ENG

“Power+” +0300050EN - rel. 2.3 - 08.06.201223

Mod.

add.

Description Def Min Max U.M. R/W

35 V/f boost voltage 0 0 250

(25.0)

% Motor base

voltage

R/W

36 V/f freq.cy adjustment 0 0 1000

(100.0)

% Motor base

frequency

R/W

37 V/f voltage adjustment 0 0 1000

(100.0)

% Motor base

voltage

R/W

Tab. 5.j

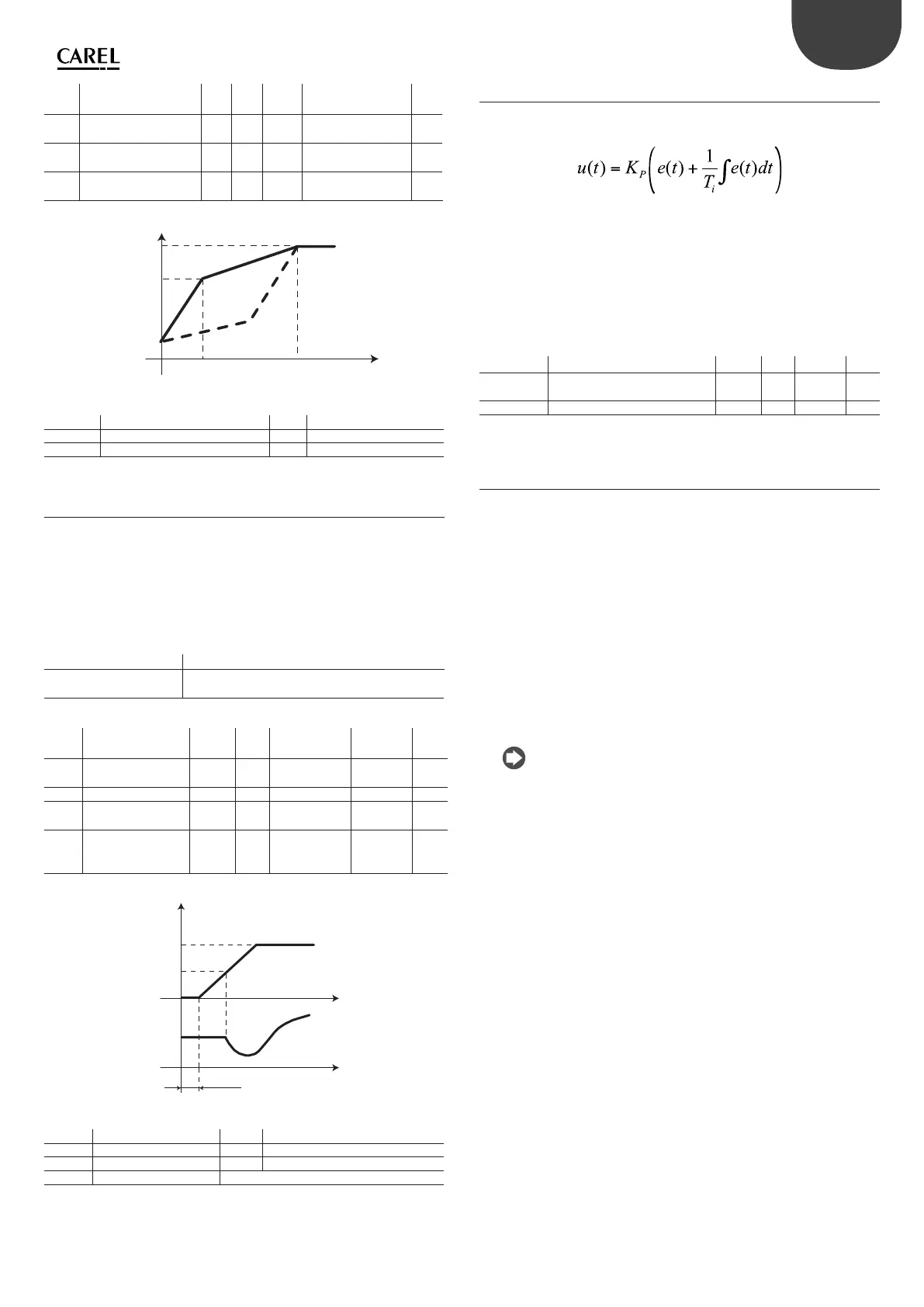

f (Hz)

Un (V)

fn

V_m

f_m

U_boost

Fig. 5.e

Key

fn Rated voltage Un Rated voltage

f_m Intermediate frequency V_m Intermediate voltage

U_boost Voltage boost f Frequency

5.11 Motor control on start-up

To increase torque on start-up, Power+ envisions:

1. for PM brushless motors and for asynchronous motors with vectorial

control, a start-up current for the magnetizing time at frequency 0 and

then to the frequency de ned at the “Maximum frequency for starting

current” parameter. The value of the start-up current is de ned by the

following formulas.

STARTUP CURRENT

PM brushless motor Asynchronous motor with vectorial control

(Motor rated current)*

*(Starting current)

(Magnetizing current)*

*(100+Starting current)

Tab. 5.k

Mod.

add.

Description Def Min Max U.M. R/W

45 Motor magnetizing

current

0 0 Rated output

current

0.1A R/W

51 Magnetizing time 100 0 30000 0.001s R/W

57 Starting current 200

(20.0%)

0 1000

(100.0%)

0.1% R/W

58 Max frequency for

starting current

0 0 1000

(100.0%)

0.1%

Motor base

frequency

R/W

Tab. 5.l

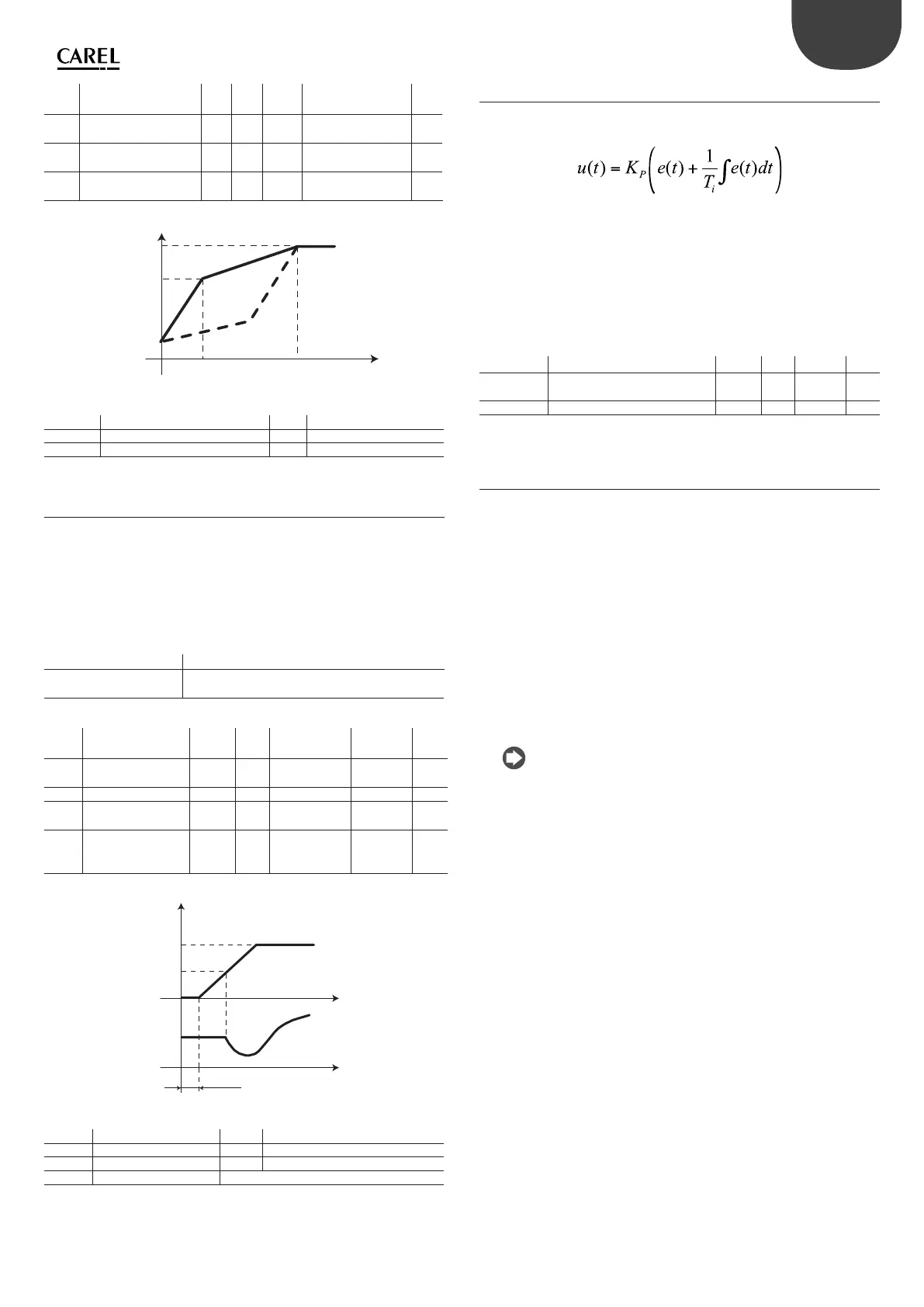

f_set

t

I_start

t_magn

0

0

f_start

f(Hz)

t

I

Fig. 5.f

Key

f_set Frequency set point f_start Max frequency for starting current

t_magn Magnetizing time I_start Start-up current

t Time f Frequency

I Current

2. for asynchronous motor with V/f control: see the “V/f control for

asynchronous motor” paragraph.

5.12 PI parameters

Speed regulation takes place via a PI type control, which in its simplest form

is characterised by the following law:

Note that the control is calculated as the sum of the two separate

contributions, proportional and integral:

• the proportional action varies the control action proportionally to the

error. Therefore the greater the value of Kp (proportional gain) the faster

will be the response speed. The proportional action, alone, does not allow

the set point to be reached.

• the integral action varies the control action proportionally to the area of

the error. The lower the Ti (integral time) value, the more energetic the

control action. Moreover, the PI control tends to annul the error.

Mod. add. Description Def Min Max U.M.

55 Speed loop: Kp 250

(25.0)

0 2000

(200.0)

0.1%

56 Speed loop: Ti 500 1 1000 ms

Tab. 5.m

5.13 Commands

1. Run/stop:

• bit0: run control (Run=1) and stop control (stop=0) of the motor;

• bit1: setting the direction of rotation, clockwise (0) or anti-clockwise

(1). In order to have anti-clockwise rotation this must be previously

enabled with the “Reverse speed enable” parameter.

2. Reset:

• bit0: allows to cancel the alarms present in the alarms queue and to

update the address communication, data communication parity and

communication baudrate parameters. For example, the command

must be given after modi cation of the dip-switches in order to set

the network address.

• bit1: allows to set the parameters at factory value (default). When the

operation has taken place, the “Parameter default” alarm occurs. See

the alarms table.

• bit2: reset ag check drive switch on and switch o (see speed register,

bit2)

Note: the resets take place on transition of the respective bit from

zero to one and therefore it is necessary to take the bit at zero in order to

allow a successive reset action.

3. Frequency set point it is the set point that the motor must reach

following the “Run” command; the direction of rotation is given by the

bit1 of the Run/Stop command.

4. Autotuning: the command is given after having set the motor plate

data, if electric data is not available (resistances, inductance) of the

speci c motor. When autotuning has ended, the parameter 104 goes

automatically back to zero. See the chapter 4 “STARTUP”.

Loading...

Loading...