic valve, which makes the decrease in temperature inside

of the refrigeration controller slower and more stable. In this way, the

actual temperature of the cabinet can be kept very stable and near the

set point, without ever having to close the solenoid valve, but rather by

simply controlling the ow of refrigerant.

t

t

St+rd

Sreg

St+rd/2

ON

OFF

F

St

Fig. 6.o

Key

Sreg Control probe t time

F

Modulating thermostat

function

Note:

• The action of OSH is weighted, based on the di erence between the

temperature set point and the control temperature. The lower the

di erence, the greater the action of OSH and vice-versa.

• OSH is active in a band at maximum equal to half of the di erential rd

With double thermostat:

• the action of OSH will be determined by the thermostat with the lower

di erence between the set point and the actual temperature;

• the highest contribution is used, Tf= st + rd/2 or Tf2= St2 + rd/2, as

there are two bands.

Par. Description Def Min Max UoM

OSH Superheat o set for modulating

thermostat (0 = function disabled)

0.0 0.0 60.0 K

Tab. 6.i.i

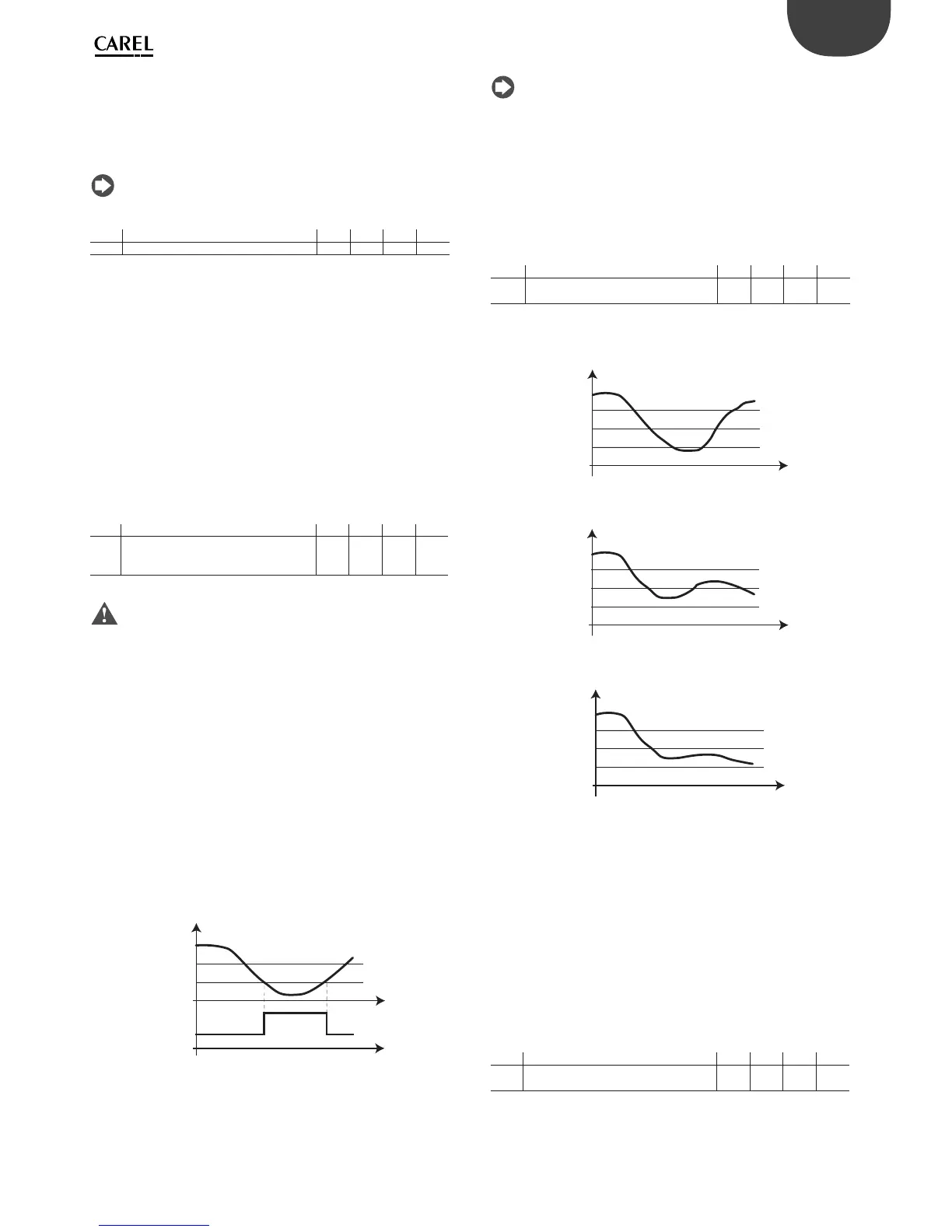

Example

OSH too low

t

St+rd

Sreg

St+rd/2

St

Fig. 6.p

OSH too high

t

St+rd

Sreg

St+rd/2

St

Fig. 6.q

OSH ideale

t

St+rd

Sreg

St+rd/2

St

Fig. 6.r

Key:

Sreg=control probe St=set point

rd = di erential t= time

Support saturated temperature for pressure probe

error (parameter P15)

In the event of a pressure/saturated evaporation temperature probe

error, this represents the constant value used by the device to simulate

the probe reading. In centralised systems, the evaporation pressure is

determined by the compressor rack set point. Once this set point has

been set for P15, control can continue, even if not in perfect conditions,

in emergency situations.

Par. Description Def Min Max UoM

P15 Support saturated temperature for

pressure probe error

-15.0 -50.0 50.0 °C/°F

Tab. 6.i.j

Loading...

Loading...