37

Table 34 — Minimum Flow Rates and Minimum Loop Volume — English

LEGEND

Table 35 — Minimum Flow Rates and Minimum Loop Volume — SI

LEGEND

START-UP AND OPERATION

Compressor crankcase heaters must be on for 24 hours be-

fore start-up. To energize the crankcase heaters, close the field

disconnect. Leave the compressor circuit breakers off/open.

The crankcase heaters are now energized.

NOTE: Refer to Start-Up Checklist on pages CL-1 to CL-8.

PRELIMINARY CHARGE (30MPA) — Refer to GTAC II

(General Training Air Conditioning), Module 5, Charging, Re-

covery, Recycling and Reclamation for charging procedures.

The 30MPA units (condenserless) are shipped with a nitro-

gen holding charge only. Leak check the 30MPA unit, dis-

charge and liquid lines, and the condenser. Be sure the liquid

line service valve is open. After leak check is completed, sys-

tem must be evacuated and dehydrated. Following the evacua-

tion, the system must be fully charged.

The liquid charging method is recommended for complete

charging or when additional charge is required.

Using the liquid charging method and charging by weight

procedure, charge the circuit with the amount of Puron refriger-

ant (R-410A) with the sum of the operating charge listed in Ta-

ble 36 for the base unit, the liquid line charge and the operating

charge of the condenser as the preliminary charge.

UNIT SIZE

FLOW RATE

NORMAL AIR CONDITIONING APPLICATION

Gal./Ton

PROCESS COOLING OR LOW AMBIENT

OPERATION APPLICATION

Gal./Ton

EVAPORATOR CONDENSER

Gal./Min Gal./Min Std Unit HGBP Digital Std Unit HGBP Digital

30MP015 22 22 12 2 N/A 12 3.4 N/A

30MP020 28 28 6 4 3 10 10 6

30MP030 43 43 6 4 3 10 10 6

30MP040 55 55 3 3 3 6 6 6

30MP045

64

64 3 3 3 6 6 6

30MP050

70

70 6 4 N/A 10 6 N/A

30MP055

77

77 6 4 N/A 10 6 N/A

30MP060

84

84 6 4 N/A 10 6 N/A

30MP065

91

91 6 4 N/A 10 6 N/A

30MP071

104

104 6 4 N/A 10 6 N/A

HGBP — Hot Gas Bypass

UNIT SIZE

FLOW RATE

NORMAL AIR CONDITIONING APPLICATION

L per kW

PROCESS COOLING OR LOW AMBIENT

OPERATION APPLICATION

L per kW

EVAPORATOR CONDENSER

L/s L/s Std Unit HGBP Digital Std Unit HGBP Digital

30MP015 1.4 1.4 13.0 8.6 N/A 13.0 13.0 N/A

30MP020 1.8 1.8 6.5 4.3 3.3 10.8 10.8 6.5

30MP030 2.7 2.7 6.5 4.3 3.3 10.8 10.8 6.5

30MP040 3.5 3.5 3.3 3.3 3.3 6.5 6.5 6.5

30MP045

4.0

4.0 3.3 3.3 3.3 6.5 6.5 6.5

30MP050

4.5

4.5 6.5 4.3 N/A 10.8 6.5 N/A

30MP055

4.9

4.9 6.5 4.3 N/A 10.8 6.5 N/A

30MP060

5.3

5.3 6.5 4.3 N/A 10.8 6.5 N/A

30MP065

5.8

5.8 6.5 4.3 N/A 10.8 6.5 N/A

30MP071

6.6

6.6 6.5 4.3 N/A 10.8 6.5 N/A

HGBP — Hot Gas Bypass

IMPORTANT: Before beginning Pre-Start-Up or Start-Up,

review Start-Up Checklist at the back of this publication.

The checklist assures proper start-up of a unit and provides

a record of unit condition, application requirements, system

information, and operation at initial start-up.

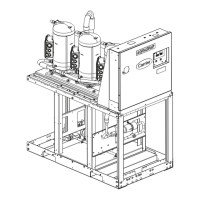

Fig. 25 — Sight Glass Location

CAUTION

Crankcase heaters are wired into the control circuit, so they

are always operable as long as the main power supply dis-

connect is on (closed), even if any safety device is open.

Compressor heaters must be on for 24 hours prior to the

start-up of any compressor. Equipment damage could result

if heaters are not energized for at least 24 hours prior to

compressor start-up.

Loading...

Loading...