34

9. Inductive and Transformer Coupled Load Guidelines

10. Communications Port (Modbus RTU/RS485)

The model C4 should not be used for Inductive or Transformer Coupled Loads. The model C4-IR is capable of be-

ing used for these types of loads. Please refer to the C4-IR Hardware Manual for more details.

A network typically has a Master that “manages” com-

munication by means of “commands,” and Slaves that

carry out these commands.

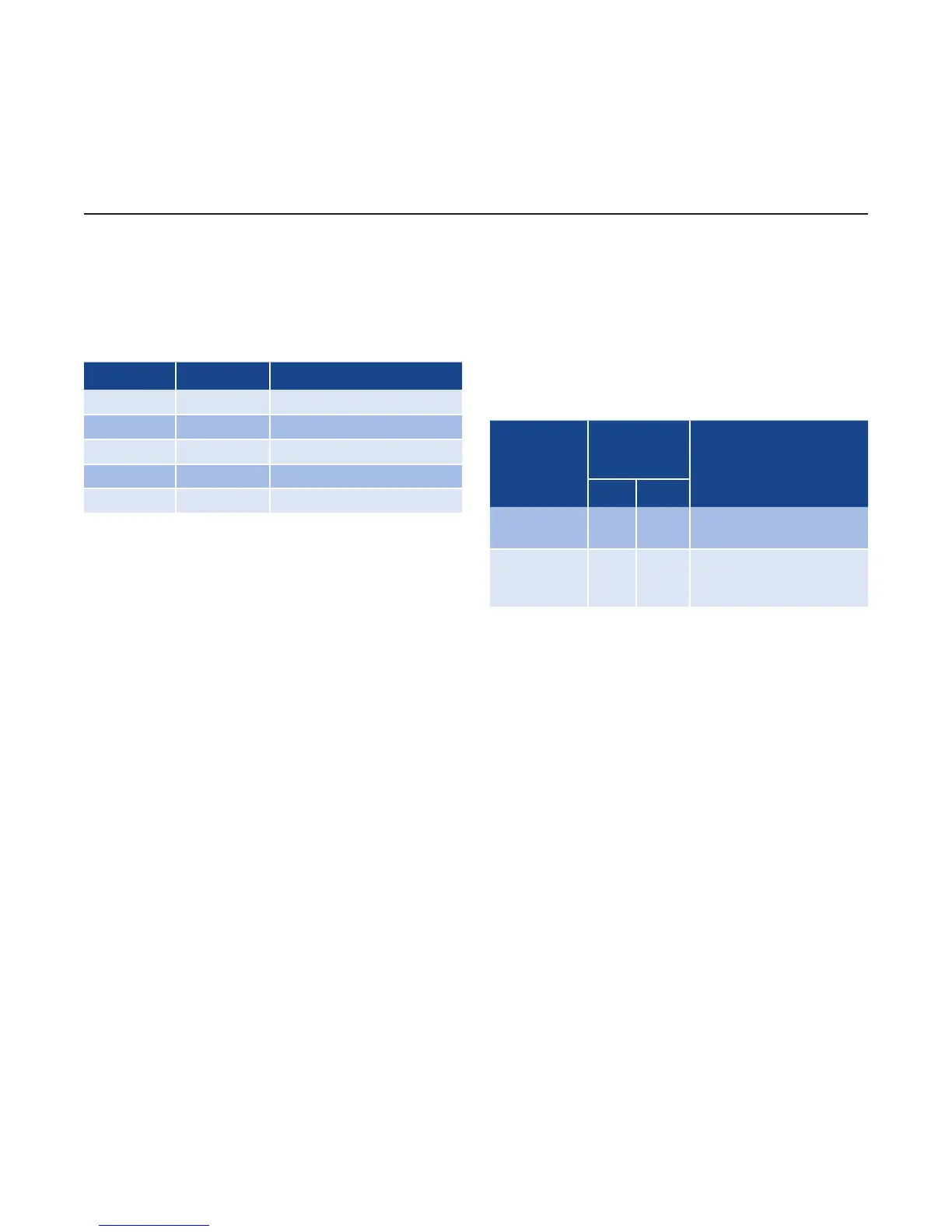

Parameter Default Range

ID 1 1...99

BaudRate 19.2kbits/s 1,2...57.6k bits/s

Parity None Parity/Odd Parity/None

StopBits 1 -

DataBits 8 -

C4 modules are considered Slaves to the network mas-

ter, which is usually a supervision terminal or a PLC.

They are positively identified by means of a node ad-

dress (ID) set on rotary switches (tens + units).

A maximum of 99 C4 modules can be installed in a se-

rial network, with node address selectable from “01”

to “99” in standard mode in which each C4 identifies

4 zones with sequential node address starting with the

code set on the rotary switches.

C4 modules have a ModBus serial (Serial 1) and, op-

tionally (see order code) a Fieldbus serial (Serial 2) with

one of the following protocols: Modbus RTU, Profibus

DP, CAN open, DeviceNet, and Ethernet Modbus TCP.

The ModBus RTU port 1 has the following factory set-

tings (default):

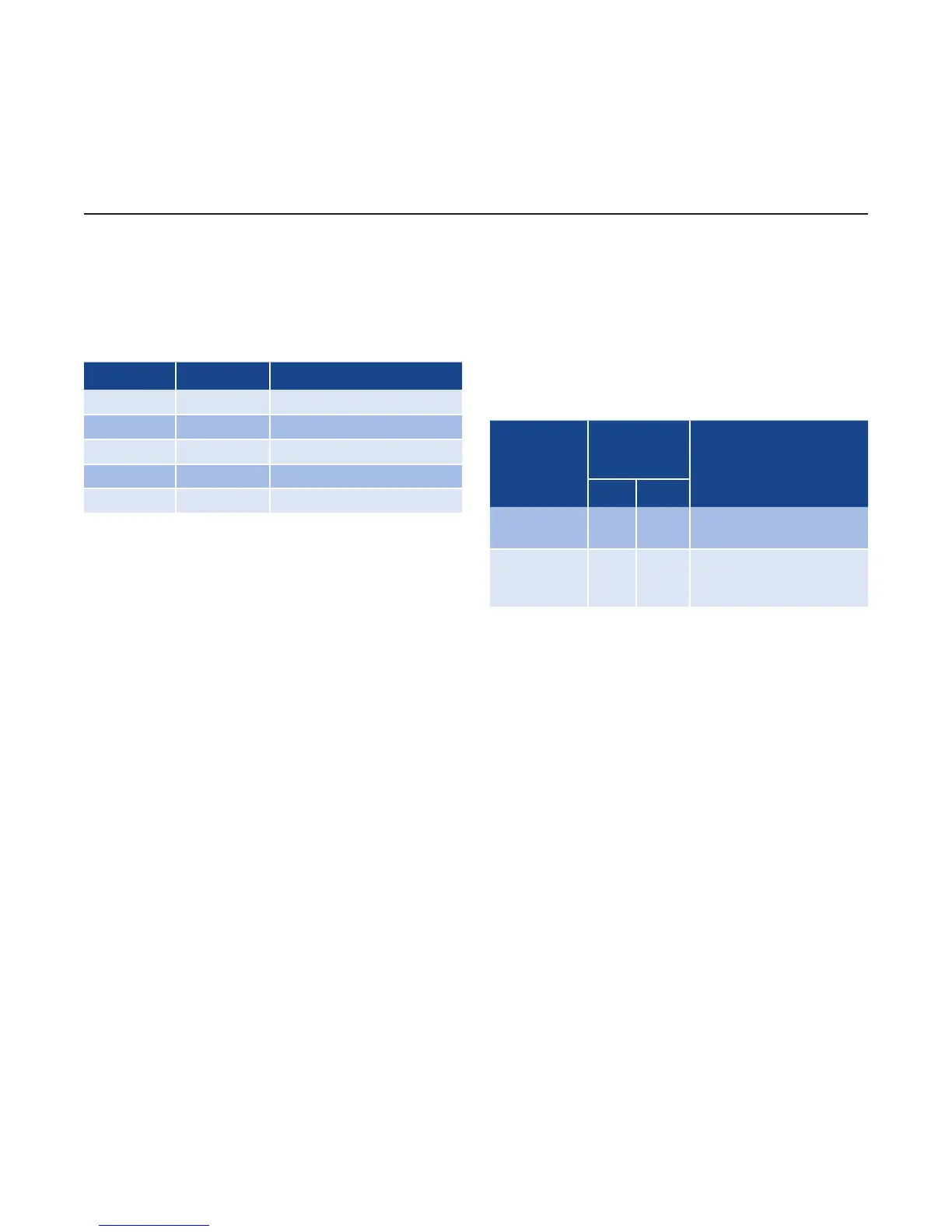

Procedures

Position of

Rotary

Switches

DescriptionTens Units

AutoBaud 0 0

It enables to set the

correct BaudRate Value

AutoNode* A 0

It enables to transfer

the correct node (ID)

address (tens)

The following procedures are indispensable for the

Modbus protocol. For the other protocols, see the spe-

cific manuals. The use of rotary switches (A...F) letters

is for particular procedures described in the following

paragraphs.

Loading...

Loading...