SM-A20758-A/3 7. References

63 2020-10-06

◼ EVD-3000

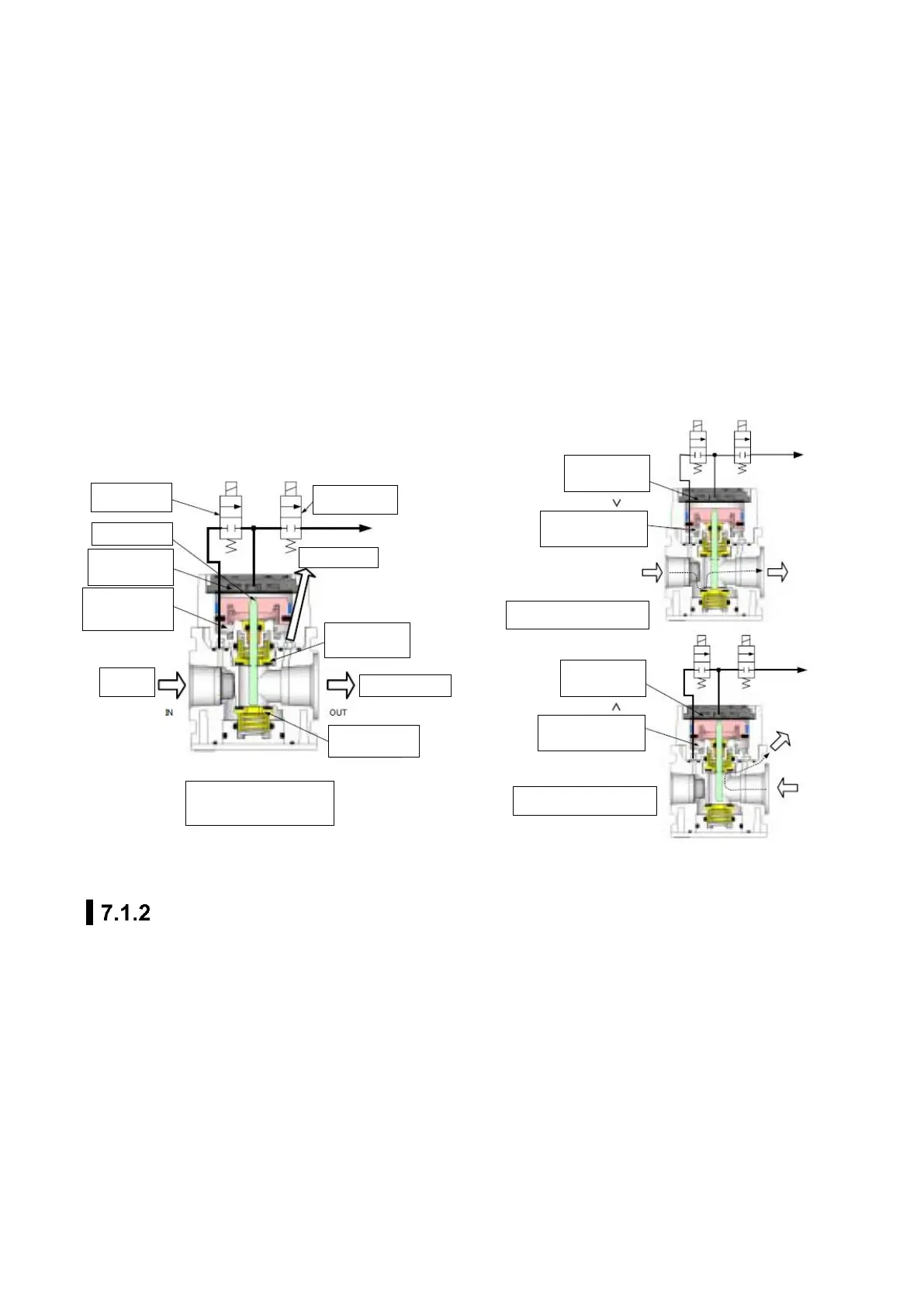

The EVD-3000 series includes the pilot control section described above and a booster section for

improving flow characteristics. The booster section includes an air supply valve (top valve), an exhaust

valve (bottom valve), and a piston assembly to open and close them. The exhaust valve is connected to

the piston assembly.

The lower chamber of the piston assembly has the same pressure as the controlled pressure. The upper

chamber controls the pilot pressure by PWM-driving the solenoid valve. This difference in pressure

moves the piston assembly up and down to open and close the valve.

The EVD-3000 series senses the controlled pressure with a pressure sensor to constantly adjust the

pilot pressure as follows for high-precision pressure control:

When the controlled pressure is lower than the set pressure, that is, the controlled pressure is to be

boosted, the pilot pressure is controlled to achieve the following state:

Upper chamber pressure (pilot pressure) > Lower chamber pressure (controlled pressure)

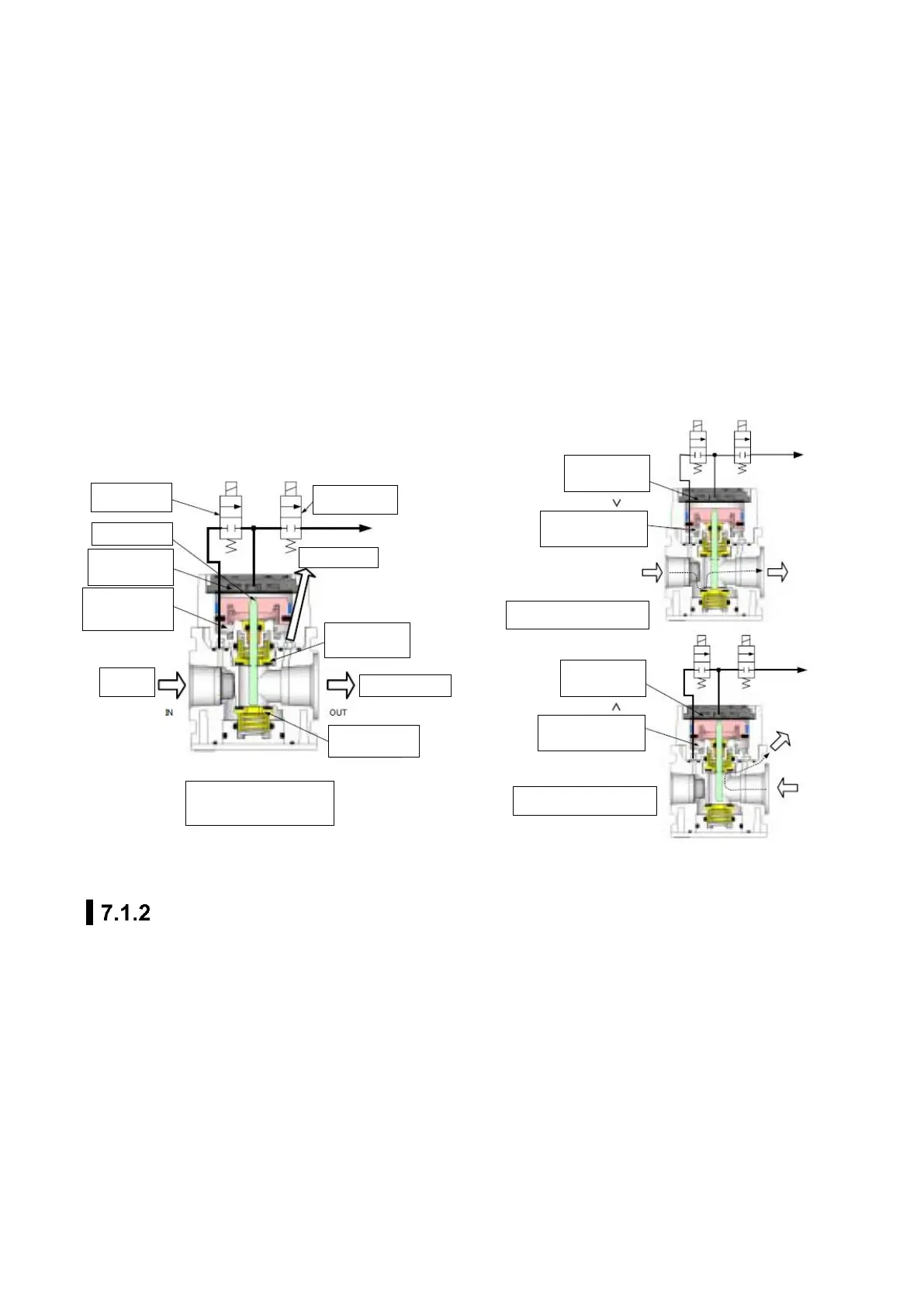

When the controlled pressure is higher than the set pressure, that is, the controlled pressure is to be

reduced, the pilot pressure is controlled to achieve the following state:

Upper chamber pressure (pilot pressure) < Lower chamber pressure (controlled pressure)

About overactive state

Definition of overactive state: The overactive state is defined as a state in which the solenoid valve

continues to turn ON and OFF repeatedly like the patterns B and C as shown in "・Pressure control

diagram" above.

A continuous ON time like the pattern A or an extremely short ON time like the pattern D will not cause

the overactive state.

If this overactive state continues for a long time, the life of the solenoid valve will be greatly affected.

Loading...

Loading...