41

Chapter 3 Printer Adjustments

Sensor Adjustments

Adjusting the Reective sensor

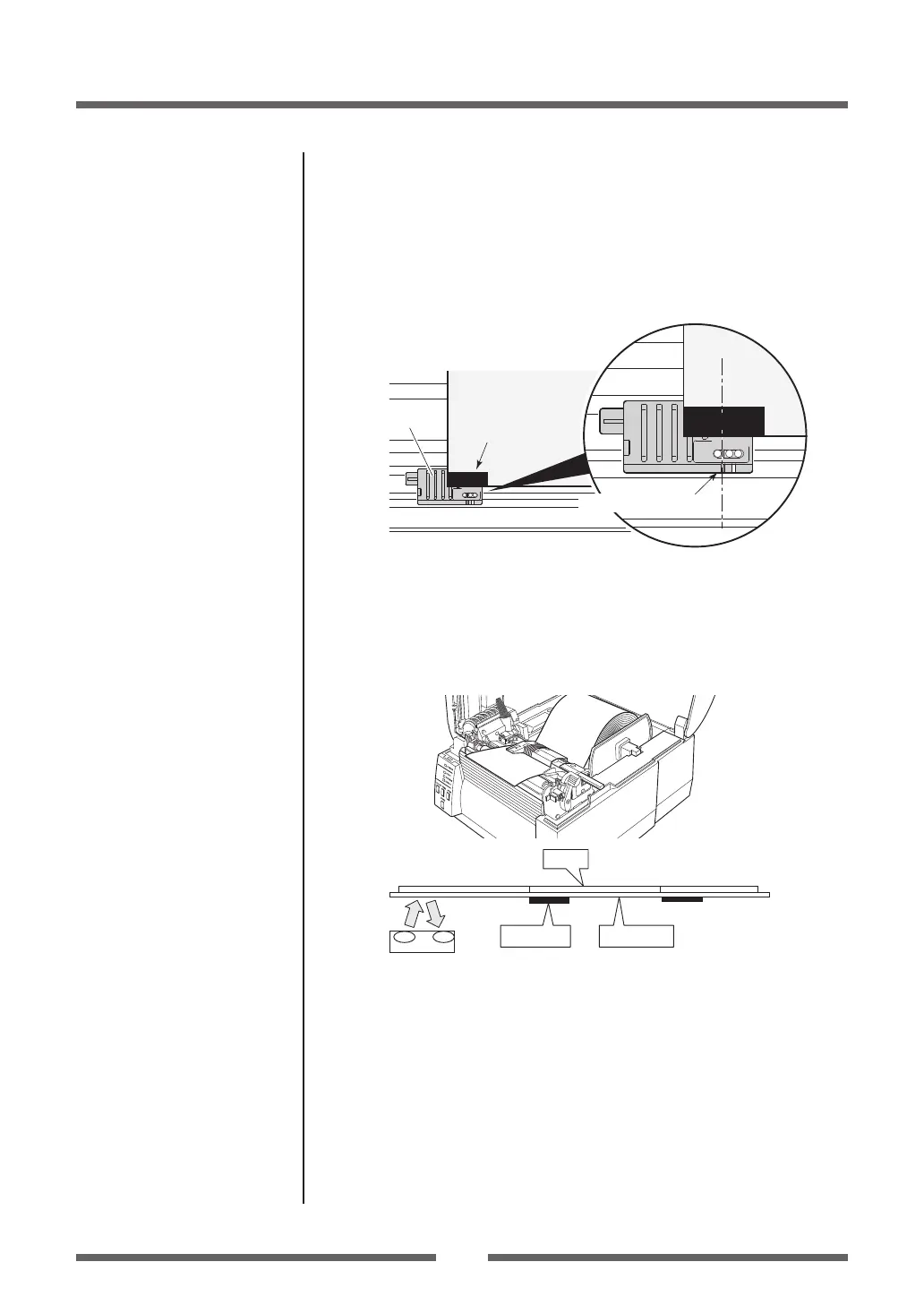

1. Open the printhead and the sensor arm, then align the

position of the sensor marker of the bottom sensor is at the

center of the black mark on the media.

Black mark

Media

Bottom sensor

Reective sensor marker

Black mark

2. Select the reective sensor.

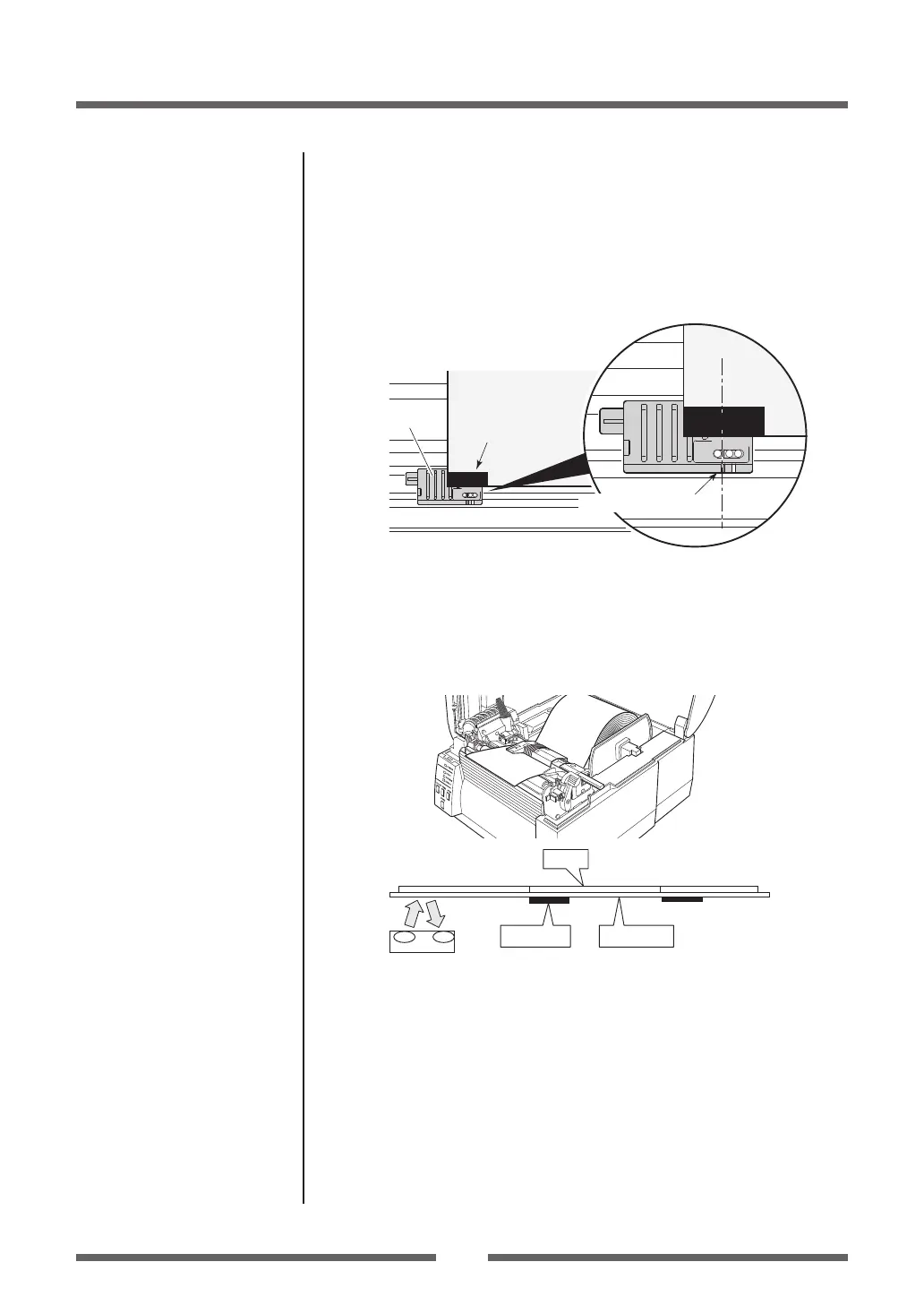

3. With the reective sensor selected, install the label media

so that it is between the platen roller and the media sensor.

(Be careful that black mark and media gap do not pass the

media sensor.) Then close the sensor arm and the printhead.

Black mark

Label

Liner media

Bottom sensor

4. If the PAUSE key is pressed and released while the MODE/

REPEAT key is pressed, PRINT LED goes o, the CONDITION

LED switches from lit to rapid ashing, media feeding starts,

and the sensor is automatically adjusted.

5. If automatic adjustment stops normally, the PRINT LED and

CONDITION LED return to their original status. If it does not

stop normally (adjustment impossible), the CONDITION LED

and ERROR LED ash.

6. If the STOP key is pushed, it exits sensor adjustment mode.

Sensor Selection Method

(Transparent

Reective) (p.39)

Loading...

Loading...