MAINTENANCE WITH Q & A

70

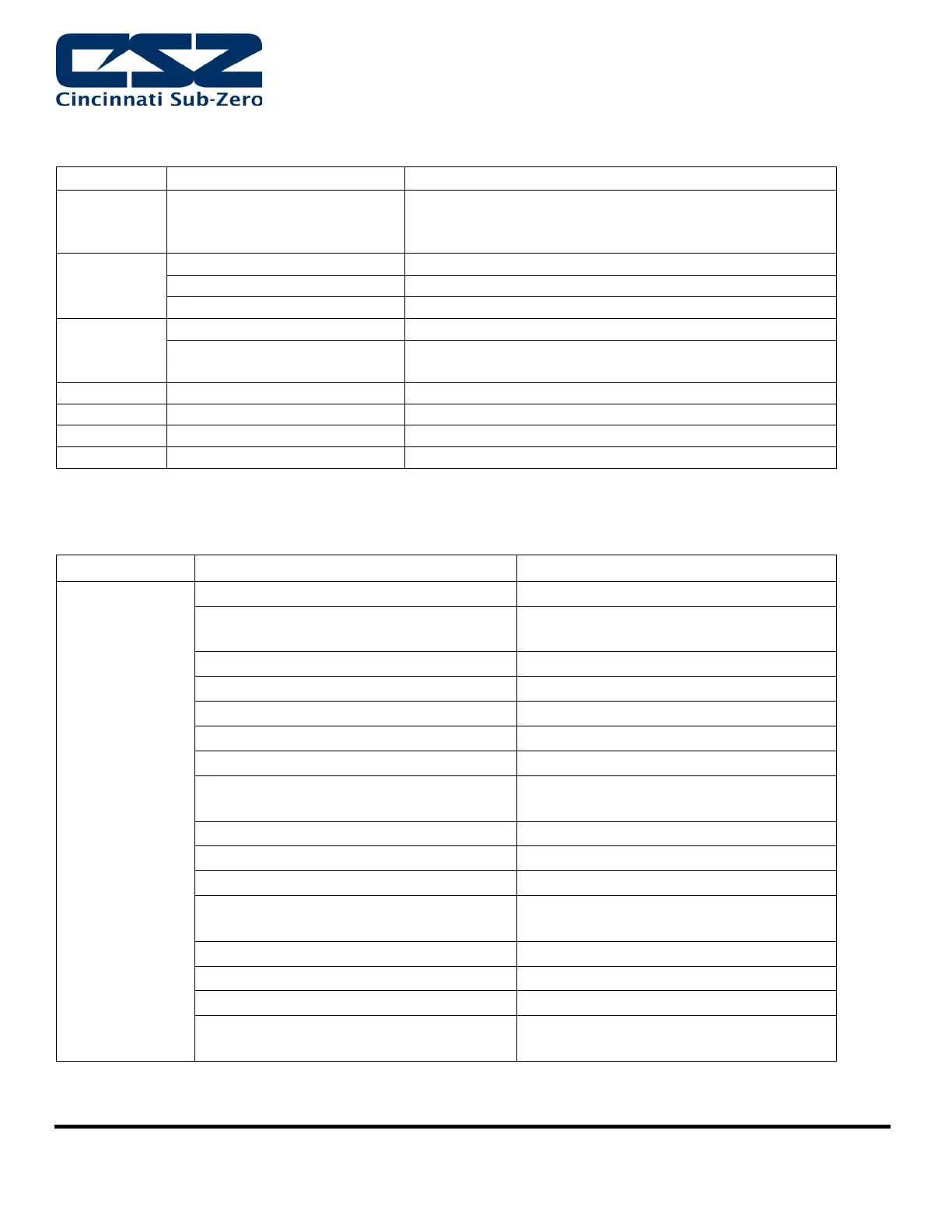

GENERAL TROUBLESHOOTING PROCEDURES

R-508B/R-23

head pressure

too low

R-404A head

pressure too

high

Maximum condenser inlet air = 80°F

Restricted air cooled condenser

Recover, evacuate and recharge

R-404A head

pressure too

low

Location may need to be changed

Insufficient compressor oil

Consult Cincinnati Sub Zero

Bend tubes away from contact

Compressor mounting loose

Table 5-4: General Troubleshooting Procedures (Continued)

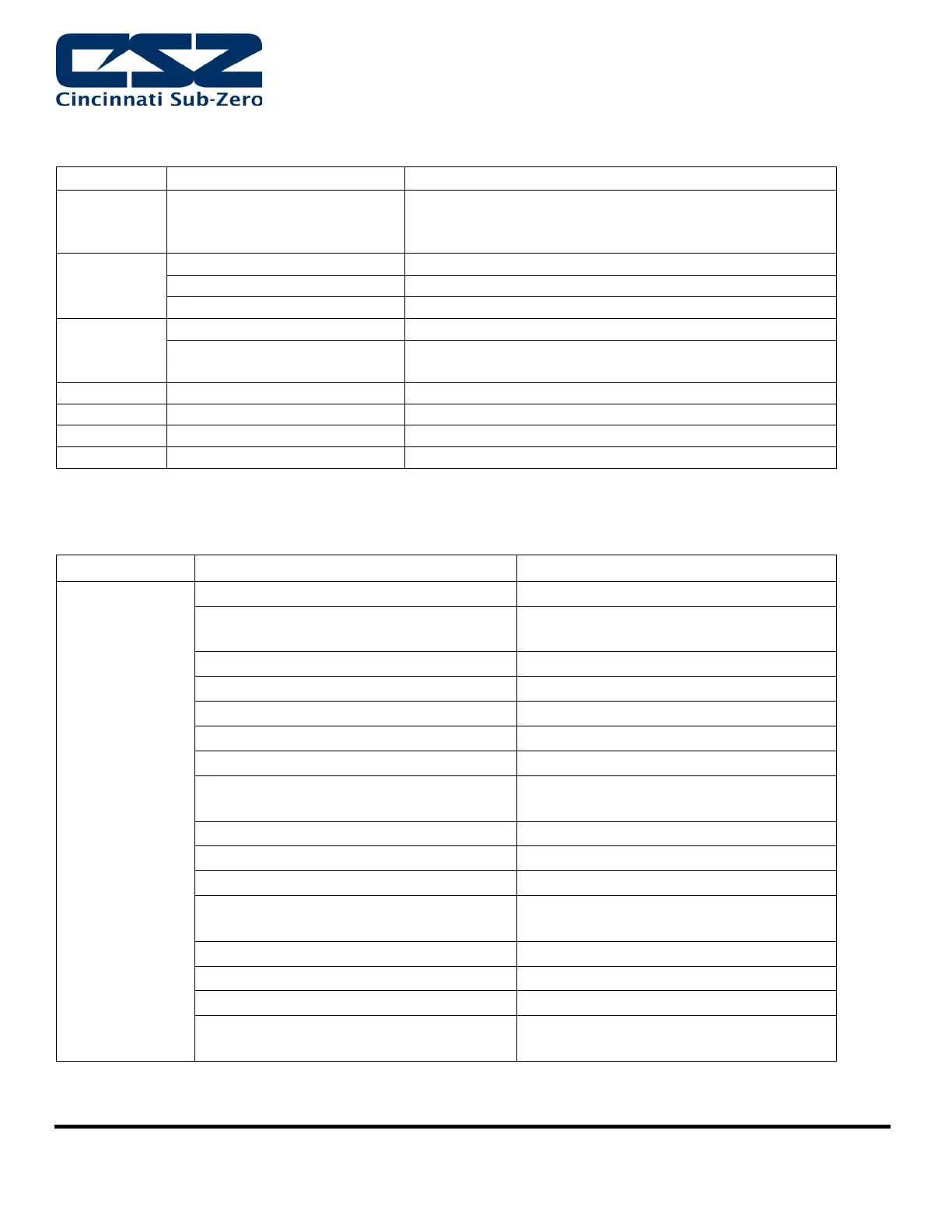

HUMIDITY TROUBLESHOOTING PROCEDURES (OPTIONAL ATOMIZER)

reaching desired

level

*Applies only to

units with an

atomizing

humidity system.

Check heater and replace as required

*Atomizing nozzle clogged

Remove and clean. Replace demineralizer

filter if necessary

Water is not connected to unit

Water control solenoid not energized

Check coil - replace if burned

Dispersion tube is clogged

Chamber fan not functioning

Check fan circuit check fan blade for

tightness on shaft

Demineralizer cartridge clogged internally

Solid state sensor defective

*Water metering valve not adjusting

properly

Adjust to 20.25 cubic centimeters

Defective heating element

See corresponding manufacturers manual

in the Accessories folder for information

Table 5-5: Humidity System Troubleshooting Procedures

Loading...

Loading...