OPERATING INSTRUCTIONS

48

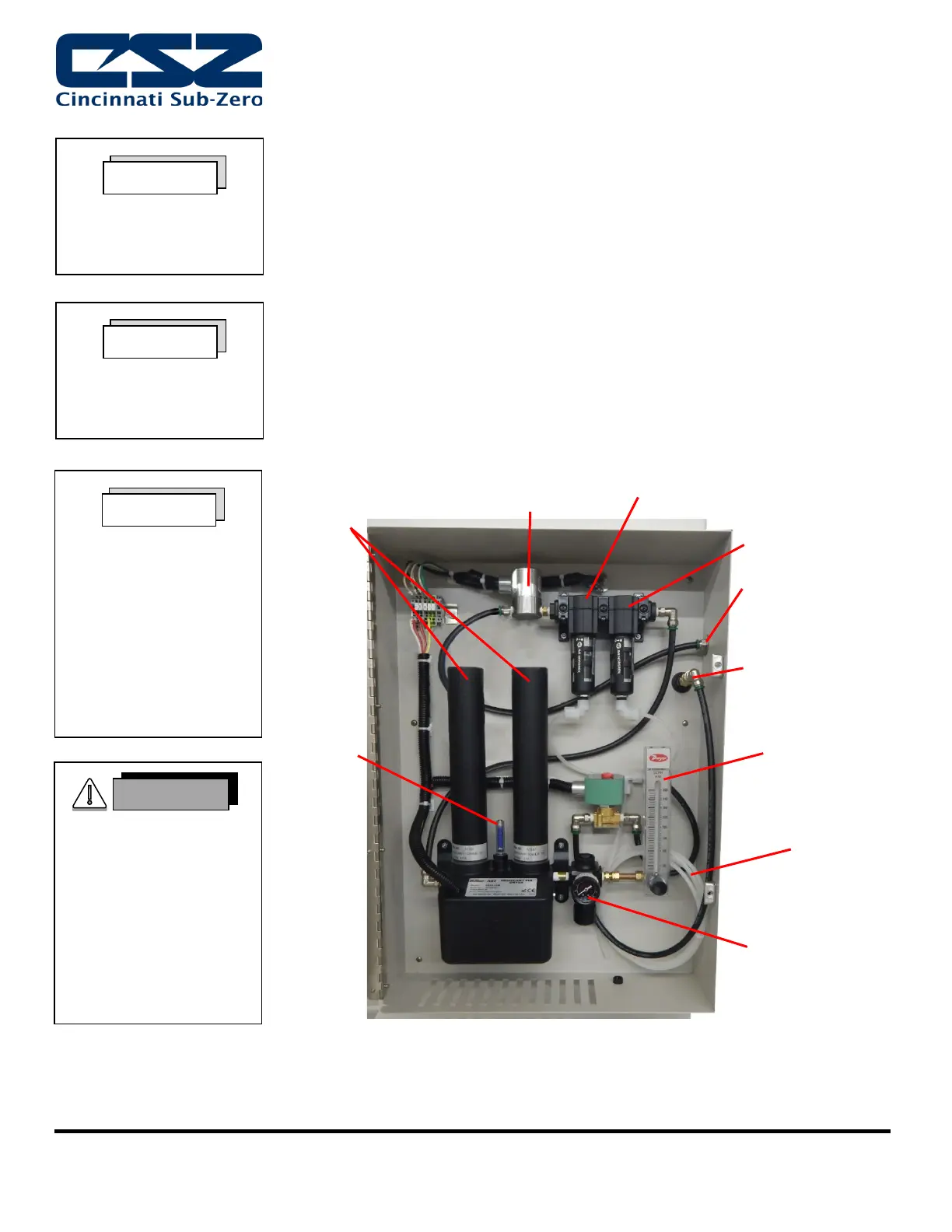

DRY AIR PURGE

In normal operation, the dryer towers will switch every 30 seconds. Each tower

purges with an audible exhaust. Do not plug or restrict the purge air exhausts.

If operating conditions change, different purge orifices may be required. If

orifices are replaced, they should be replaced in matched pairs.

The heat of absorption and the solenoid valves will cause the unit to become

warm. This is normal and does not indicate a malfunction. The temperature

rise is more pronounced in a dryer operating at a low flow rate.

During operation, there may be a faint fume from the solenoid valves. This is

caused by the AC voltage on the coil. It does not indicate a malfunction.

The highest ambient temperature at which a heatless dryer can be operated is

125°F (52°C). The maximum air temperature at the inlet which the instrument

should handle is 125°F (52°C).

Figure 3-3: Dry Air Purge System Components Location (5SCFM Unit)

Note: CSZ is continuously upgrading the components used in its equipment.

Consequently, the physical appearance of certain components may vary from that shown.

During humidity operation,

the dry air purge system

must be turned off.

mode for single set-point

operation.

SHOULD BE USED TO

SUPPLY THE DRY AIR

PURGE SYSTEM.

The Hose inside the dry air

purge package must be run

to a drain. Both oil and

water will be drained

through this line.

Do not expose the bowl or

sight glass to materials such

as carbon tetrachloride,

trichlorethylene, acetone,

paint thinner, or other

similar materials as they can

also cause a chemical

reaction with the plastic and

can cause it to rupture.

Valve-Solenoid,

Air Supply

to Chamber

Valve

Set at 150 SCFH

Hose

with Gauge Set at

80 PSIG (3.2

Loading...

Loading...