7929 SW Burns Way Phone: 503 344-5085

Suite F

Wilsonville, OR sales@cascadiamotion.com

1/14/2021 RMS PM Hardware User Manual 10 of 54

Another option is to monitor the pressure in the cooling system. Typically the inverter would

be placed near the end of the cooling loop, just before the radiator. So a typical cooling

loop might look like pump outlet, inverter, radiator/reservoir, pump inlet. Typically the

reservoir is at ambient error pressure. So the inverter should be at a pressure that is higher

than ambient. If a pressure switch is placed at the input coolant port of the inverter it

should be able to detect that coolant is flowing.

Various types of coolant pressure switches exist. If a type is used that closes the switch

when the pressure is above a certain level is used then this could be inserted in series with

the ground connection of the forward/reverse switches (for VSM mode applications) or just

connected directly to one of the inputs for monitoring via CAN.

A pressure switch that closes when the pressure is above about 6 psi (~0.4 bar) should be

suitable for the PM100 and PM150. For the PM250 the required pressure is higher and

should be about 10 psi (~ 0.7 bar).

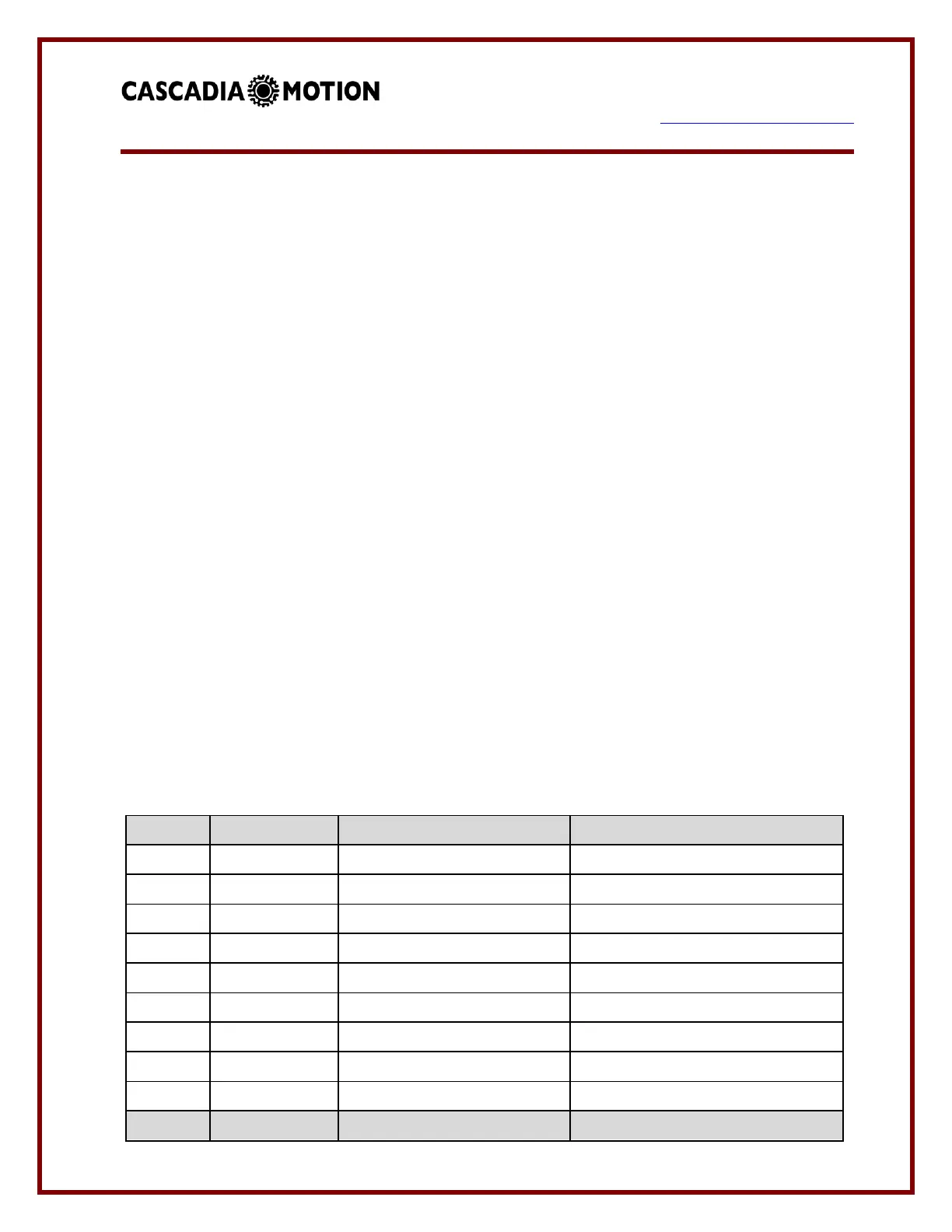

3.2 PM100/PM150 External Signal Connectors:

Two sealed automotive connectors are provided to connect to the internal I/O resources. J1

and J2 are standard AMPSEAL connectors by AMP/Tyco:

3.2.1 J1 – 35p AMPSEAL Plug 776164-1 with crimp contact 770854-1

GEN2 refers to PM100 Units w/ serial number less than 344

GEN3 refers to PM100 Units w/ serial number of 344 or greater and all PM150 units

Loading...

Loading...