ENG

“Power+” +0300050EN - rel. 2.3 - 08.06.2012 18

4. STARTUP

Important: Power+ can pilot various types of compressors with

permanent magnetic motors (PM) brushless BLDC/BLAC sensorless or

asynchronous induction motors. To set the parameters of a particular

compressor, consult the values indicated by CAREL in the document

“Power+: compressors parameters tables”, code +0300051IE, available, also

prior to purchase, upon request.

4.1 Con guration

The con guration of the drive consists in setting the various types of

parameters that regard:

1. the network communication: network address, data communication

baudrate, data communication parity;

2. the selection of the type of motor control;

3. the motor plate data;

4. the motor electric data;

5. motor start-up;

6. the motor control in regenerative functioning mode (load deceleration

with high inertia);

7. the proportional and integral regulation (PI) of the speed.

If the motor electric data (e.g.. resistances, inductance) are not known or are

believed not to re ect the e ective data (for example due to the length of

the motor cable), the Autotuning function can be used. See paragraph 4.5.

Note: once the communication parameters are set and the type of

motor and control selected, the setting of the parameters of points 3...7

depends on the type of motor.

Network communication

Network address

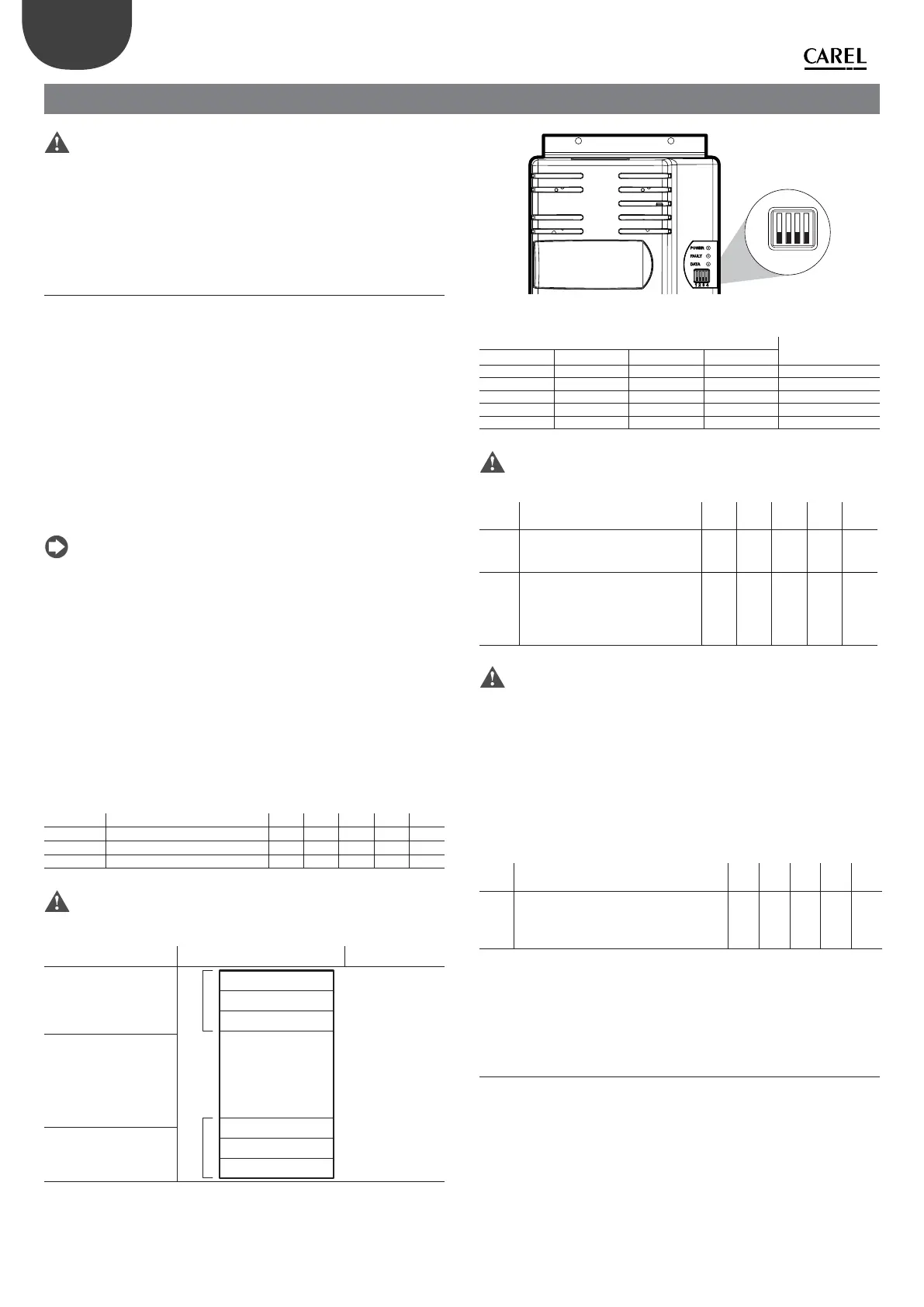

The con guration and the programming of the Power+ drive, as well as

the run/stop commands and the speed reference are managed by a CAREL

pCO control from any BMS (Building Management System) via RS485 serial

connection with ModBus® protocol. The ModBus® network address that can

be set from 1 to 247. This number is made up from the base address that can

be set from the parameter and the address of the 4 dip-switches present on

the drive, which goes from 0 to 15. By changing the base address in steps of

16, the entire interval can be covered.

Communication baudrate/communication parity

Mod. add. Description Def Min Max U.M. R/W

32 Base address 1 1 232 - R/W

121 Dip-switch address - 0 15 - R

120 Network address - 1 247 - R

Tab. 4.a

Important: the drive only reads the network address on switch on or

after a reset control

Dip-switch address Network address

Base address=1

1+0=1

1+15=16

...

232+0=232

232+15=247

0

15

...

0

15

Base address=232

Tab. 4.b

The address of the dip-switches in the drive is set manually as indicated

below.

1

ON

OFF

234

Fig. 4.a

Dip-switch address

Dip-switches Address

Dip-switch

1234

OFF OFF OFF OFF 0

ON OFF OFF OFF 1

OFF ON OFF OFF 2

………… …

ON ON ON ON 15

Tab. 4.c

Important: modify the network address via the dip-switches only with

drive o .

Mod.

add.

Description Def Min Max U.M. R/W

30 Data communication baudrate

0 = 9600 bit/s

1 = 19200 bit/s

101-R/W

31 Data communication parity and

stop bits

0 = none (2 stopbits),

1 = even (1 stopbits),

2 = odd (1 stopbits),

002-R/W

Tab. 4.d

Important: the modi cation of the “Communication baudrate” and

“Communication parity” parameters only becomes e ective on the next

switch on or reset command.

The transmission speed can be selected between 9600 and 19200 bit/s. All

devices connected in the serial network must have the same communication

baudrate and the same data communication parity.

Motor control mode setting

Power+ allows to drive compressors with permanent magnetic motors (PM)

brushless BLDC/BLAC sensorless or asynchronous induction motors. For the

latter it is possible to select between vector or V/f control.

Mod.

add.

Description Def Min Max U.M. R/W

0 Motor control mode

0 = PM brushless motor

1 = asynchronous motor with vector control

2 = asynchronous motor with V/f control

0 0 2 - R/W

Tab. 4.e

Below nd the list of parameters to be set according to the type of motor and

control. Follow the steps described in paragraphs 4.2 or 4.3 or 4.4, on the basis

of the type of motor control selected.

4.2 A - PM motor (brushless)

Motor data plate

Frequency/voltage/rated current/power factor

The base frequency is the frequency at which the base voltage is applied.

Base frequency and base voltage are relative to a generic point in the

voltage/frequency curve speci ed in the motor data sheet. The rated current

is the current at full load. The power factor is not used in this motor, but it is

recommended to set it at 100 (=1.00) for future compatibility.

Loading...

Loading...