16

P/N 192047138 Rev AA November 2017

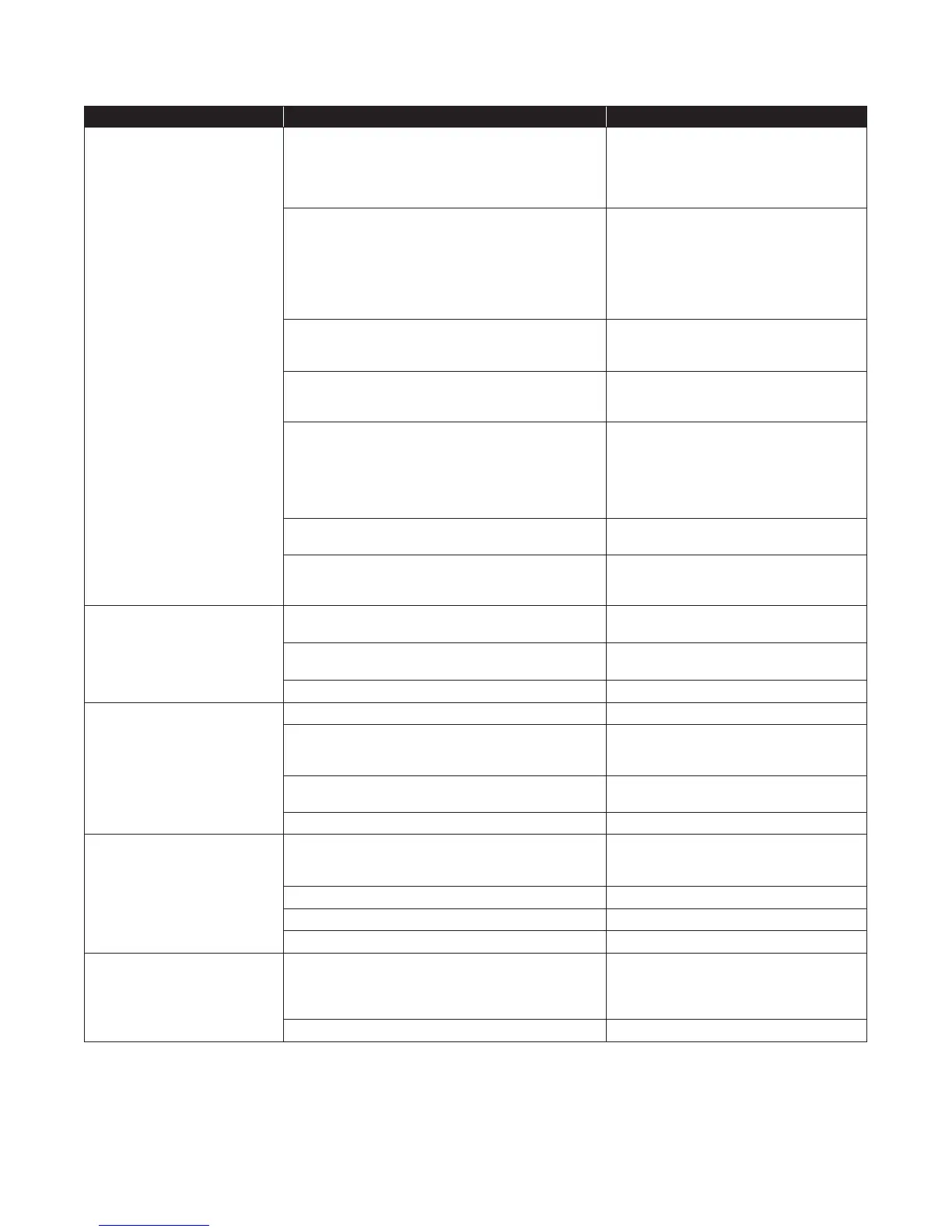

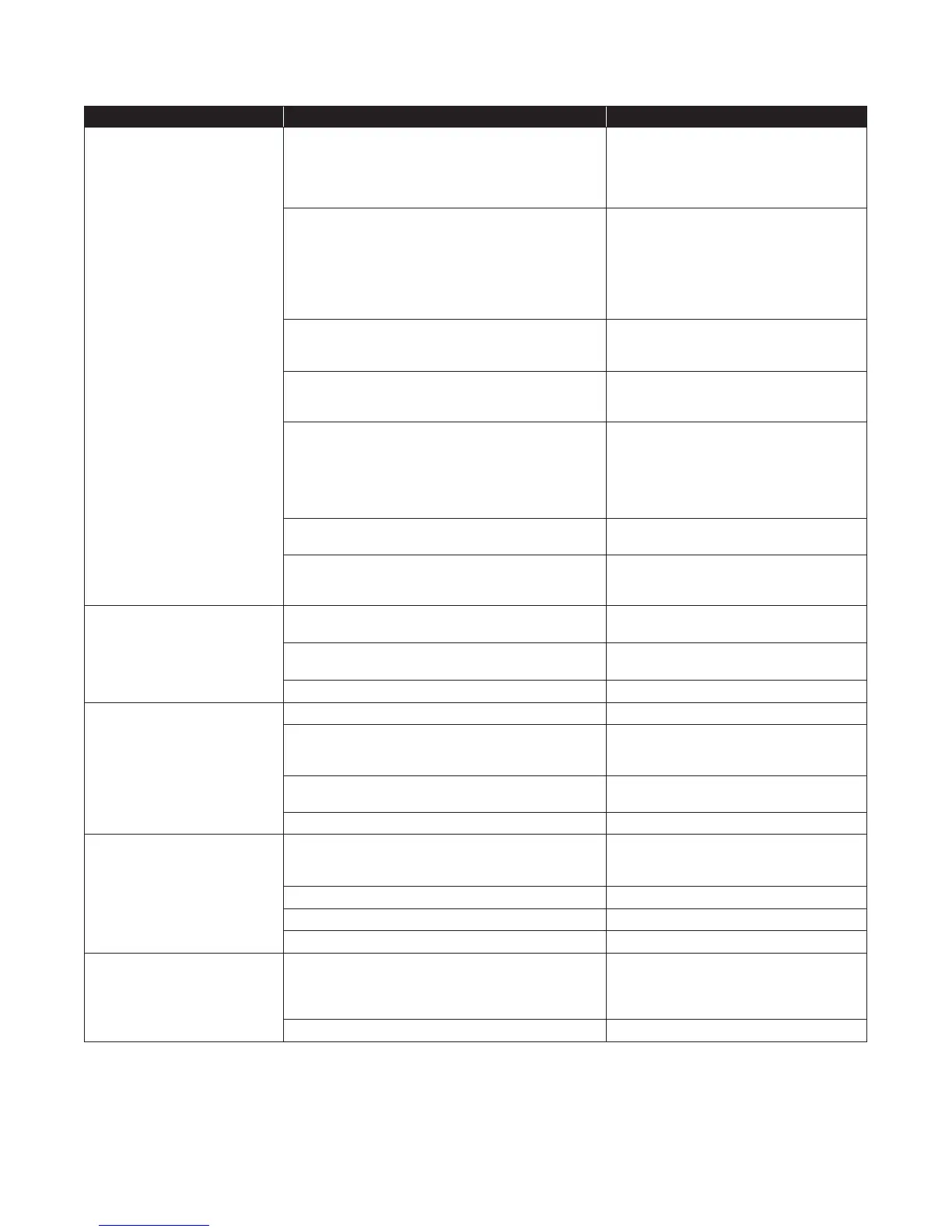

TROUBLESHOOTING CHART

Always disconnect unit from the power supply system before removing hoist covers or the back cover of control station.

Symptom Possible Cause(s) Corrective Action

1. Hook does not respond to the control

station

A.) No voltage at hoist-main line or branch circuit switch open;

branch line fuse blown or circuit breaker tripped.

A.) Check for blown fuse or tripped circuit breaker

or open disconnect switch in main line or branch

circuit. Replace fuse, reset circuit breaker or

close switch.

B.) Open control circuit due to loose connections or broken wires in

circuit; motor thermal protector open; control station contacts

not closing; open or Shorted winding in transformer; transformer

thermal cut-out open; mechanical binding in contactor; open

or shorted winding in contactor coil or blown Printed Circuit

Board fuse.

B.) Check electrical continuity thru motor thermal

protector. If it is open, allow motor to cool. If this

does not correct the trouble, use wiring diagram to

check electrical continuity of wiring, transformer,

contactor and control station contacts. Repair

wiring or replace defective part. Check Printed

Circuit Board fuse & replace if needed.

C.) Wrong voltage or frequency. C.) Make sure that the power supply to hoist is the

same as that shown on identification plate on

button of hoist.

D.) Low Voltage. D.) Check power supply system to make sure it

complies with the requirements listed under

“power supply system” starting on page 3.

E.) Brake not releasing due to open or shorted coil, defective diodes

or brake disc binding.

E.) Check coil continuity, diodes and connections.

Make sure brake disc slides freely on brake driver

and brake spring is not broken. Replace coil (brake

field), repair connections, remove burrs from

brake driver so that brake disc slides freely and/or

replace brake spring.

F.) Excessive load. F.) Reduce load to capacity limit as indicated on

identification and capacity labels on hoist.

G.) Phase failure (single phasing-three phase units only) - open circuit,

grounded or faulty connection in one line of power supply system,

hoist wiring, contactor, motor leads or windings.

G.) Check for electrical continuity and repair or

replace defective part.

2.) Hook moves in the wrong direction. A.) Wiring connections reversed in control station or hoist. A.)Use wiring diagram and check wiring connections.

B.) Failure of cut-out device (single phase units only) to effect

dynamic braking at time of reversal.

B.) Check connections to cut-out device. Replace

damaged device or faulty capacitor

C.) Phase reversal (three phase unit only). C.) See “Three Phase Hoists.”

3.) Hook lowers but will not raise. A.) Excessive load. A.) See item 1F.

B.) Hoisting circuit is OPEN due to loose connections or broken

wire in circuit; control station contacts are not making; open or

shorted winding in contactor coil.

B.) Use wiring diagram to check electrical continuity

of wiring and control station contacts. Repair wiring

or replace defective part.

C.) Motor cut-out device not operating. (single phase units only). C.) Check cut-out device and connections to same.

Repair connections and/or replace cut-out device.

D.) Phase failure (three phase units only). D.) See item 1G.

4.) Hook raises but will not lower. A.) Lowering circuit is OPEN due to loose connections or broken

wire; control station contacts not closing; open or shorted

winding in contactor coil.

A.) See item 1B.

B.) Motor reversing switch not operating (single phase unit only). B.) See item 3C

C.) Phase reversal (three phase units only). C.) See item 2C

D.) Phase failure (three phase units only). D.) See item 1G.

5.) Hook does not stop promptly. A.) Brake slipping. A.) Check electric brake, especially the brake disc for

wear or glazing and make sure brake spring is not

broken. Replace worn or glazed brake disc or replace

brake spring.

B.) Excessive load. B.) See item 1F.

Loading...

Loading...