0-5461 5-13 OPERATION

Description Possible Cause Remedy

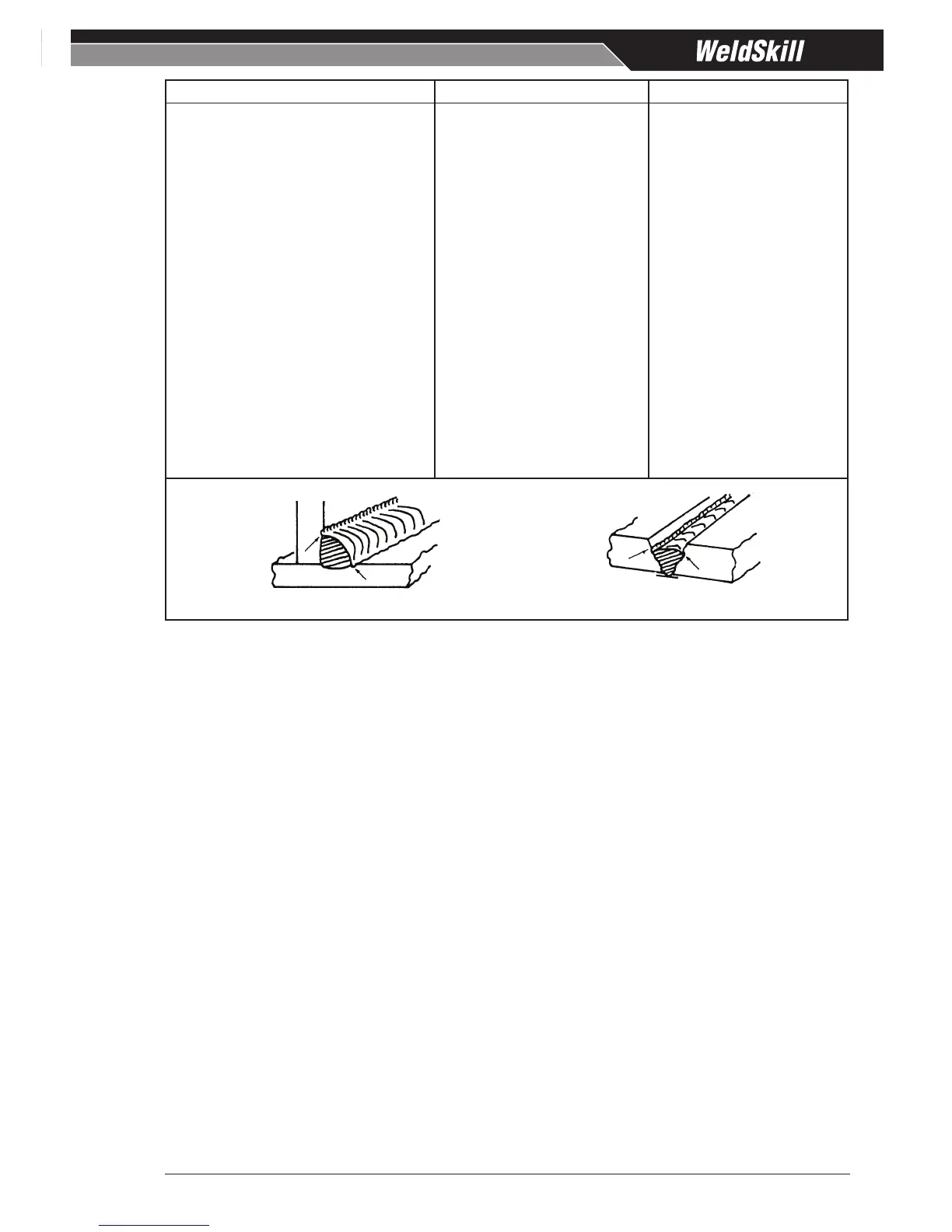

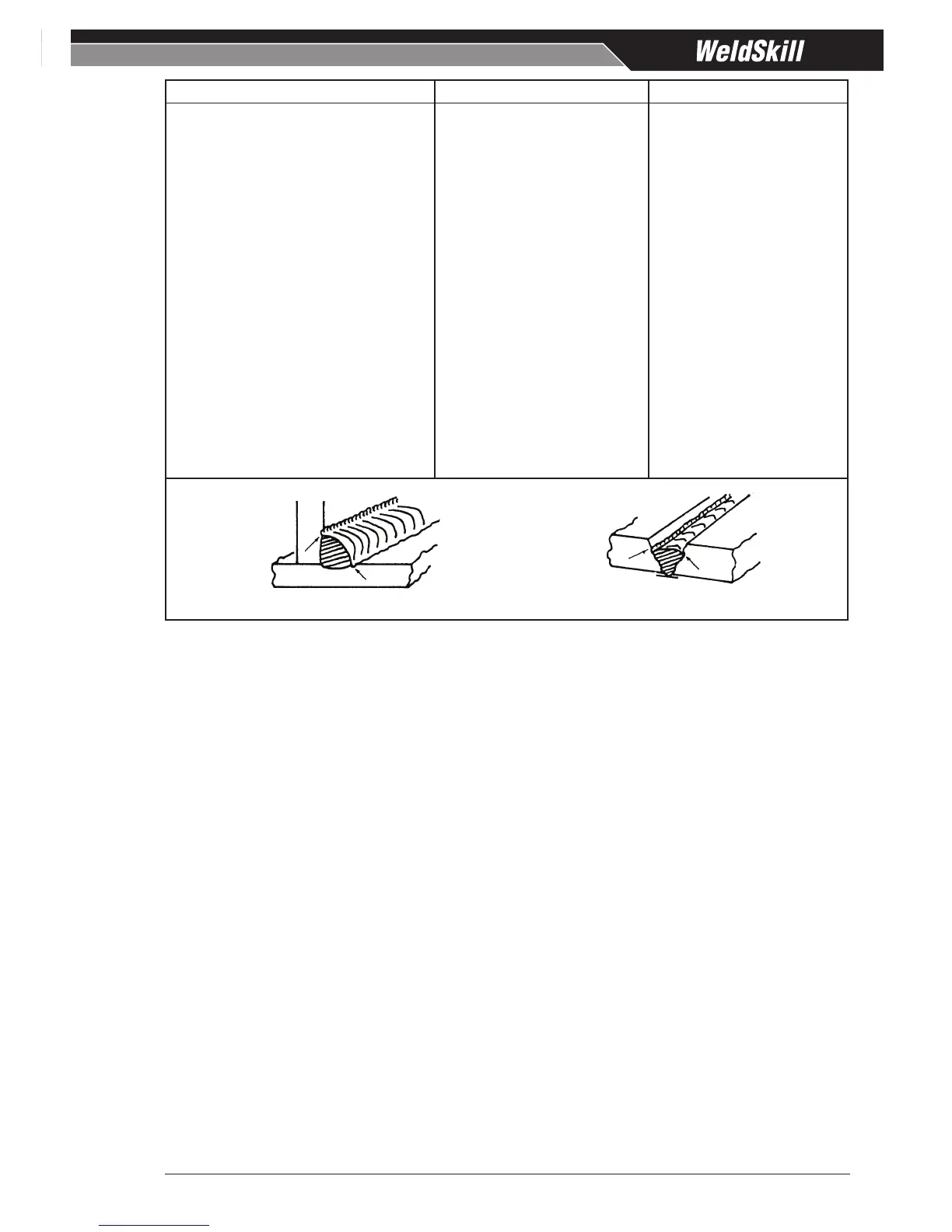

5 A groove has been formed in the base

metal adjacent to the toe of a weld

and has not been filled by the weld

metal (undercut).

A Welding current is too high. A Reduce welding current

B Welding arc is too long. B Reduce the length of the

welding arc

C Angle of the electrode is

incorrect.

C Electrode should not be

inclined less than 45° to the

vertical face

D Joint preparation does not

allow correct electrode angle.

D Allow more room in joint

for manipulation of the

electrode.

E Electrode too large for joint. E Use smaller gauge

electrode.

F Insufficient deposit time at

edge of weave.

F

Pause for a moment at

edge of weave to allow weld

metal build-up.

Art # A-07714

Figure 5-31: Examples of undercut

Loading...

Loading...