40

3. Inspect the bearing surfaces for evidence of wear or

damage. If bearing surface is worn or scored, or if the oil

pump is defective, the complete bearing head must be

replaced (see replacement bearing head package listed

below).

While bearing head is removed, inspect internal running

gear for obvious problems (broken rods or pistons).

Compressor

Replacement Bearing Head

Package

06CC, 16 to 37 Cfm, and all 06D 06DA660126

06CC, 50 to 99 Cfm, and all 06E 06EA660157

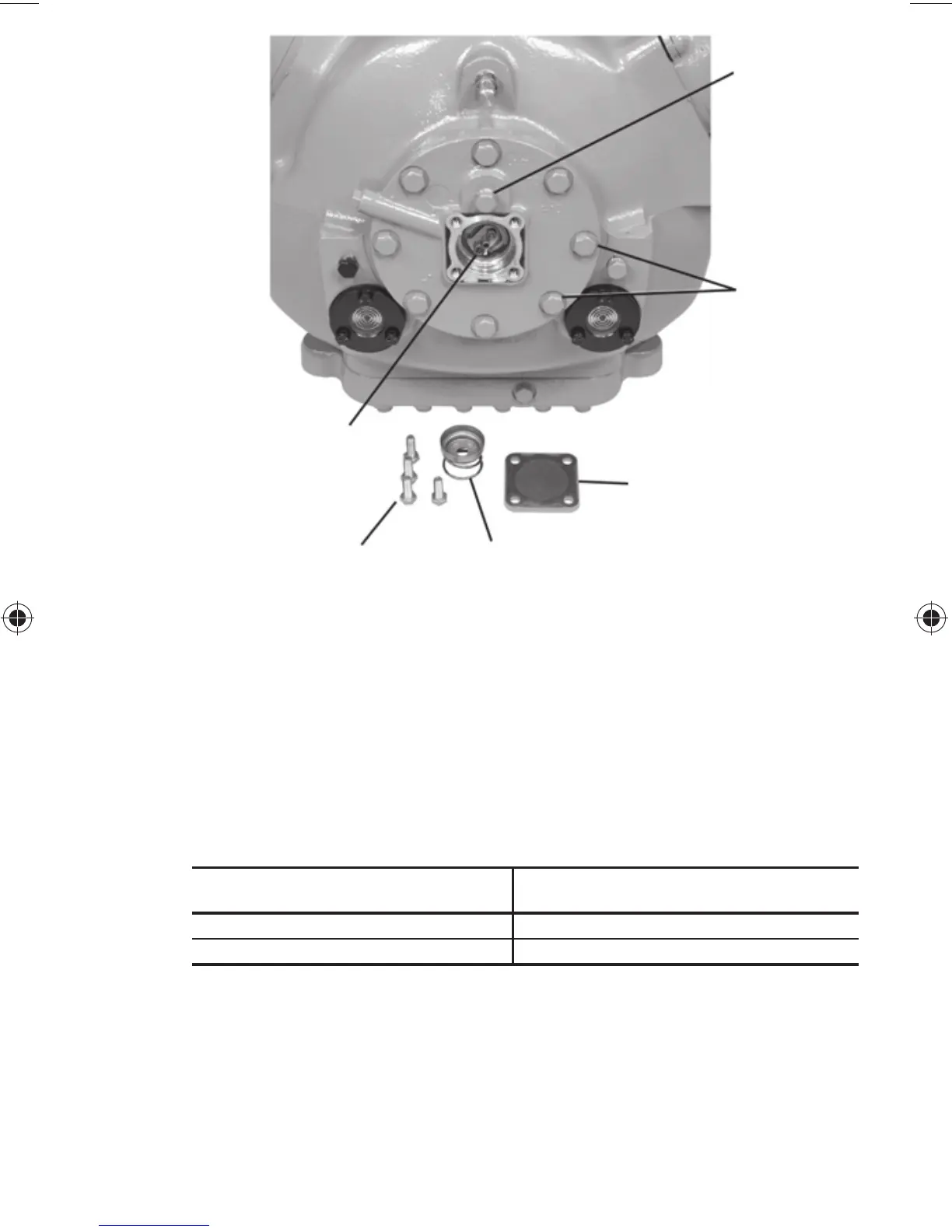

OIL

PRESSURE

TAP (1/4")

BEARING

HEAD CAP

SCREWS (8)

COVER PLATE

DRIVE

SEGMENT

CAP SCREWS (2)

BEARING HEAD COVER

CAP SCREWS (4)

OIL FEED GUIDE

VANE AND SPRING

Fig. 7 — Removing Pump End Bearing Head

(06E Compressor)

Loading...

Loading...