ENG

“Power+” +0300050EN - rel. 2.3 - 08.06.201231

8. ALARMS

8.1 Types of alarm

There are two types of alarm:

• drive malfunctioning alarms;

• motor malfunctioning alarms.

Among the status variables it is possible to check the presence of Modbus®

communication alarms.

Important: All alarms stop the motor and must be restored using

the alarm reset command:

Pr.101 = 1

followed by the command:

Pr.101 = 0

to resume the initial state.

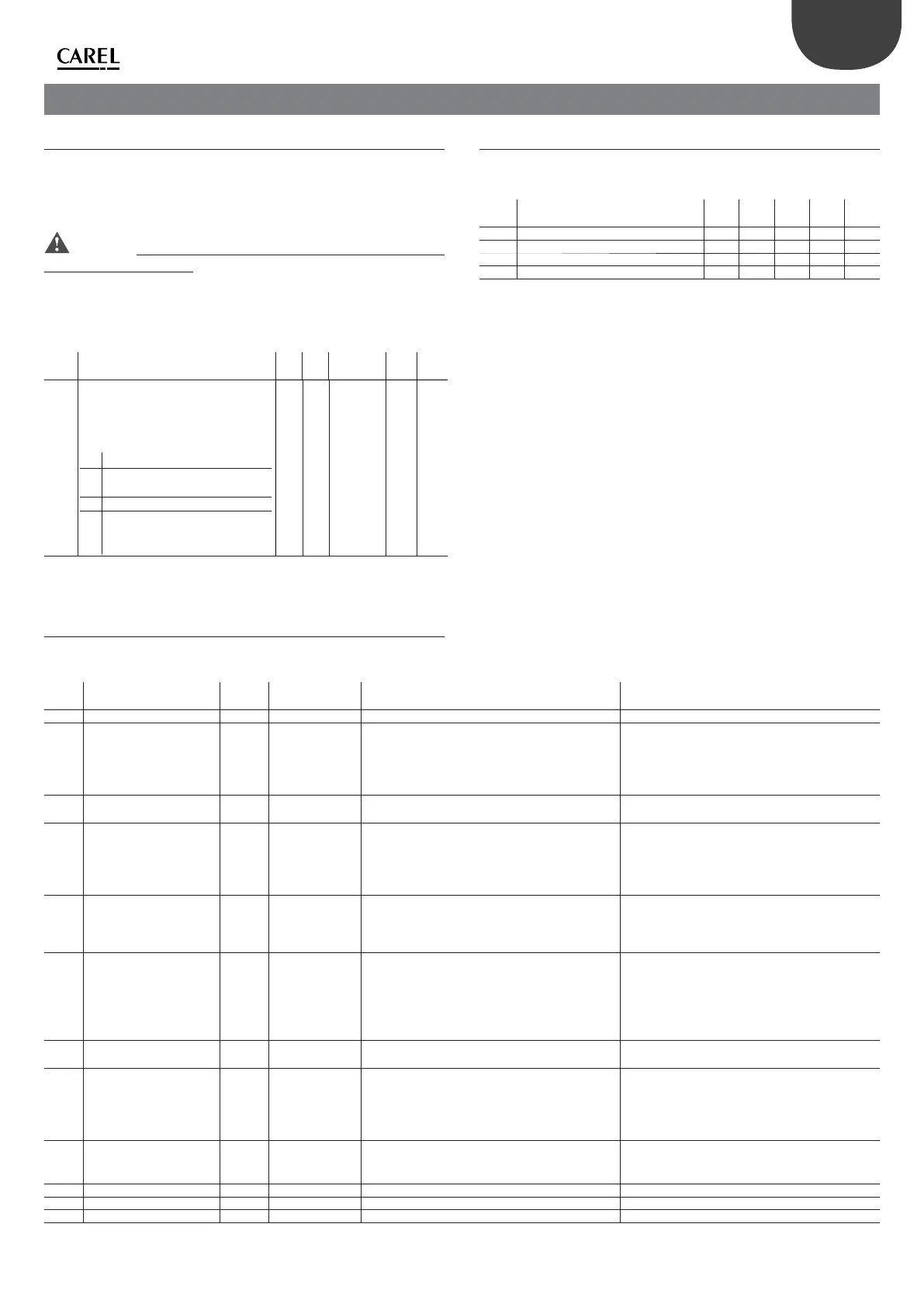

Mod.

add.

Description Def Min Max U.M. R/W

101 Reset (3 bit parameter)

The particular reset comand is executed

when the related bit changes from 0 to

1. After that the bit has to be cleared to

0 again.

bit meaning

0 alarms reset and updating of

communication parameters

1 parameters reset at default values

2 reset ag check drive switch on

and switch o (see speed register,

bit2)

0 0 allowable

values:

1, 2 ,4

- R/W

Tab. 8.a

8.2 Alarms log

The most recent 4 alarms are memorised in a FIFO type alarms queue. The

last alarm memorised is visible in the Alarm 1 status variable.

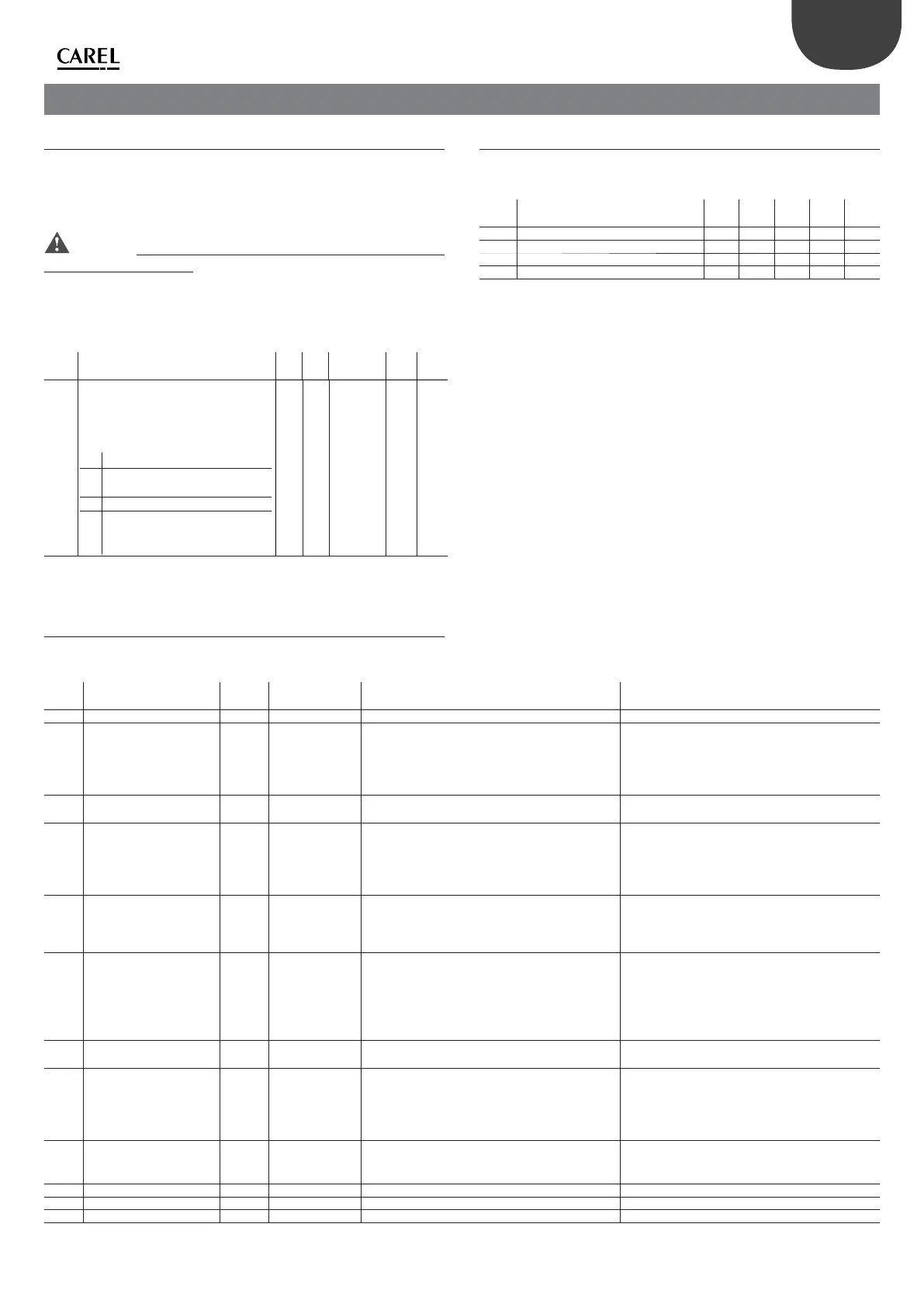

Mod.

add.

Description Def Min Max U.M. R/W

137 Alarm 1 ----R

138 Alarm 2 ----R

139 Alarm 3 ----R

140 Alarm 4 ----R

Tab. 8.b

8.3 Alarms table

The alarm code is given in the Alarm 1...4 parameters and in the alarm code

parameter (Modbus®=105)

Alarm

code

Description Relay

alarm

Reset Possible cause Solutions

0 No alarm - - - -

1 Overcurrent (*) reset command The drive has detected a current supplied that is too

high due to:

- sudden strong load increase;

- acceleration that is too high;

- wrong parameters values or inadequate motor.

Check the load, the dimension of the motor and

the cables. Decrease acceleration. Check the motor

parameters..

2 Motor overload (*) reset command The current supplied has exceeded the rated current

over the maximum time accepted

3 Overvoltage (*) reset command The DC voltage of the intermediate circuit has

exceeded the limits envisioned due to:

- deceleration that is too high;

- high over-voltage peaks on the power supply

network.

Decrease deceleration.

4 Undervoltage (*) reset command The DC voltage of the intermediate circuit is below

the limits envisioned due to:

- insu cient power supply voltage;

- fault inside the drive.

In the event of temporary cut-o of the power

supply, reset the alarm and re-start the drive. Check

the power supply voltage.

5 Drive overtemperature (*) reset command The temperature inside the drive has exceeded the

maximum level allowed.

Check that the quantity and ow of cooling air are

regular. Check that there is not dust in the heat sink.

Check the environment temperature. Ensure that

the switching frequency is not too high with respect

to the environment temperature and the motor

load.

6 Drive undertemperature (*) reset command The temperature inside the drive has exceeded the

minimum level allowed.

7 Overcurrent HW (*) reset command The drive has detected an istantaneous current

supplied that is too high due to:

- sudden strong load increase;

- motor cables short circuit;

- wrong parameters values or inadequate motor.

Check the load, the dimension of the motor and the

cables. Check the motor parameters.

8 Motor overtemperature (*) reset command The temperature detected by the PTC thermistor

corresponds to a resistance > 2600 ohm.

Reduce the motor load.

Check motor cooling.

9 IGBT module error (*) reset command Internal fault Call for assistance

10 CPU error (*) reset command Loss of data in memory Call for assistance

11 Parameter default (*) reset command Execution of reset parameter default command

Loading...

Loading...