ARJ21-SVV19-13120-00

RampServicingOperation

Instruction

WasteSystem-Drainotherliquid

1.CommonInformation

A.Thisprocedureprovidesthedrainwaterandushthewastetank.

B.Thedrainagepipecanbeproperlyextendedtoavoidcollisionbetweenthedrainwatertruckandthe

engine.Itisrecommendedthatthepipelengthextendedto7.5m.

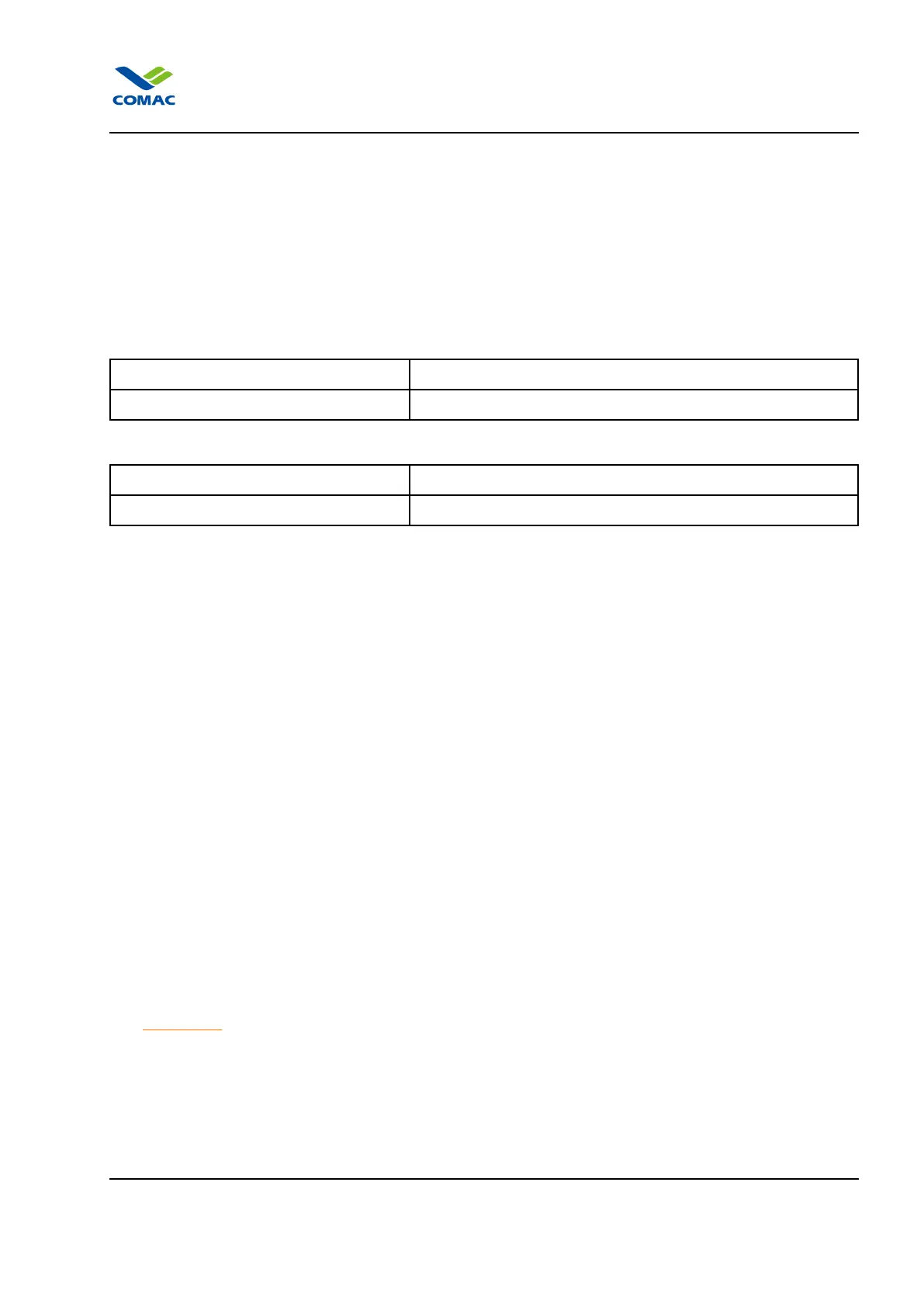

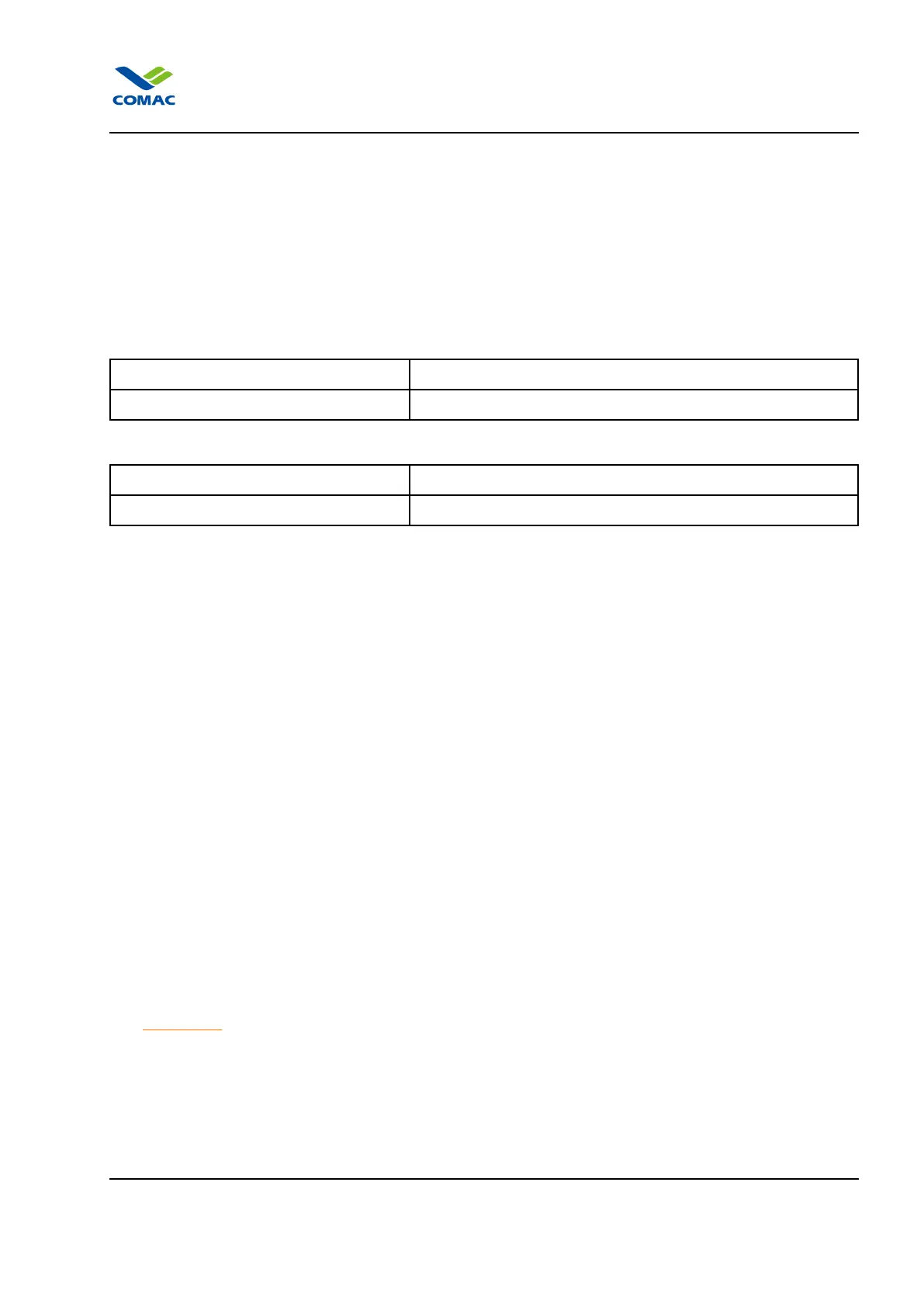

2.PreliminaryRequirements

WorkZones

ZoneLocation

242AftServiceArea-Right

AccessPanels

NumberName

161ALWWasteServiceDoor

3.Procedures

A.Drainthewastetank

(1)Beforedrainwaterfortheaircraft,conrmtheaircraftinspectionwiththesitemaintenanceop-

erator,andstartdraining.

(2)OpenWasteServiceDoor161ALW.

(3)Thedrainwatertruckapproachthedrainpanel.

NOTE:

Keepthesafedistancebetweenthedrainwatertruckandtheengine.

(4)Connectthewastedrainhosefromthelavatoryservicevehicletothewastetankdrainballvalve

assemblyonthewasteservicepanel.

(5)Pushthedrainballvalveleverdownwardstoopenthewastetankdrainballvalve.

(6)Drainthewastetank.

NOTE:

Whilethetankdrains,feelthewastedrainhosetomakesurethattheliquidowsinto

thelavatoryservicevehicle.

B.Flushthewastetank

(1)Pushtherinsettinghandleonthewasteservicepanelupwardstoopentherinsetting.

(2)Connectarinsewaterhosefromthelavatoryservicevehicletotherinsettingonthewaste

servicepanel.

CAUTION:WHENFLUSHINGTHEWASTEWATERTANK,ITISNECESSARYTODRAINTHE

WASTEWATERATTHESAMETIME.OTHERWISE,THEWASTEWILLSOLIDIFY

ONTHEINNERWALLOFTHEWASTETANK,RESULTINGINREDUCTIONOFTHE

VOLUMEOFWASTETANKANDTHEFAULTOFULTRASONICLEVELSENSOR.

(3)Makesurethatthewaterpressuremeetstherequirements,andtheratedpressureis50psi

(345kPa).

ARJ21-A-13-12-24-01A-228A-A

Issue001,2023-01-29

Applicableto:ALL

Page1of3

Loading...

Loading...