KC_

SERIES

10

11. Caulk joints in wood frame as required. If wall

thickness is 7-in. or more, add aluminum flashing

over bottom of frame opening to ensure no water

can enter area between inner and outer wall.

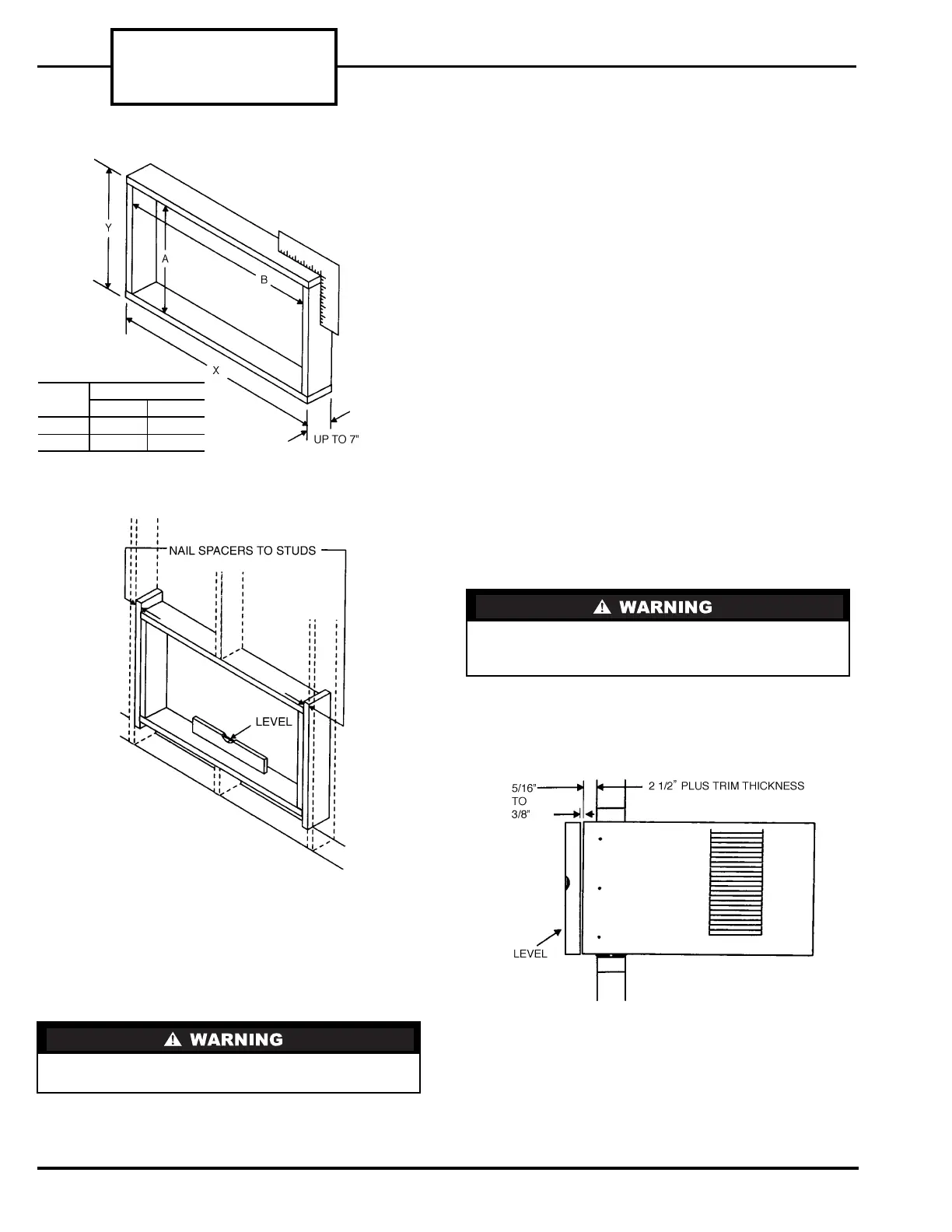

12. Remove the chassis from the unit cabinet.

13. Slide the empty cabinet into the wall opening and

into wooden frame. Approximately 2

1

/

2

in. of the

cabinet should be in the room. The rest of the cab-

inet should be positioned through and outside the

wall. See Fig. 23. Maintain proper slope for con-

densate drain operation. Bottom rail should be

resting firmly on bottom board of wooden frame.

14. Secure bottom rail to wood frame with two large

wood screws (1-in. long) using the two holes in the

bottom of the channel. See Fig. 24.

15. There are screw holes in the cabinet (4 each side,

4 top) which are used to secure the cabinet to the

wooden frame. With the cabinet in its final posi-

tion, drill holes in the wooden frame using the

screw holes in the cabinet as a guide. After the

holes have been drilled, secure the cabinet to the

wooden frame using field-supplied screws. See

Fig. 25.

16. Caulk around wood frame and wall opening on

outside wall for a water-tight seal.

17. Optional caulking between the cabinet and the

wooden frame may be done on inside wall. Caulk-

ing provides an air seal around the cabinet. Deco-

rative wood trim may be added to provide a more

pleasing appearance.

18. Lift chassis and carefully slide it into the cabinet.

Be sure that it is firmly seated towards the rear of

the cabinet.

19. Install the front panel.

20. Plug in the unit.

Be careful when handling chassis. Sharp edges on

coil fins can cause personal injury.

Do not push on the controls or the coil when

installing chassis. Damage to unit or personal

injury could result.

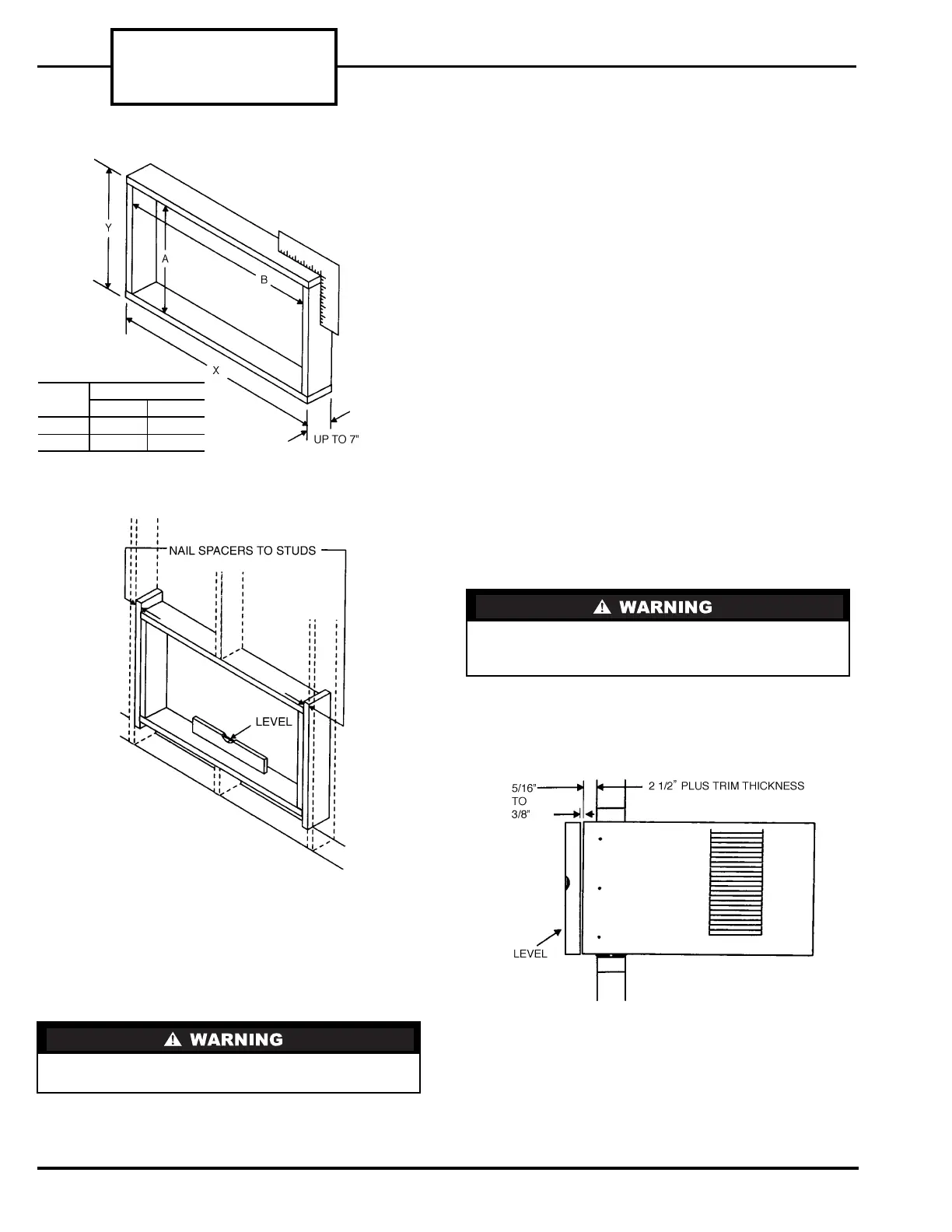

FIGURE 21 — FRAME CONSTRUCTION

UNIT

73KC_

DIMENSIONS (in.)

AB

101P 14.8 20.5

121P 15.7 22.8

FIGURE 22 — FRAME INSTALLATION

FIGURE 23 — CABINET LOCATION

IN WALL

Loading...

Loading...