49/60

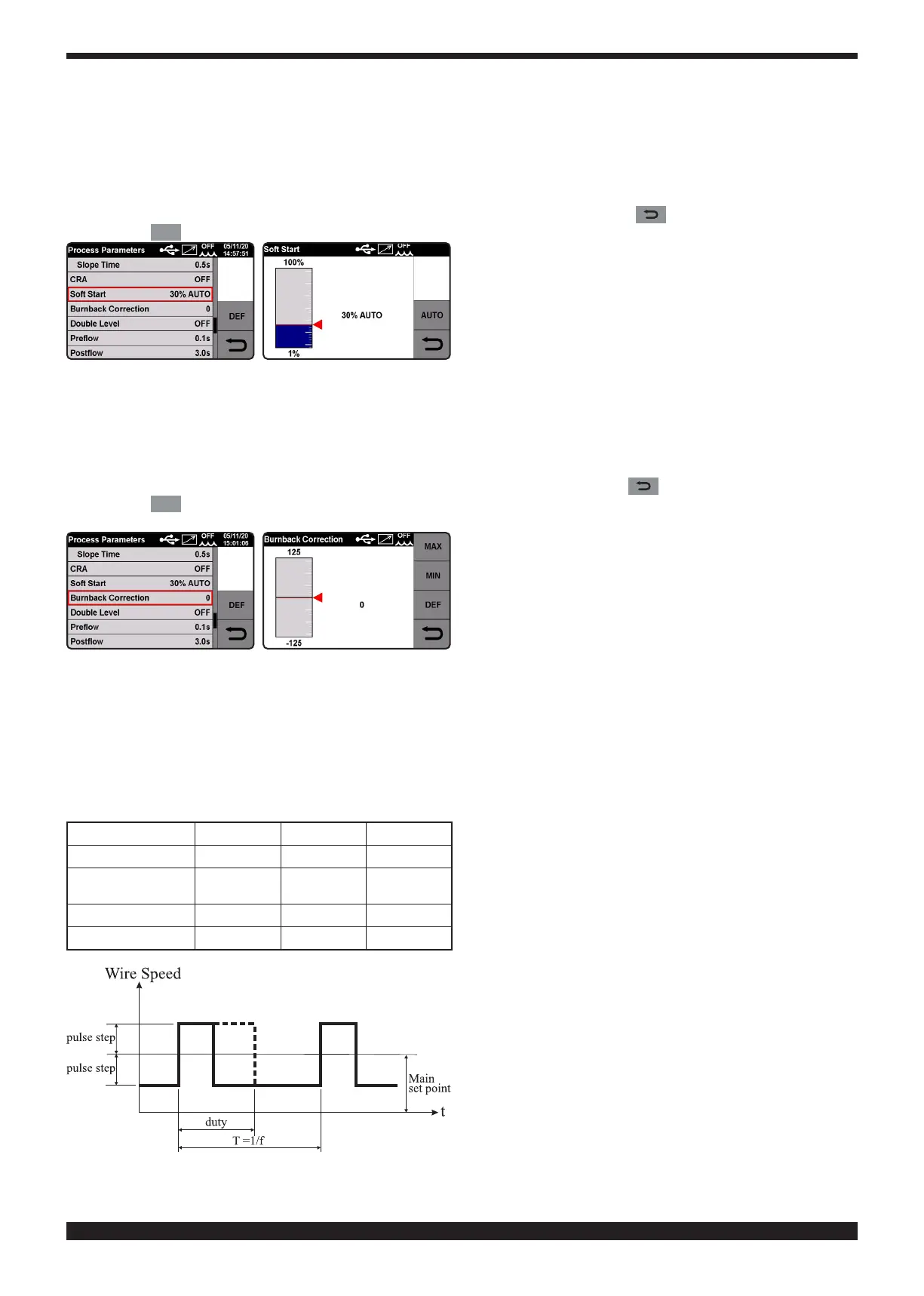

Soft Start�

Adjustment ranges from 0 to 100%. This is the wire speed expressed as a percentage of the speed set for welding,

before the wire touches the workpiece to be welded.

This adjustment is important for consistently achieving effective start-up.

The manufacturer adjustment is Auto (Default function)

Turn knob 2 to select the parameter and conrm the selection by pressing the knob.

Adjust the value by turning knob 2 Conrm the choice by pressing knob 2 or key .

Press the

DEF

key to restore factory settings.

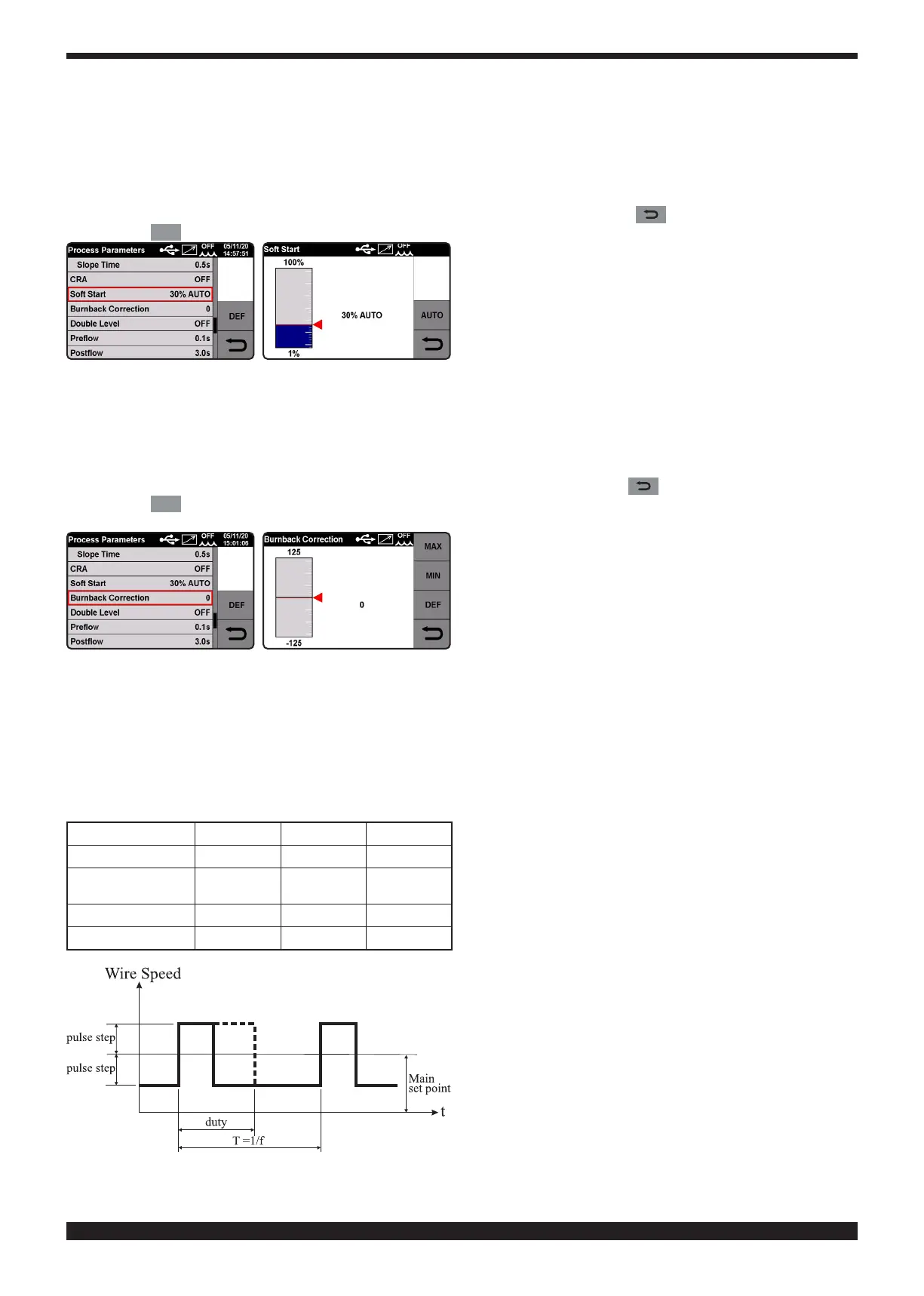

• Burnback Correction.

Adjustment ranges from -9.9 to +9.9%. Its purpose is to adjust the length of the wire coming out of the gas nozzle

after welding. A positive gure corresponds to more wire burnt.

The manufacturer's setting is 0 (Default function).

Turn knob 2 to select the parameter and conrm the selection by pressing the knob.

Adjust the value by turning knob 2 To conrm the selection, press knob 2 or key .

Press the

DEF

key to restore factory settings.

• Bi-level.

Active in synergic MIG/MAG processes only. This type of welding varies the current intensity between two levels.

Before setting bi-level welding, weld a short bead to determine the wire speed and thus the current to obtain the

optimum bead penetration and width for the type of weld required.

In this way the wire feed speed (and hence the corresponding current) is determined; the metres per minute that will

be set will be added to or subtracted from this value.

Before start working you should not forget that for a correct bead, the minimum overlap between one mesh and

another must be 50%.

MIN. MAX DEF

Frequency 0.1 Hz 5.0 Hz 1.5 Hz

Speed

difference

0.1 m/min 3.0 m/min 1.0 m/min

Duty cycle 25% 75% 50%

Arc correction -9.9 9.9 0.0

Loading...

Loading...