07610-004-64-85-A

16

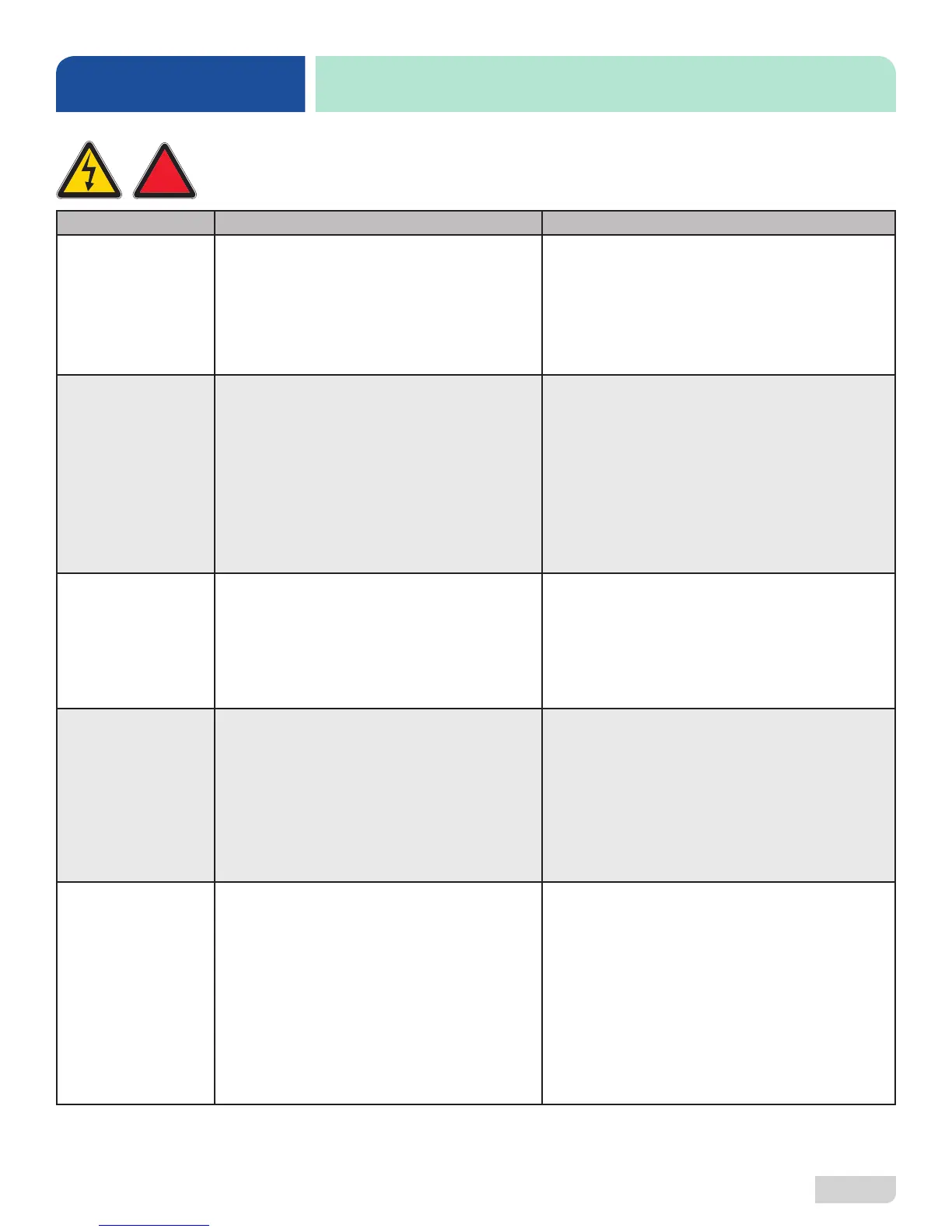

TROUBLESHOOTING

TROUBLESHOOTING

OBSERVATION POSSIBLE CAUSE REMEDY

A. Power light not

illuminating.

1. Power disconnect "OFF."

2. Power disconnect or fuses burned out.

3. Power light damaged.

4. Power button damaged.

1. Flip power disconnect to "ON."

2. Contact qualied service agency.

3. Contact qualied service agency.

4. Contact qualied service agency.

B. Machine not

lling.

1. Water inlet interceptor shutter down.

2. Standpipe not seated.

3. Inlet solenoid valve lter clogged.

4. Inlet solenoid valve coil disconnected.

5. Inlet pipe lter clogged.

6. Faulty PCB.

1. Open the shutter.

2. Fit the overow properly into the drain.

3. Clean the solenoid valve lter.

4. Contact qualied service agency.

5. Clean the inlet hose lter.

6. Replace.

C. Machine keeps

lling after water

level is reached.

1. Solenoid valve membranes damaged.

2. Solenoid valve membranes dirty.

1. Contact qualied service agency.

2. Contact qualied service agency.

D. Wash ineective.

1. Detergent ineectual/unsuitable.

2. Detergent incorrectly dosed.

3. Suction lter dirty.

4. Too much foam in the tank.

5. Wash arms do not rotate freely.

1. Change detergent.

2. Increase detergent dose.

3. Clean the lter.

4. Decrease detergent dose.

5. Clean wash arms and bushings.

E. Rinse inadequate.

1. Water pressure below requirement.

2. Nozzles clogged with lime deposits.

3. Solenoid valve lter clogged.

4. Rinse solenoid valve coil disconnected.

5. Inlet hose lter dirty.

6. Lime deposits in the booster.

7. Rinse arms do not rotate freely.

1. Adjust water pressure to meet requirement.

2. Perform deliming operation.

3. Clean the lter.

4. Contact qualied service agency.

5. Clean the lter.

6. Contact qualied service agency.

7. Clean rinse arms and bushings.

WARNING! Inspection, testing, and repair of electrical equipment should only be performed by a

qualied service technician. Many of the tests require that the machine have power to it and live

electrical components be exposed. USE EXTREME CAUTION WHEN TESTING THE MACHINE.

!

WARNING

Loading...

Loading...