61

ENG

MPXPRO - + 0300055EN rel. 1.1 30/08/10

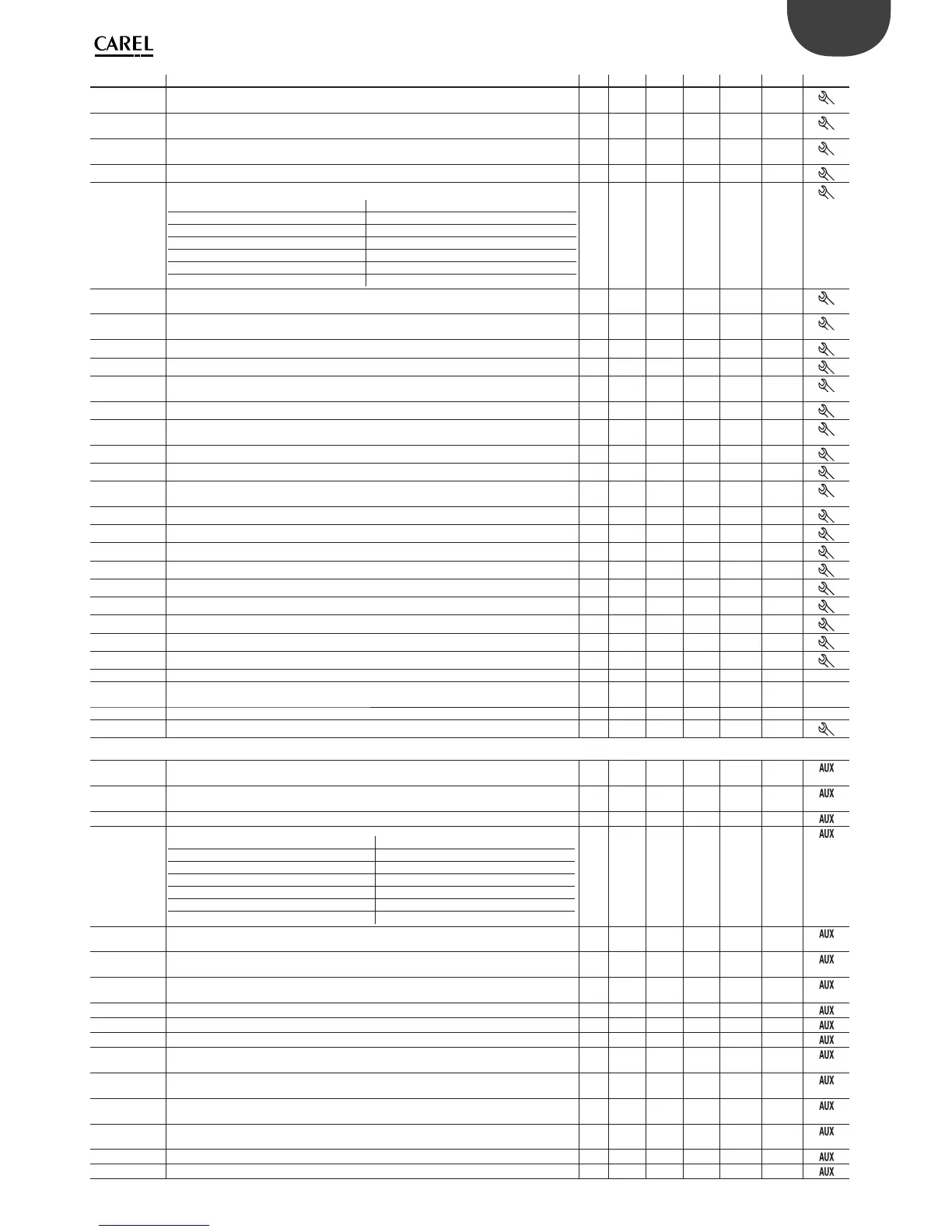

Par. Description Pag. Def Min Max UoM Type Icon

P12 LSA: alarm delay

0 = alarm disabled

55 600 0 999 s A

P13 LSA: alarm di erential (°C)

0 = reset always automatic

55 10.0 0.0 60.0 °C/°F A

P14 Enable valve alarm at end travel (‘blo’)

1 = signal enabled

67 1 0 1 - A

P15 Support saturated temperature for pressure probe error 53 -15.0 -50.0 50.0 °C/°F A

PH Type of refrigerant

1 = R22 8 = R600

2 = R134a 9 = R600a

3 = R404A 10 = R717

4 = R407C 11 = R744

5 = R410A 12 = R728

6 = R507A 13 = R1270

7 = R290 14 = R417A

28-51 3 1 14 - A

OSH Superheat o set for modulating thermostat

0 = function disabled

53 0.0 0.0 60.0 K A

Phr Enable fast update of the valve parameters to supervisor

0 = fast update disabled

52 0 0 1 - A

PM1 MOP: maximum saturated evaporation temperature threshold 54 50.0 -50.0 50.0 °C/°F A

PM2 MOP: integration time 54 10.0 0.0 240.0 s A

PM3 MOP: alarm delay

0 = function disabled

54 0 0 999 s A

PM4 MOP: delay activation of function when starting control 54 2 0 240 s A

PM5 MOP: enable close solenoid valve

0 = closing disabled; 1 = closing enabled

54 0 0 1 - A

PL1 LOP: minimum saturated evaporation temperature threshold 55 -50.0 -50.0 50.0 °C/°F A

PL2 LOP: integration time 55 0.0 0.0 240.0 s A

PL3 LOP: alarm delay

0 = function disabled

55 0 0 240 s A

SH Superheat 40-56 - - - K F

PPU Valve opening percentage 40-56 - - - % F

tGS Superheated gas temperature 40-56 - - - °C/°F F

tEu Saturated evaporation temperature 40-56 - - - °C/°F F

/cE Saturated evaporation temperature calibration 41 0.0 -20.0 20.0 °C/°F A

Po6 PWM expansion valve Ton + To period 56 6 1 20 s A

cP1 Initial valve position when control starts 52 30 0 100 % A

Pdd Initial valve position maintenance time after defrost 52 10 0 30 min A

PSb Valve standby position 52 0 0 400 step A

PF Valve opening steps (supervisor) 56 - 0 - step NV

PMP Enable manual expansion valve positioning

0 = disabled; 1 = enabled

56 0 0 1 - A

PMu Manual valve position 56 - 0 600 step A

Phc Enable high current valve driving 56 0 0 1 - A

CnF (Con guration)

In Type of unit

0 = Slave;1 = Master

28 0 0 1 - C

Sn Number of slaves in the local network

0 = no Slave

28 0 0 5 - C

H0 Serial or Master Slave network address 28 199 0 199 - C

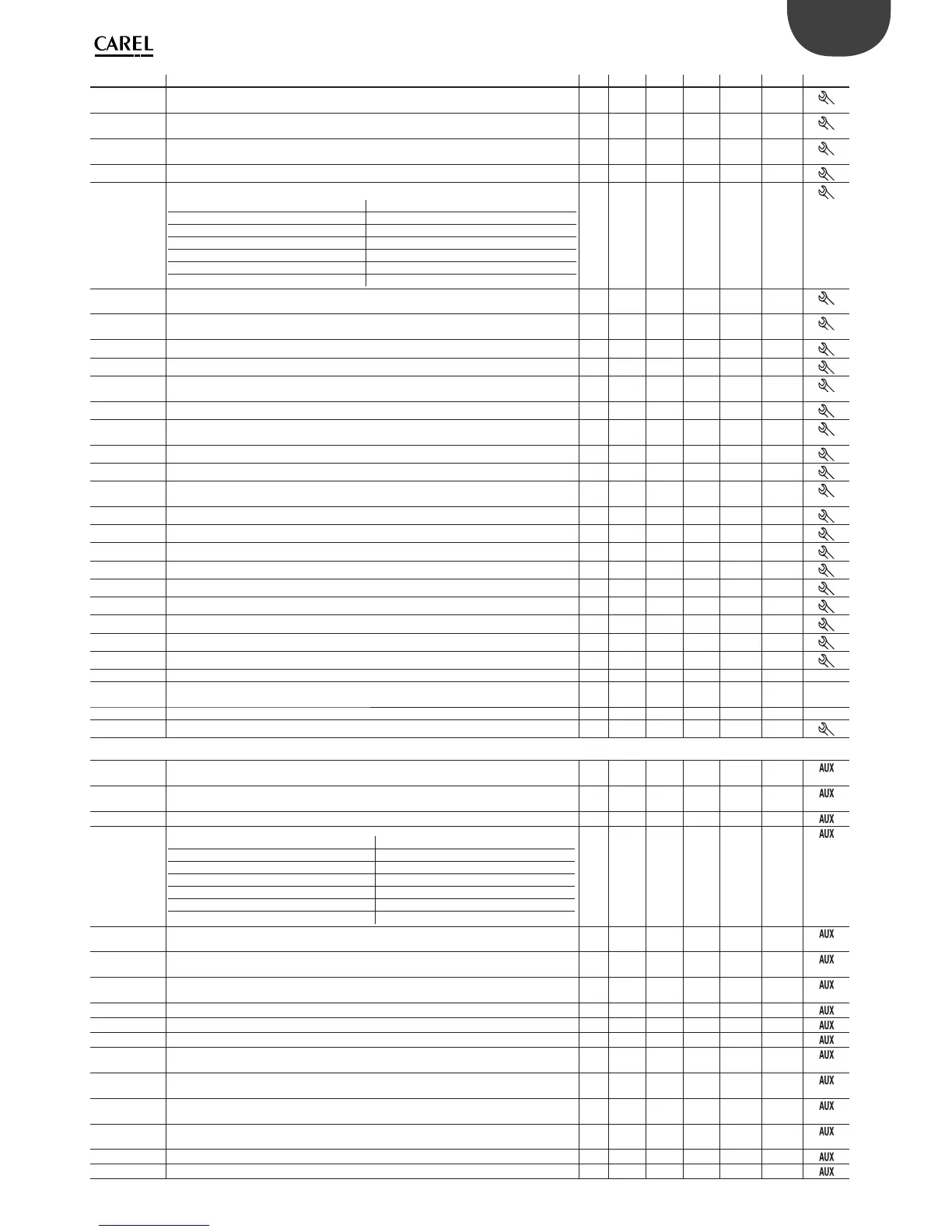

H1 Con gure function of output AUX1

0 = No function 7 = Auxiliary evaporator defrost

1 = Normally de-energized alarm 8 = Evaporator fans

2 = Normally energized alarm 9 = Anti-sweat heaters

3 = Auxiliary 10 = Suction valve

4 = Auxiliary serving MASTER on the Slaves 11 = Equalizing valve.

5 = Light 12 = Solenoid valve.

6 = Light serving the Master on the Slaves

33 8 0 12 - C

H2 Disable keypad and remote control functions

1 = keypad and remote control enabled

57 1 0 5 - A

H3 Remote control enabling code

0 = programming from remote control without code

33 0 0 255 - A

H4 Terminal buzzer (if present)

0 = enabled; 1= disabled

57 0 0 1 - A

H5 Con gure function of output AUX2 see H1 33 2 0 12 - C

H6 Terminal keypad lock con guration 57 0 0 15 - A

H7 Con gure function of output AUX3 see H1 33 5 0 12 - C

H8 Output switched with time bands

0 = Light; 1 = AUX

33 0 0 1 - C

H9 Select function associated with the “aux” button on the user terminal

0 = Light; 1 = AUX.

33 0 0 1 - C

H10 Con gure compressor digital output logic

0 = direct logic; 1 = reverse logic

44 0 0 1 - A

H11 Con gure evaporator fan digital output logic

0 = direct logic; 1 = reverse logic

44 0 0 1 - A

H12 Light sensor threshold 42 25 10 100 lux A

H13 Con gure function of output AUX4 see H1 33 12 0 12 - C

Loading...

Loading...