Page 18 •

CEDIMA

®

• Technical Documentation • All rights reserved as per DIN 34 • „Subject to modifications due to progressive development“ •

Sect. 3 - Installation and Operator’s Controls of the Bench Saw

Bench Saw CTS•81, L, XL

Operating Manual 70 9998 0329 / UK 003

• Problem: Electrical defect in the Bench Saw.

Remedy: Have the Bench Saw revised by a

qualified electrician.

3.6 Saw blade

3.6.1 Choosing the right type of saw blade

Attention:

Use only approved saw blades!

The blade shaft speed of the Bench Saw is exclu-

sively designed for cutting with diamond saw bla-

des. The Bench Saw may only be used for cutting

natural and artificial stone materials! Never use

the saw blades for cutting wood or metal.

The Bench Saws CTS•81 / CTS•81 L are designed

for the use of diamond saw blades with diameters

ranging from 350-400 mm. The CTS•81 XL is de-

signed for saw blade diameters not exceeding

350 mm. Saw blades with larger diameters must

not be installed on the Bench Saw.

The blade shaft speed of the Bench Saw is inten-

ded to provide optimum conditions for cutting

with

CEDIMA

®

diamond saw blades.

Choose the correct type of saw blade for the ma-

terial to be cut and the required cutting depth.

(Ask

CEDIMA

®

customer service for detailed

information on the right type.)

Note:

No guarantee in case of incorrect use!

Where

CEDIMA

®

diamond saw blades have be-

en used incorrectly, the guarantee becomes inva-

lid. Complaints concerning diamond saw blades

can only be entertained if at least 20% of the

height of the diamond segments remains.

Note:

Resharpen blunt saw blades!

Diamond saw blades are designed to be self-

sharpening in operation. However, they can be-

come blunt through frequent cutting in hard ma-

terial that is only slightly abrasive. Blades can be

resharpened by cutting in an abrasive material

such as chalky sandstone.

3.6.2 Installing the saw blade

To install the saw blade, proceed as follows:

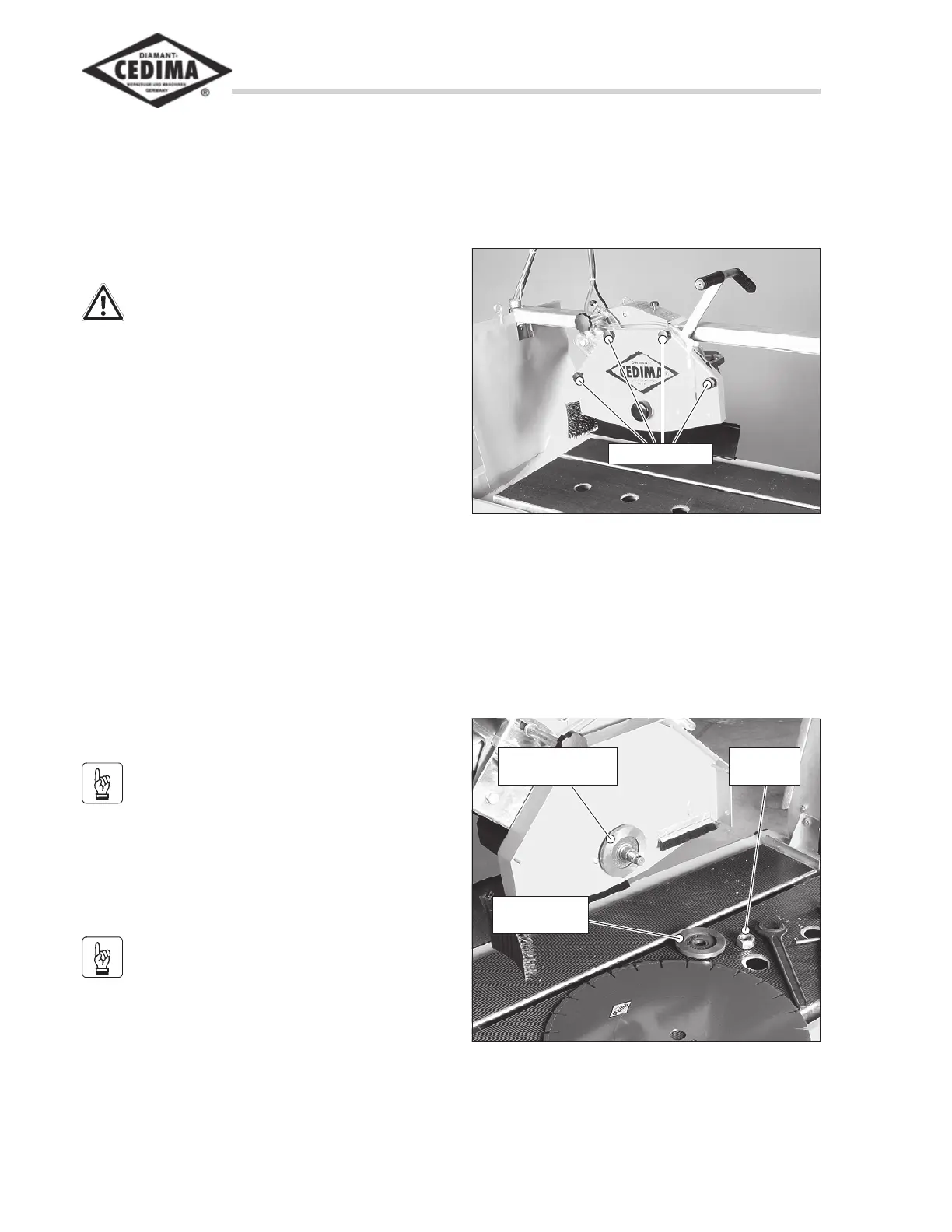

1. Loosen the knurled nuts (fig. 3.10) securing

the blade guard and remove the guard.

Fig. 3.10 Knurled nuts securing the blade guard

Knurled nuts

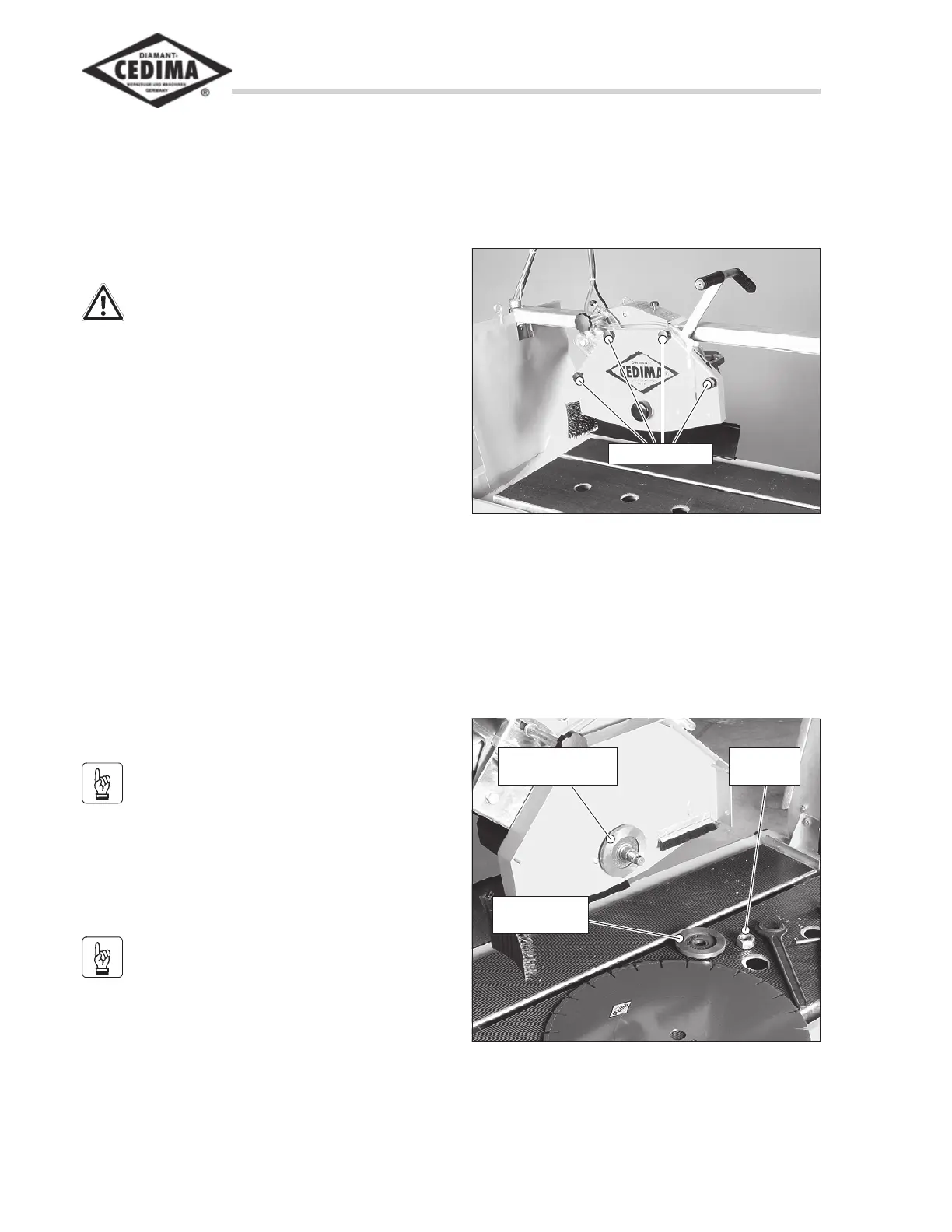

2. Loosen the cutting shaft nut from the blade

clamping flange using the open-jawed span-

ner and mandrel that come with the machine

(left-hand thread!)

3. Remove the blade clamping flange (fig.

3.11).

Fig. 3.11 Blade guard removed

Blade supporting

flange

Blade clam-

ping flange

Cutting

shaft nut

Loading...

Loading...