WS1CS & WS1.25CS Manual Page 5

Table 4 shows the order of the cycles when the

valve is set up as a fi lter. If the control valve is set

to regenerate for a fi lter, the OEM has the option

of having the regenerant refi ll after the rinse cycle

or have the regenerant prefi ll before regeneration.

If the OEM chooses to have the regenerant prefi ll

before regeneration, the prefi ll starts two hours

before the regeneration time set. During the

2-hour period in which the regenerant is being

made, treated water is still available. For example:

regeneration time = 2:00 am, prefi ll option

selected, downfl ow fi lter. Fill occurs at 12:00 a.m.,

start of backwash cycle occurs at 2:00 a.m.

When the control valve is used as a non-

regenerating fi lter, the OEM has the option to

specify one backwash or two backwashes. If two

backwashes are specifi ed, two rinses occur. Tables

5 and 6 show the length of the cycles when the

valve is set up as a fi lter. When used as a non-

regenerating fi lter, the downfl ow piston must be

installed, the regenerant piston removed, injector

plugs must be installed in both the DN and UP

injector locations and the refi ll elbow must be

replaced with a refi ll port plug.

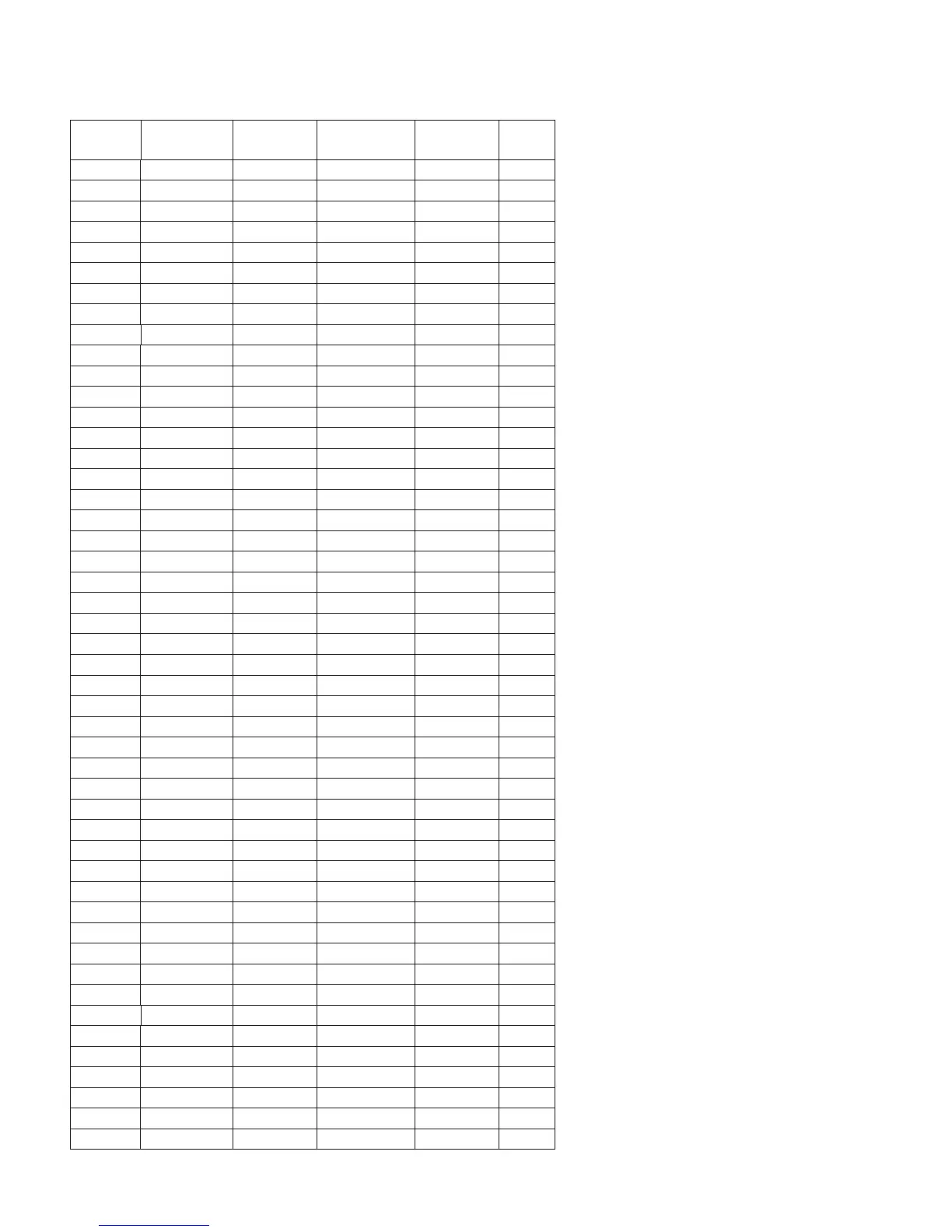

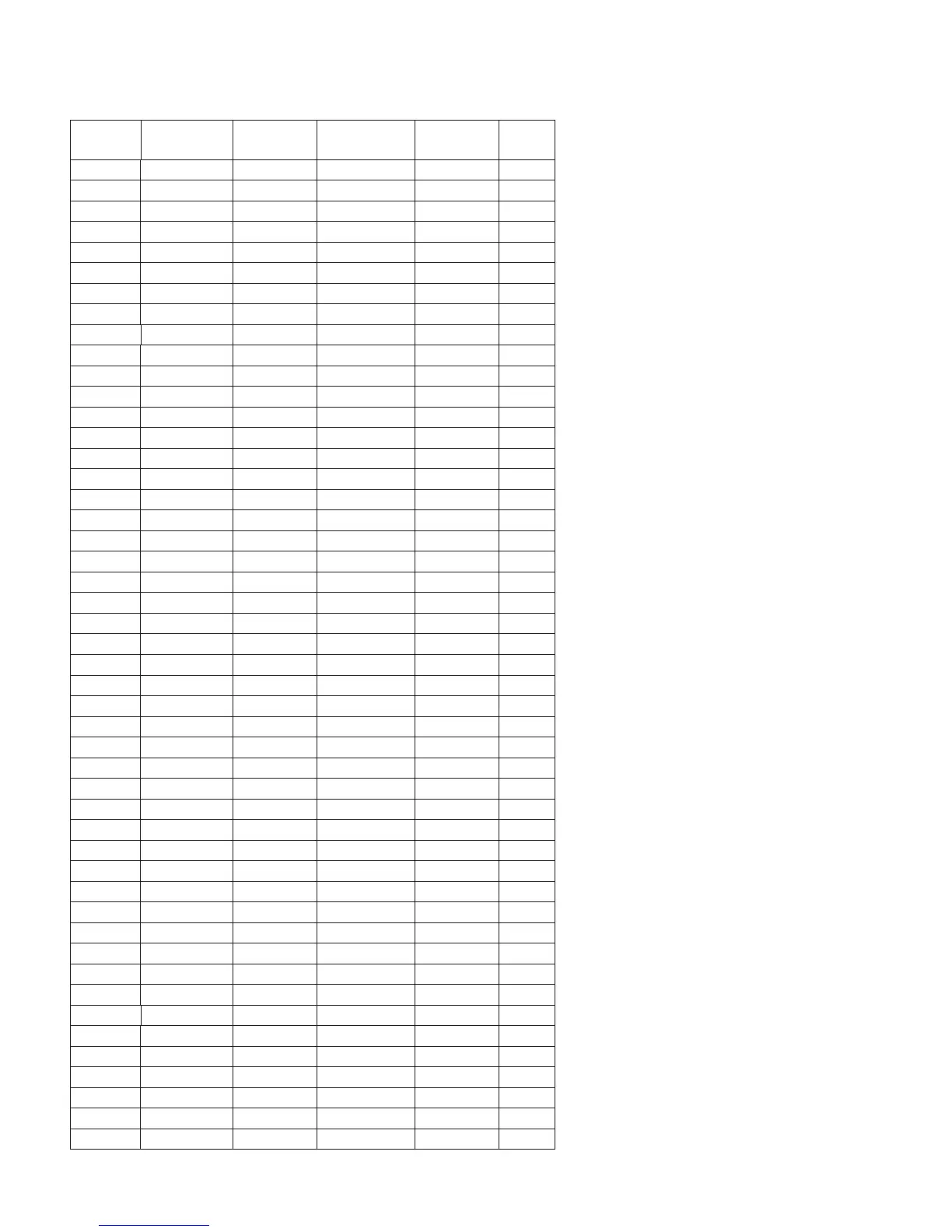

NOTE: The program codes listed on this page

and the following page should be used only as a

guideline. Any program code listed can be applied

to a softener or fi lter application for WS1CS

valves.

Program

Code

Main Piston

1

st

Backwash

Brine/Slow

Rinse

2

nd

Backwash

Fast

Rinse

P1 Down Flow 3 40 3 3

P2 Down Flow 3 45 3 3

P3 Down Flow 4 45 4 3

P4 Down Flow 4 60 4 3

P5 Down Flow 5 60 4 4

P6 Down Flow 5 60 5 4

P7 Down Flow 6 45 4 3

P8 Down Flow 6 60 5 4

P9 Down Flow 6 60 6 5

P10 Down Flow 7 50 5 4

P11 Down Flow 7 60 6 6

P12 Down Flow 7 65 7 7

P13 Down Flow 8 45 5 4

P14 Down Flow 8 60 6 6

P15 Down Flow 8 60 8 8

P16 Down Flow 8 65 8 6

P17 Down Flow 8 65 8 7

P18 Down Flow 8 75 8 5

P19 Down Flow 9 50 5 5

P20 Down Flow 9 60 5 4

P21 Down Flow 9 65 8 5

P22 Down Flow 10 45 4 4

P23 Down Flow 10 60 5 4

P24 Down Flow 10 65 8 8

P25 Down Flow 10 65 6 5

P26 Down Flow 10 75 7 5

P27 Down Flow 12 45 4 4

P28 Down Flow 12 60 6 4

P29 Down Flow 12 60 8 8

P30 Down Flow 12 65 6 6

P31 Down Flow 12 65 8 8

P32 Down Flow 12 65 12 8

P33 Down Flow 12 75 6 6

P34 Down Flow 14 45 5 4

P35 Down Flow 14 60 6 5

P36 Down Flow 14 60 8 8

P37 Down Flow 14 65 7 6

P38 Down Flow 14 65 8 8

P39 Down Flow 14 65 12 8

P40 Down Flow 14 75 8 7

P41 Down Flow 16 60 7 5

P42 Down Flow 16 65 8 6

P43 Down Flow 16 65 8 8

P44 Down Flow 16 65 12 8

P45 Down Flow 16 75 9 7

P50 Down Flow 6 45 3 3

P51 Down Flow 8 60 8 4

P52 Down Flow 8 75 10 6

Table 2

Downfl ow Softener Program Codes for WS1CS or WS1.25CS

Loading...

Loading...