8

• Digital display as standard that allows precise setting of the

welding current.

• Switch with two welding processes: electrode and TIG.

• Electrode Antisticking function.

•

Automatic “Hot Start” function which helps to achieve fast

and reliable arc striking.

•

Automatic “Arc Force” function to avoid electrode/piece stick-

ing during welding. It also promotes a reduction in the spat-

ter generated by the welding process.

• TIG welding with “Lift” striking.

• It has an IP 23 S protection class so that it can be used un-

der the heaviest working conditions.

•

The generator also conforms to all European Union stan-

dards and directives in force.

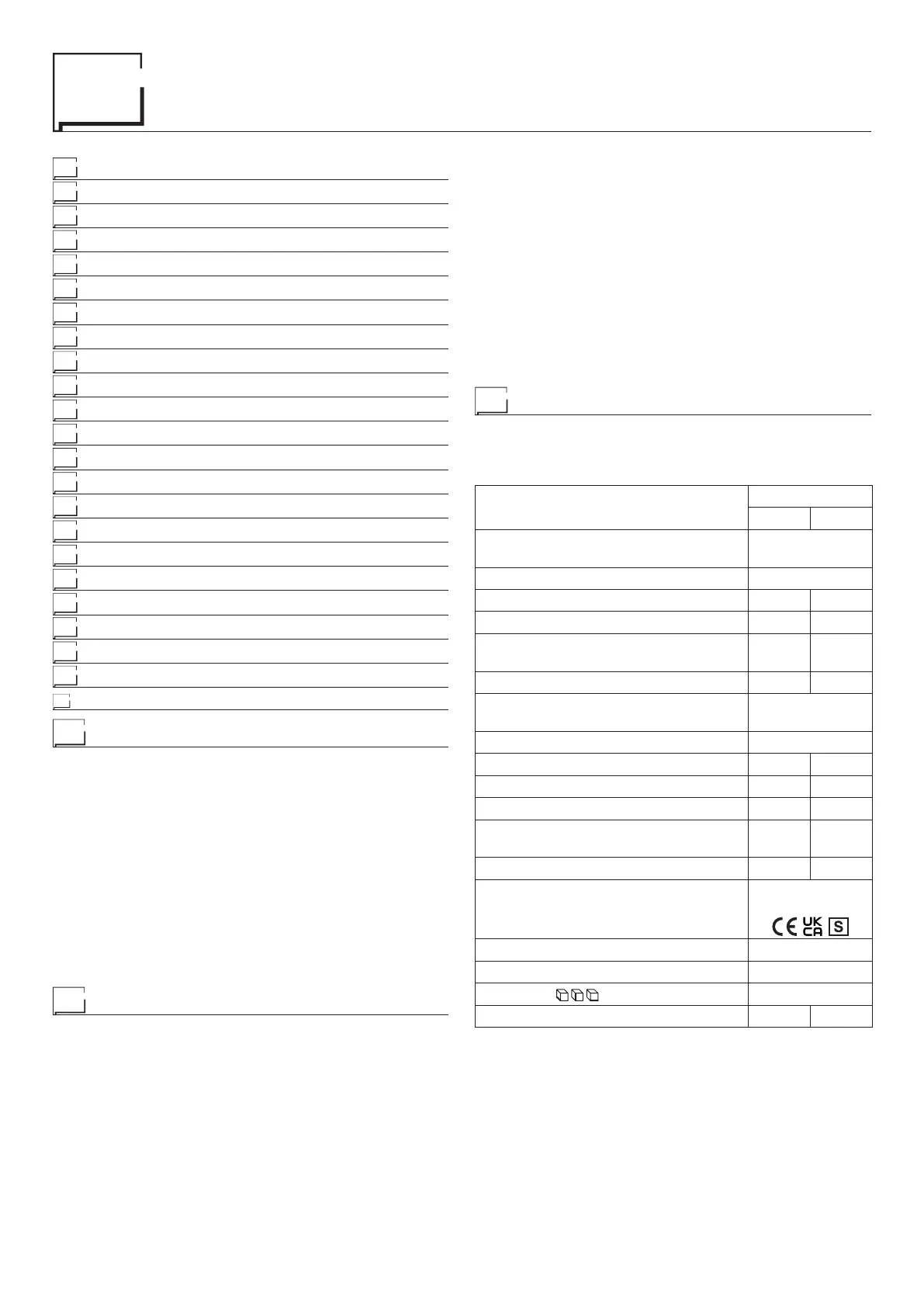

Technical data

The general technical data of the system are summarized in

table 1.

Table 1

Model

ROCK

160 200

Single-phase power supply

50/60 Hz

V 230 +/-10%

Mains supply: Z

max

(*) Ω 0,19

Power input @ I

2

Max kVA 8,2 10,4

Delayed fuse (I

2

@ 100%) A 16 25

Power factor / cosφ

0,62/

0,99

0,67/

0,99

Maximum efficiency degree η 0,82 0,81

Potenza assorbita a macchina

inattiva (IDLE state)

W 5

Open circuit voltage V 72

Current range A 10÷160 10÷200

Duty cycle @ 100% (40°C) A 95 105

Duty cycle @ 60% (40°C) A 105 110

Duty cycle @ X% (40°C) A

160

(20%)

200

(10%)

Usable electrodes mm 1,6÷4,0 1,6÷4,0

Standards

IEC 60974-1

IEC 60974-10

Insulation class IP 23 S

Protection class F

Dimensions

mm 315 - 260 - 135

Weight kg 4,3 4,6

(*) Mains supply Z

max

: maximum impedance value allowed for

the grid according to the EN/IEC 61000-3-11 standard.

WARNING: This equipment does not comply with EN/IEC

61000-3-12. If it is connected to a public low voltage system, it

is the responsibility of the installer or user of the equipment to

ensure, by consultation with the distribution network operator

if necessary, that the equipment may be connected.

Introduction

Thank you for buying our product.

In order to get the best performance out of the plant and ensure

the maximum lifespan of its parts, the use and maintenance in-

structions contained in this manual must be read and strictly

complied with, as well as the safety instructions contained in

the relevant folder. If repairs to the plant are required, we rec-

ommend that our clients contact our service centre workshops,

as they have the necessary equipment and personnel that are

specifically trained and constantly updated.

All our machines and equipment are constantly developed and

so changes may be made in terms of their construction and fea-

tures.

For further information on our products or to contact CEA, go to a

CEA authorised dealer or to CEA’s website at www.ceaweld.com.

Description

ROCK is a welding machine with inverter technology that can

be used, for professional welding, with rutile and basic elec-

trodes. It is extremely easy to use, guarantees excellent weld-

ing results and can be used anywhere thanks to its compact

size and reduced weight (workshops, maintenance, construc-

tion sites, etc.). The main characteristics of the ROCK weld

-

ing machine are:

• Reduced weight and size, easy-to-carry.

•

The weld machine has a strong handle all in one with the

frame, used for transporting the machine manually only.

•

The welding machine is also equipped with an adjustable and

removable shoulder strap that allows for easy and comfort-

able carrying on the shoulder.

•

The welding machine is equipped with a 3m ground cable

and electrode holder.

Introduction 8

Description 8

Technical data 8

Usage limits (IEC 60974-1) 9

How to lift up the machine 9

Open the packaging 9

Serial number 9

Installation 9

Connection to the electrical supply 9

Usage norms 10

MMA electrode welding (Fig. B) 10

TIG welding (Fig. C) 11

Maintenance 12

Possible problems and remedies 12

Procedure for welder assembly and disassembly 12

Electro topographical diagram 68

Colour key 70

Electro topographical diagram key 71

Meaning of graphic symbols on machine 72

Meaning of safety stickers 73

Meaning of graphic symbols on date plate 75

Spare parts list 77-78

Ordering spare parts 79

ENGLISH

EN

Loading...

Loading...