ENG

“Power+” +0300050EN - rel. 2.3 - 08.06.2012 20

Motor start-up

These parameters optimise the initial start-up phase of the motor and the

relative estimate of the position and the rotor speed. It is recommended to use

the values indicated by CAREL depending on the motors/compressors available.

Mod.

add.

Description Def Min Max U.M. R/W

51 Magnetizing time 100 0 30000 ms R/W

57 Starting current 200

(20.0%)

0 1000

(100.0%)

0.1% R/W

58 Maximum frequency

for starting current

0 0 1000

(100.0%)

0.1%

Motor base

frequency

R/W

Tab. 4.o

Motor control in regenerative functioning mode

It is recommended to use the default values. Typically in the applications with

compressors, the regenerative functioning mode never occurs. For particular

applications, consult CAREL.

Mod.

add.

Description Def Min Max U.M. R/W

53 Regeneration current

limit

1000

(100.0%)

0 2000

(200.0%)

0.1%

Motor rated

current

R/W

54 Overvoltage control

current limit

100

(10.0%)

0 2000

(200.0%)

0.1%

Motor rated

current

R/W

Tab. 4.p

PI parameters for speed regulation

In applications with slow acceleration and deceleration times, as with

compressors, it is recommended to use default values or the values indicated

by CAREL depending on the motors/compressors available. For particular

applications, consult CAREL.

Mod.

add.

Description Def Min Max U.M. R/W

55 Speed loop: Kp 250

(25.0%)

1

(0.1%)

2000

(200.0%)

0.1% R/W

56 Speed loop: Ti 500 1 1000 ms R/W

Tab. 4.q

4.4 C - Asynchronous motor with V/f control

Motor data plate

Frequency/voltage/rated current/power factor

The base frequency is the frequency at which the maximum voltage is applied.

The rated voltage is the maximum voltage applied to the motor. If current

peaks are necessary, the rated current of the motor must be lower enough that

the drive rated current. The Power factor is the rated cos of the motor.

Mod.

add.

Description Def Min Max U.M. R/W

1 Motor base frequency 500

(50.0Hz)

250

(25.0Hz)

5000

(500.0Hz)

0.1Hz R/W

2 Motor base voltage 230/400 25 250/500 V R/W

3 Motor rated current Rated

current (*)

(*) (*) 0.1A R/W

4 Motor power factor

(cos

100

(1.00)

0/50

(0.5)

100

(1.00)

0.01 R/W

Tab. 4.r

(*) Values are model dependent. See chapter 7 “PARAMETERS TABLE”.

Note: see the Appendix for the frequency to the revolution speed

conversion formulas, related to the number of motor poles.

Motor electric data

No parameter has to be set. If Autotuning is performed, the “stator resistance”

parameter is set automatically at the end of the Autotuning procedure on the

basis of the measurements detected, also if its value is not used.

Mod. add. Description Def Min Max U.M. R/W

46 Stator resistance 0 0 38500 m R/W

Tab. 4.s

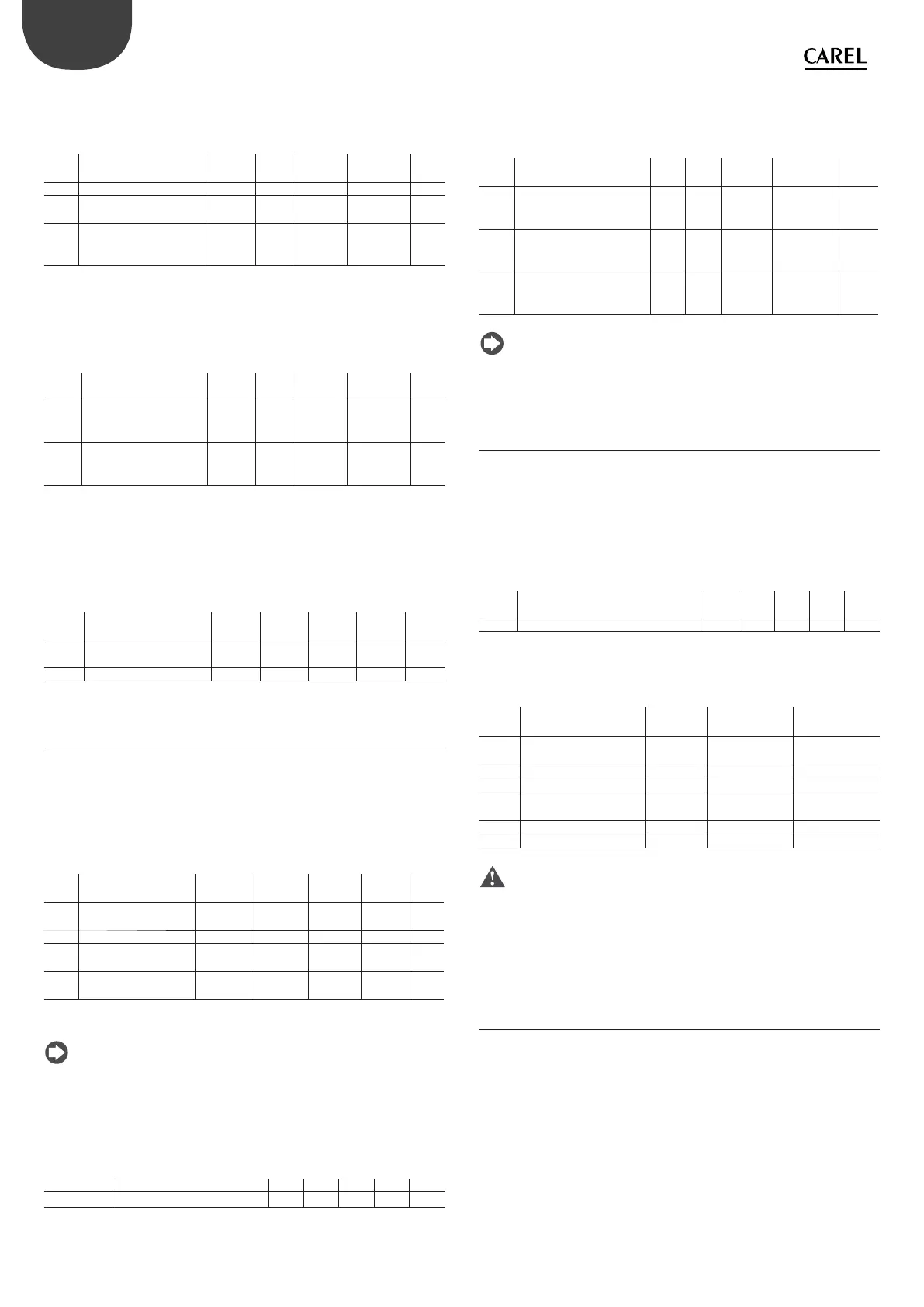

Motor start-up

These parameters optimise the initial start-up phase of the motor by adapting

the V/f feature on the basis of the particular application, in order to improve

performance at low speeds.

Mod.

add.

Description Def Min Max U.M. R/W

35 V/f boost voltage 0 0 250

(25.0%)

0.1%

Motor base

voltage

R/W

36 V/f frequency adjustment 0 0 1000

(100.0%)

0.1%

Motor base

frequency

R/W

37 V/f voltage adjustment 0 0 1000

(100.0%)

0.1%

Motor base

voltage

R/W

Tab. 4.t

Note: In the case of asynchronous motor with V/f control, the parameters

loose meaning for the control of the motor in regenerative functioning mode

and the PI parameters for the speed control.

4.5 Autotuning

Autotuning consists in a measurement cycle, which can last about 1

minute, at the end of which the electric data of the motor are measured

and memorised in the respective parameters. To perform Autotuning, set

the “Autotuning” parameter at 1. At the end, the parameter is automatically

zeroed. The type of measure and the values memorised depend on the type

of motor control selected. See the following tables. If this is unsuccessful,

check the alarm 15. It is therefore necessary to repeat the procedure or search

for the data requested in order to introduce them directly.

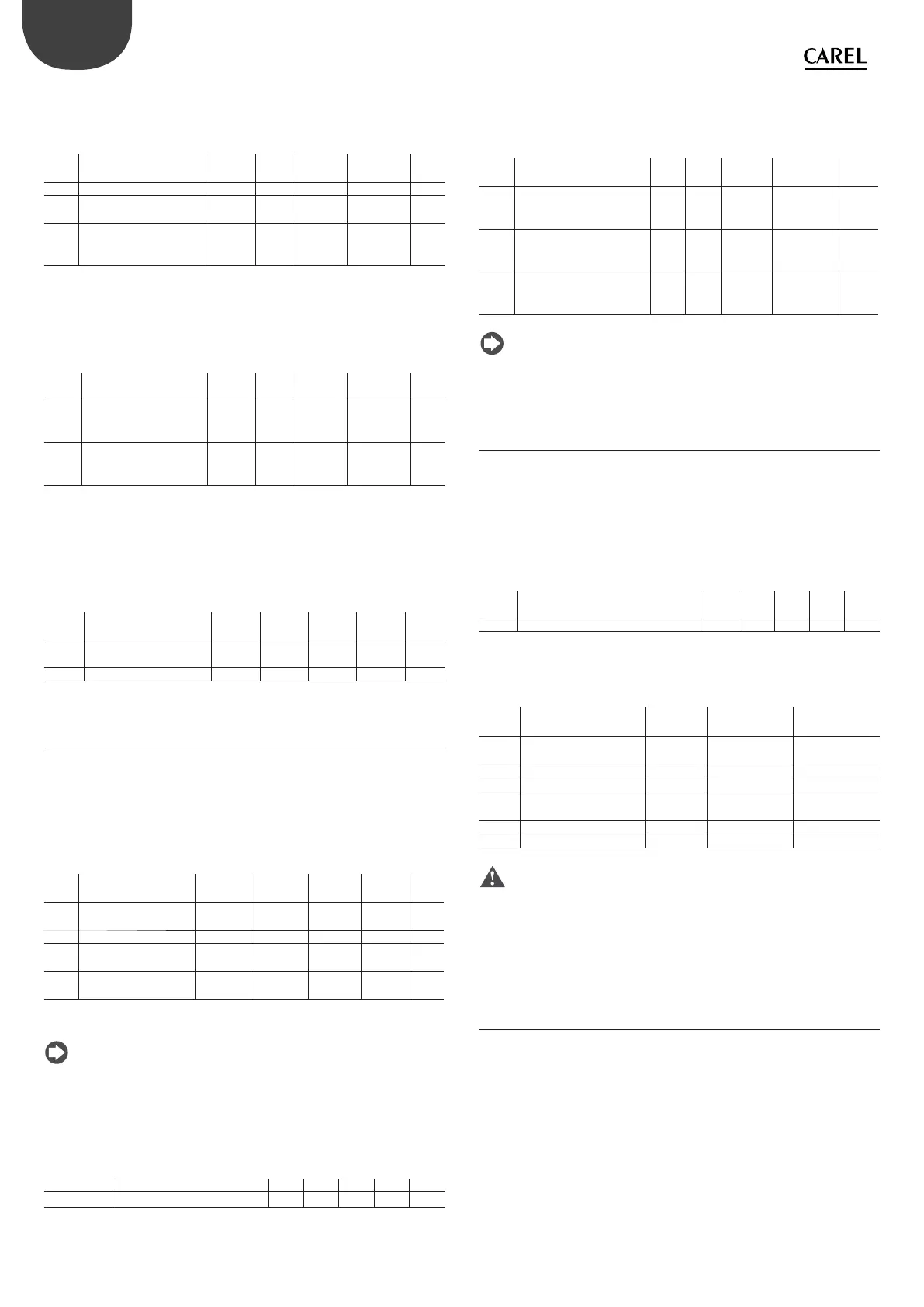

Mod.

add.

Description Def Min Max U.M. R/W

103 Autotuning 0/1=not active/start 0 0 1 - R/W

Tab. 4.u

Below a summary table with the electric data estimated according to the

type of motor. Where indicated at the end of the procedure, the parameters

are set at zero (0).

Mod.

add.

Description PM

Brushless

Asynchronous

vect.

Asynchronous

V/f

45 Motor magnetizing

current

NO(0) YES NO

46 Stator resistance YES YES YES

47 Rotor resistance NO(0) YES NO

48 Ls stator inductance or

Ld inductance

YES, Ld YES, Ls NO

49 Leakage factor NO(0) YES NO

50 Lq inductance YES NO(0) NO

Tab. 4.v

Important:

• Autotuning can only be performed when a motor is connected. At the

start of the procedure, the motor must be at a standstill;

• the end of the Autotuning procedure is signalled by the “Autotuning”

parameter and from bit7 of the “Status register”, which are automatically

taken back to 0.

4.6 Controls before commissioning

Before commissioning, check that:

• the drive output current is greater than or equal to the rated current or the

maximum envisioned for the motor;

• the work voltage range is correct

• the section of the power supply cables is correct;

• the maximum section and length of the motor cables is correct and that

they are connected in compliance with the wiring diagrams;

• all of the control inputs are connected correctly.

Loading...

Loading...