ENG

“Power+” +0300050EN - rel. 2.3 - 08.06.2012 8

2. INTRODUCTION

Power+ is a drive designed to control compressors with sensorless-brushless

permanent magnet (PM) motors (BLDC/BLAC) or asynchronous induction

motors. For the latter, vector or V/f control can be selected. The drives can

also be used in some applications with fans and pumps, and consequently

the device o ers exible use in the air-conditioning and refrigeration

sectors. It is tted for panel installation or with heat sink outside of the panel.

Con guration and programming, as well as the Run/stop controls and speed

reference, are managed by a CAREL pCO controller or any controller device

via RS485 serial connection using the Modbus® protocol in master mode.

To suppress current harmonics:

• on single-phase models, during installation a toroidal coil, supplied with

the drive, needs to be connected for active power factor correction (PFC);

• on three-phase models, connection of a DC choke is optional (available for

purchase as an accessory), if compliance with EN61000-3-12 is required.

2.1 Functions and main features

In summary:

• compact dimensions for assembly in electrical panels;

• operation at ambient temperatures from -20 to 60°C;

• can be installed in residential and industrial environments;

• connection via serial network to Master programmable controller;

• network address can be con gured by setting the dipswitches directly on

the drive;

• can control various types of compressors;

• safety digital input (Safety Torque O );

• dedicated input for PTC thermistor or thermostat to monitor motor

overtemperature;

• panel installation or with heat sink outside of the panel, to optimize the

dissipation of heat inside the electrical panel;

• electrical connections can be made without needing to remove the plastic

cover;

• programmable acceleration curve to adapt to the required speci cations

when starting compressor;

• high switching frequency to limit motor noise;

• detailed information on drive status via numerous read-only variables;

• protection functions for the drive (short-circuit, overcurrent, earth fault,

overvoltage and undervoltage on the bus, overtemperature), motor

(overtemperature and limitation of current delivered) and system (Safety

Torque O input, communication failure).

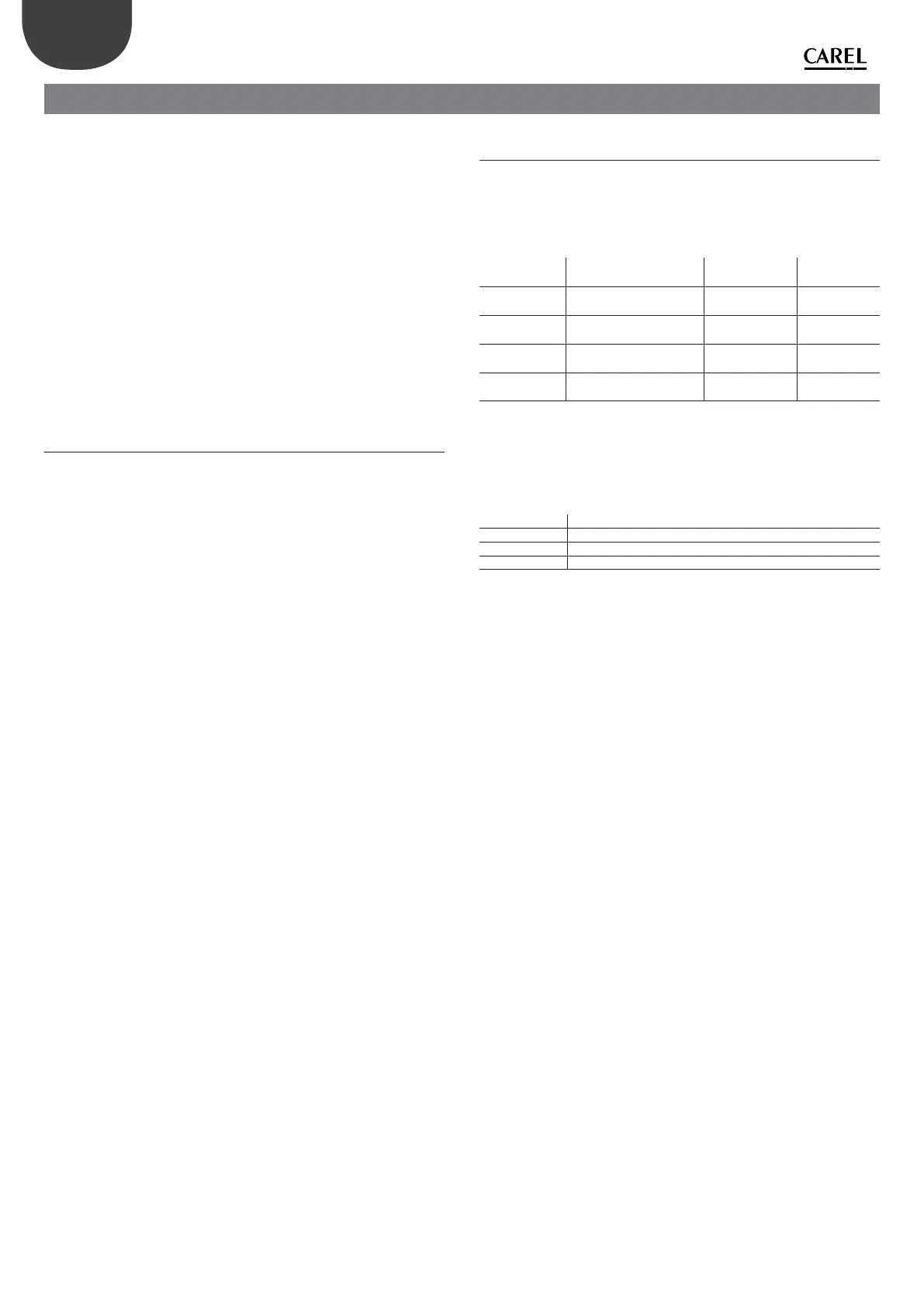

2.2 Models

The models di er due to power supply and rated output current as well as

for type of cooling:

• traditional with forced air cooled nned heatsink – frame sizes 1 and 2.

• coldplate, with plate for coupling to auxiliary cooling circuit devices (not

supplied) – frame size 3

Code Power supply Nominal output

current (A)

Frame size (*)

PSD0012200

PSD0012A00

200…240Vac ± 10%, 1~ 12

1

3

PSD0016200

PSD00162A0

200…240Vac ± 10%, 1~ 16

2

3

PSD0014400

PSD00144A0

380…480 Vac ± 10%, 3~ 14.5/18

1

3

PSD0022400

PSD00224A0

380…480 Vac ± 10%, 3~ 22.5

2

3

Tab. 2.a

(*) For the dimensions see par. 3.3 and 3.11

For Coldplate models PSD00***A* see paragraph 3.11

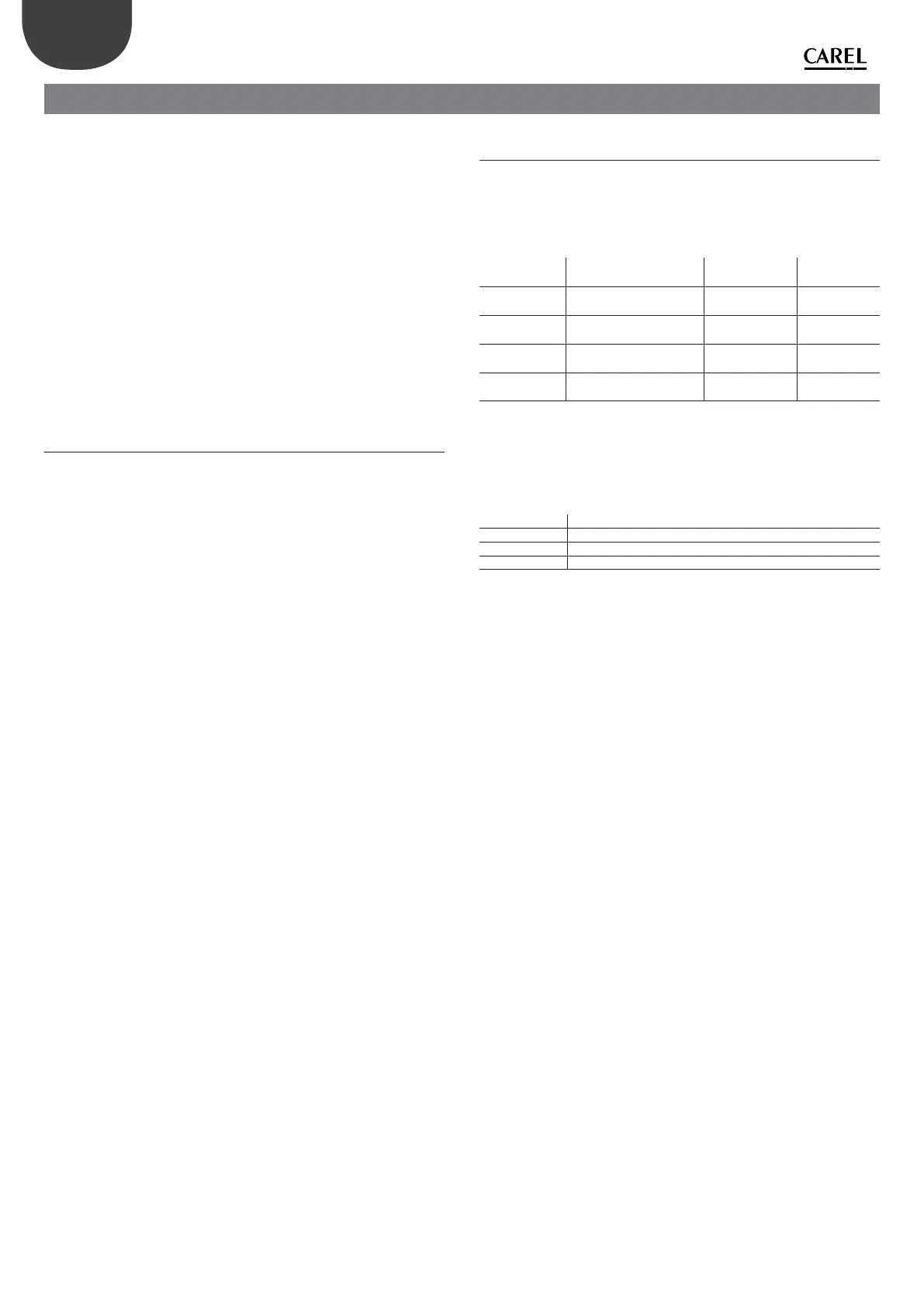

Accessories

Code Description

PSACH10000 DC choke for PSD00144*0

PSACH10100 DC choke for PSD00224*0

PSARF10000 EMI lter CNW102.1/30 for PSD00**2*0

Tab. 2.b

Loading...

Loading...