OPERATION 5-12 0-5461

Description Possible Cause Remedy

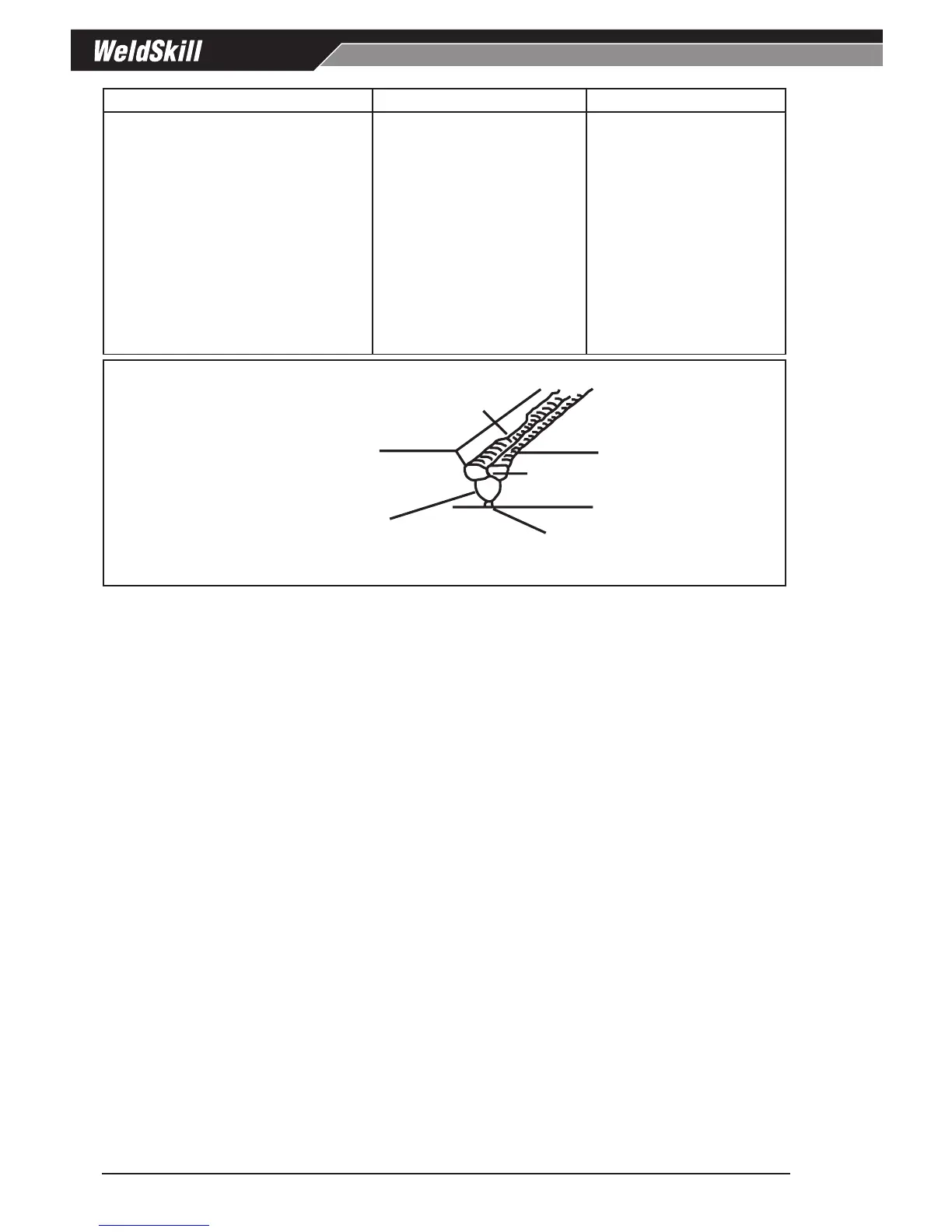

4 Portions of the weld run do not fuse

to the surface of the metal or edge of

the joint

A Small electrodes used on

heavy cold plate

A Use larger electrodes and

preheat the plate

B Welding current is too low B Increase welding current

C Wrong electrode angle C Adjust angle so the welding

arc is directed more into the

base metal

D Travel speed of electrode is

too high

D Reduce travel speed of

electrode

E Scale or dirt on joint surface E Clean surface before

welding

Art # A-05867_AC

Lack of

inter-

electrode angle incorrect,

rate of travel too high

Figure 5-30: Example of Lack of Fusion

Loading...

Loading...