32

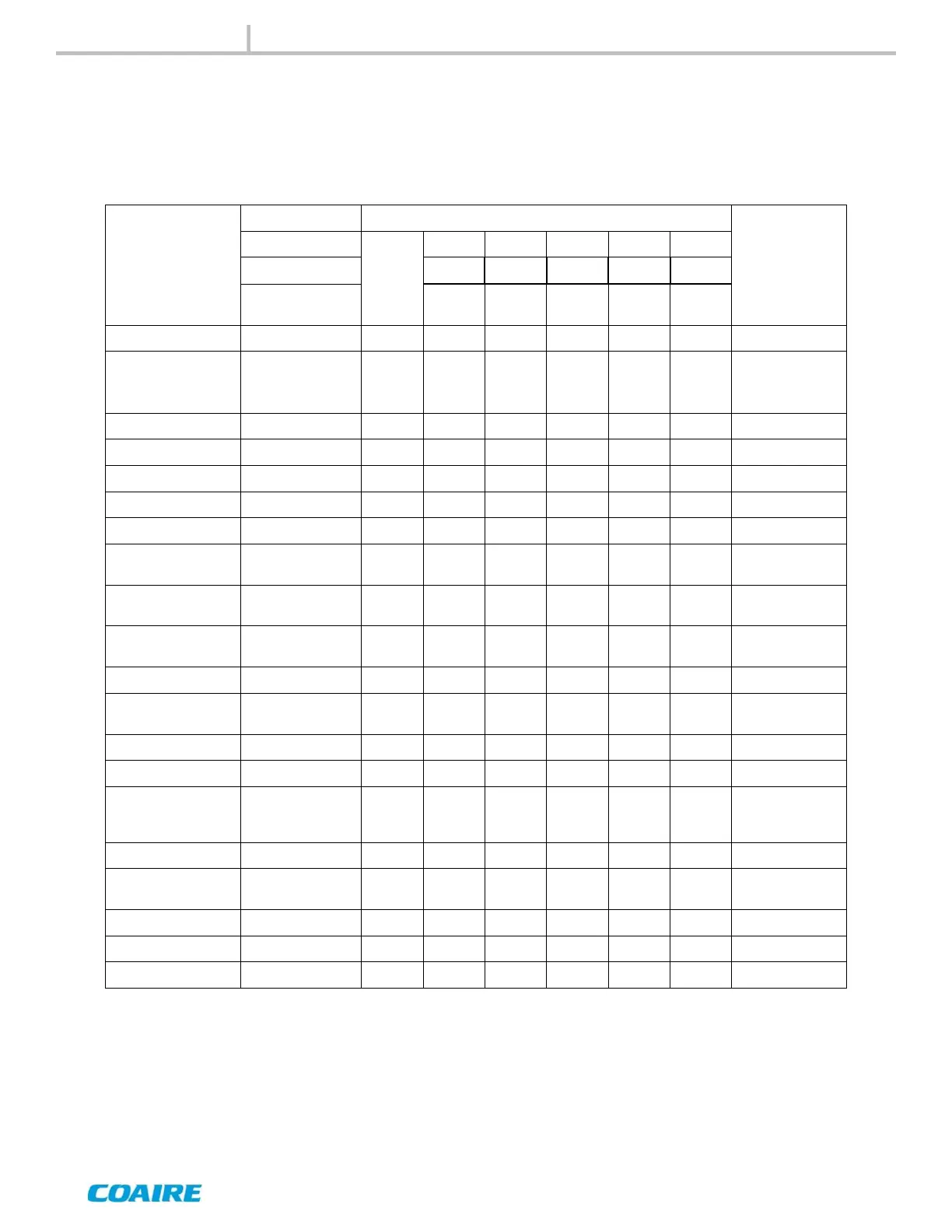

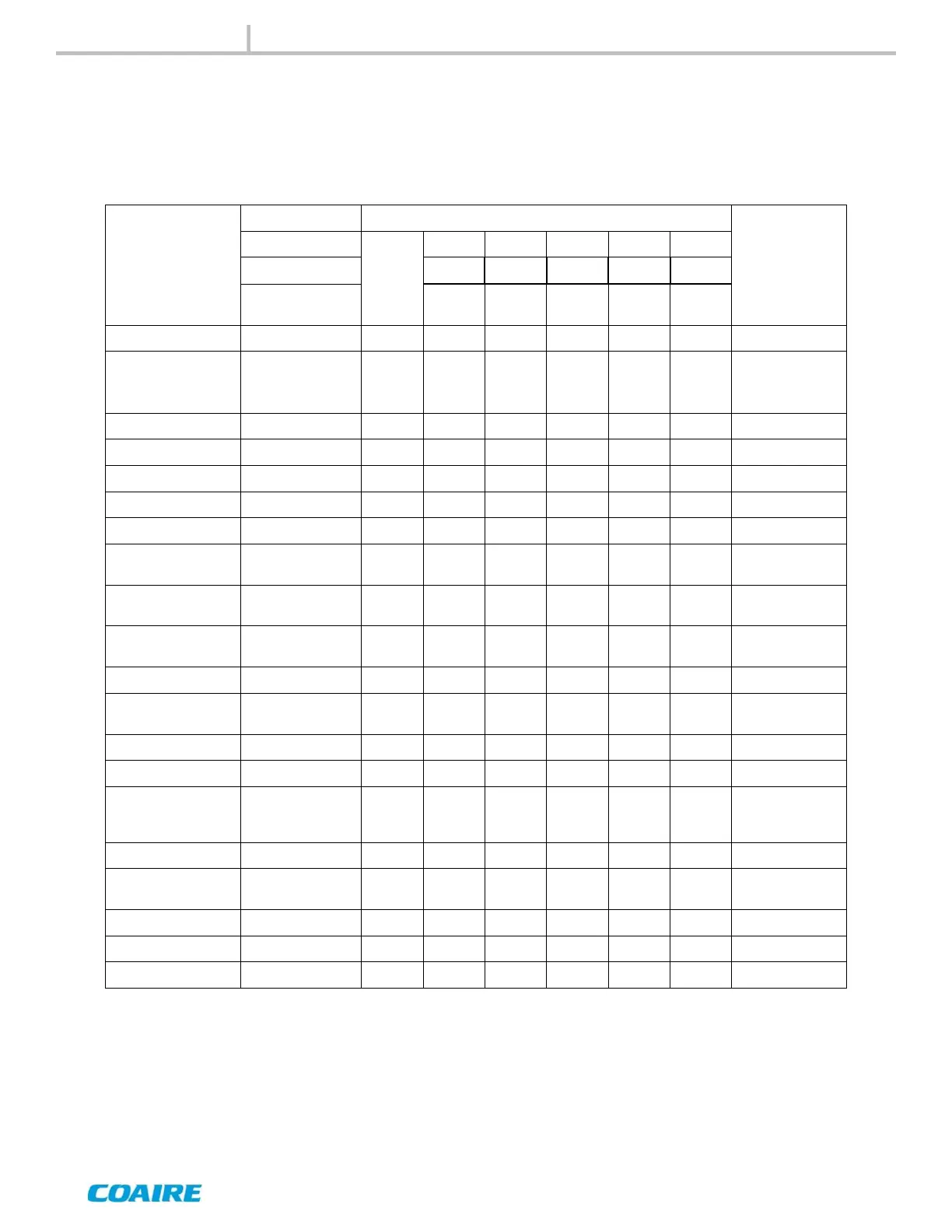

MAINTENANCE

NOTE

Maintenance schedule is instructed as above. The intervals are a guide based on normal operating

conditions. If operated in a severe environment, necessary maintenance service should be performed

on a more frequent basis. User should carry out the maintenance work, based on either the running

hours or the calendar time whichever comes first.

○ : Check, repair : Replace

Section

Action Taken Times Interval

Remarks

Criteria A

Every

day

2 month 1 year 2 years 3 years 6 years

Criteria B 1 month 6 month 1 years 2 years 3 years

Criteria C

0.5

month

3 month 6 month 1 years 2 years

Water Drain Drain out ○

Suction Filter Clean, Replace

○

(500hr)

exchange

in case

of pollution

Air end fan Clean ○ ○

Air end Bearing Clean ○

Air end grease Re-grease ○ ○ ○

Tip seal Replace ○

Dust seal Replace ○

Belt Check, Replace

○

(first)

○

Looseness

makes noise

Temp sensor Check operation ○

Replace case

of abnormal

Pressure Sensor Check operation ○

Replace case

of abnormal

Safety V/V Check operation ○

Check V/V

Check,

Replace

○

Ventilation fan Check ○ ○

Motor pulley Check groove ○

Motor

Check

insulation,

bearing

○

Suction hose Replace ○

After cooler Clean ○

Clean case of

abnormal

Control panel Check monitor ○

Piping Check leak ○

Air end Overhaul ○

8-2 Scheduled Maintenance – High pressure 140 psi (Model : CSOF-M3,5PH/ CSOF-S8,10PH)

Maintenance should be followed below criteria A,B,C

■ Criteria A: Under 2,500 working hours (annually)

■ Criteria B: Between 2,500 ~ 5,000 working hours (annually)

■ Criteria C: Over 5,000 working hours (annually)

Loading...

Loading...