ENG

“Power+” +0300050EN - rel. 2.3 - 08.06.201221

5. FUNCTIONS

5.1 Inputs and outputs

Inputs

The inputs include:

1. the single or three-phase power supply, depending on the model, which

must be connected selecting suitable cables and fuses according to the

table in paragraph 9.1;

2. the “Safety Torque O ” safety digital input, to which an alternating or

direct voltage source is connected along with a safety device. See the

main connection layout;

3. the PTC thermistor for motor overtemperature protection. Must be

selected for motor protection and in a way that at the alarm temperature

the resistance is > 2600 ohm.

Important: in order to use the PTC input, the motor overtemperature

alarm must be enabled. See the paragraph 8.5.

Outputs

The drive outputs include:

1. the motor output, to which the cables must be connected, which are

dimensioned according to the table in paragraph 9.1;

2. the relay output.

5.2 Relay con guration

The relay function can be programmed and can indicate a functioning

condition of the drive or an alarm. See the chapter 8 “ALARMS” for the latter

case. The relay contact closes if the corresponding event occurs.

Mod.

add.

Description Def Min Max U.M. R/W

26 Relay con guration

0: drive in alarm

1: fan running

2: drive overtemperature alarm

3: motor overtemperature alarm

4: motor overload alarm

5: overvoltage alarm

6: undervoltage alarm

7: speed derating in progress

8: motor running

008-R/W

Tab. 5.a

5.3 Minimum and maximum output

frequency

The parameters allow to set the minimum and maximum limit for the drive

output frequency. The frequency set point must also be within the limits

xed by minimum and maximum frequency, otherwise it is not accepted.

Mod.

add.

Description Def Min Max U.M. R/W

6 Maximum output frequency 0 0 5000 0.1Hz R/W

7 Minimum output frequency 0 0 5000 0.1Hz R/W

Tab. 5.b

5.4 Direction of rotation inversion

During drive commissioning, in order to change the direction of rotation of

the motor, it is possible to swap over two of U, V, W wires. In the event of

application with compressors, there is only one motor rotation direction. In

other cases it is possible also to enable the reverse direction of rotation with

the relative parameter.

Mod.

add.

Description Def Min Max U.M. R/W

8 Reverse speed enable 0/1 = no/yes 0 0 1 - R/W

Tab. 5.c

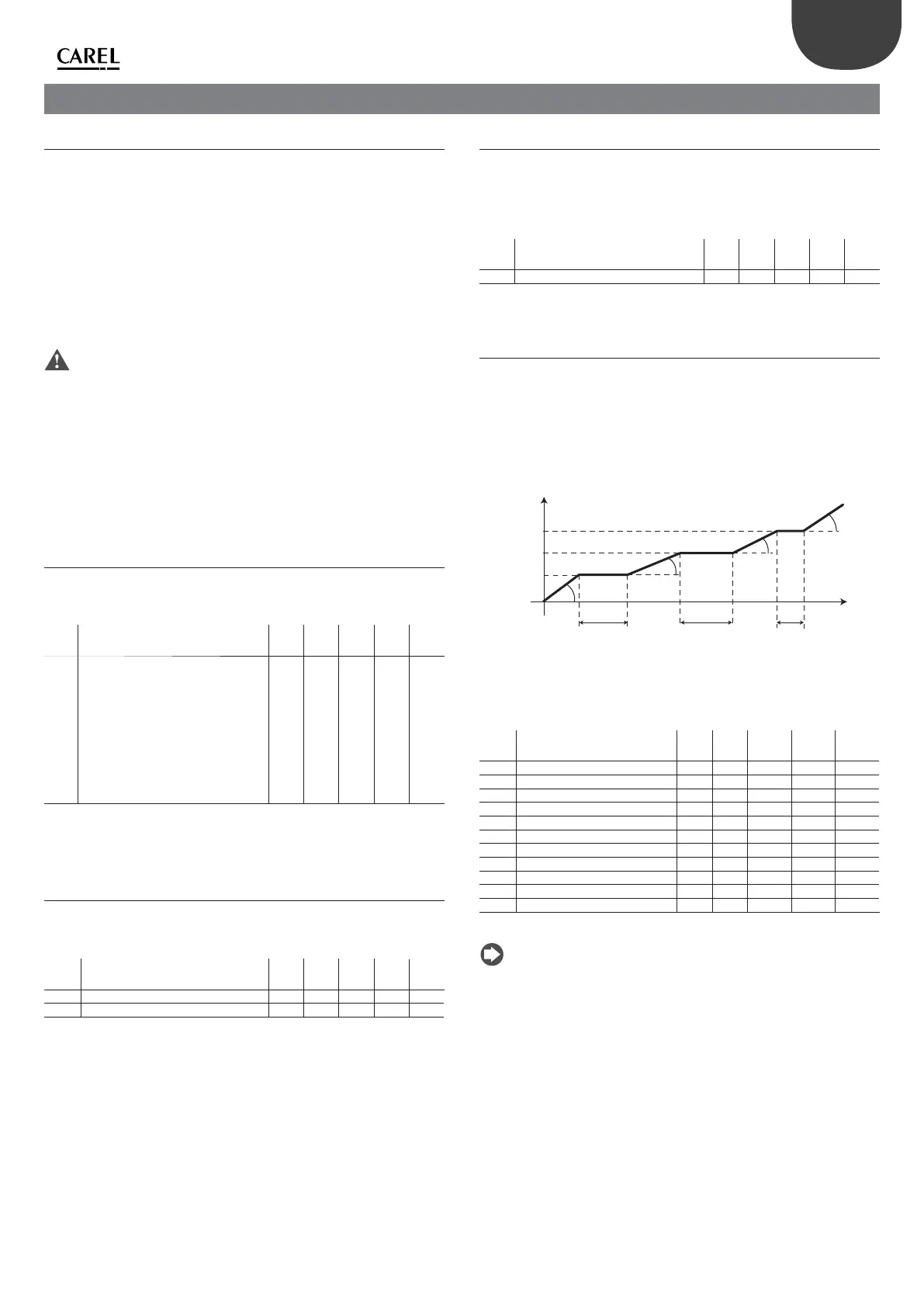

5.5 Speed pro le

Power+ has been designed with a programmable speed pro le for adaptation

to the features requested on compressor start-up. Once the speed pro le has

been selected it is also possible to establish the method of execution. The

pro le is designed by three frequencies (f1, f2, f3), which must be reached

with three linear ramp trends, de ned via three accelerations (a1, a2, a3).

Once the frequency (i=1, 2, 3) has been reached, the frequency value

remains for the time ti (i=1, 2, 3). Regarding decrease in speed, it is possible to

set just one deceleration.

f1

t2

t1

f2

f3

t3

a1

a2

a3

a4

f (Hz)

t

Fig. 5.a

Key

f1/ f2/ f3

Frequency 1/2/3

f

Frequency

a1/a2/a3/a4

Acceleration 1/2/3/4

t

Time

t1/ t2 /t3

Delay 1/2/3

Mod.

add.

Description Def Min Max U.M. R/W

12 Speed pro le: frequency 1 0 0 5000 0.1Hz R/W

13 Speed pro le: frequency 2 0 0 5000 0.1Hz R/W

14 Speed pro le: frequency 3 0 0 5000 0.1Hz R/W

15 Speed pro le: acceleration 1 60 0 500 0.1Hz/s R/W

16 Speed pro le: acceleration 2 60 0 500 0.1Hz/s R/W

17 Speed pro le: acceleration 3 60 0 500 0.1Hz/s R/W

18 Speed pro le: acceleration 4 60 0 500 0.1Hz/s R/W

19 Speed pro le: stand-by time 1 0 0 600 s R/W

20 Speed pro le: delay 2 0 0 600 s R/W

21 Speed pro le: delay 3 0 0 600 s R/W

23 Speed pro le: deceleration 60 0 500 0.1Hz/s R/W

Tab. 5.d

Note: it is recommended to use the values indicated by CAREL in

relation to the compressor used, as they guarantee the functioning mode

speci ed by the manufacturer. Alternatively it is possible to set a simple pro le

(f2=f3=Fmax; t1=t2=t3=0; a2=a3=a4=maximum acceleration allowed) and

refer management of the accelerations and delay times to the external

control. However, in this case it is necessary to keep the values of a1 and f1

indicated by CAREL, as they are critical for the compressor start-up phase.

Loading...

Loading...