15. Sensors

15.1. Sensor fail detection (FLS)

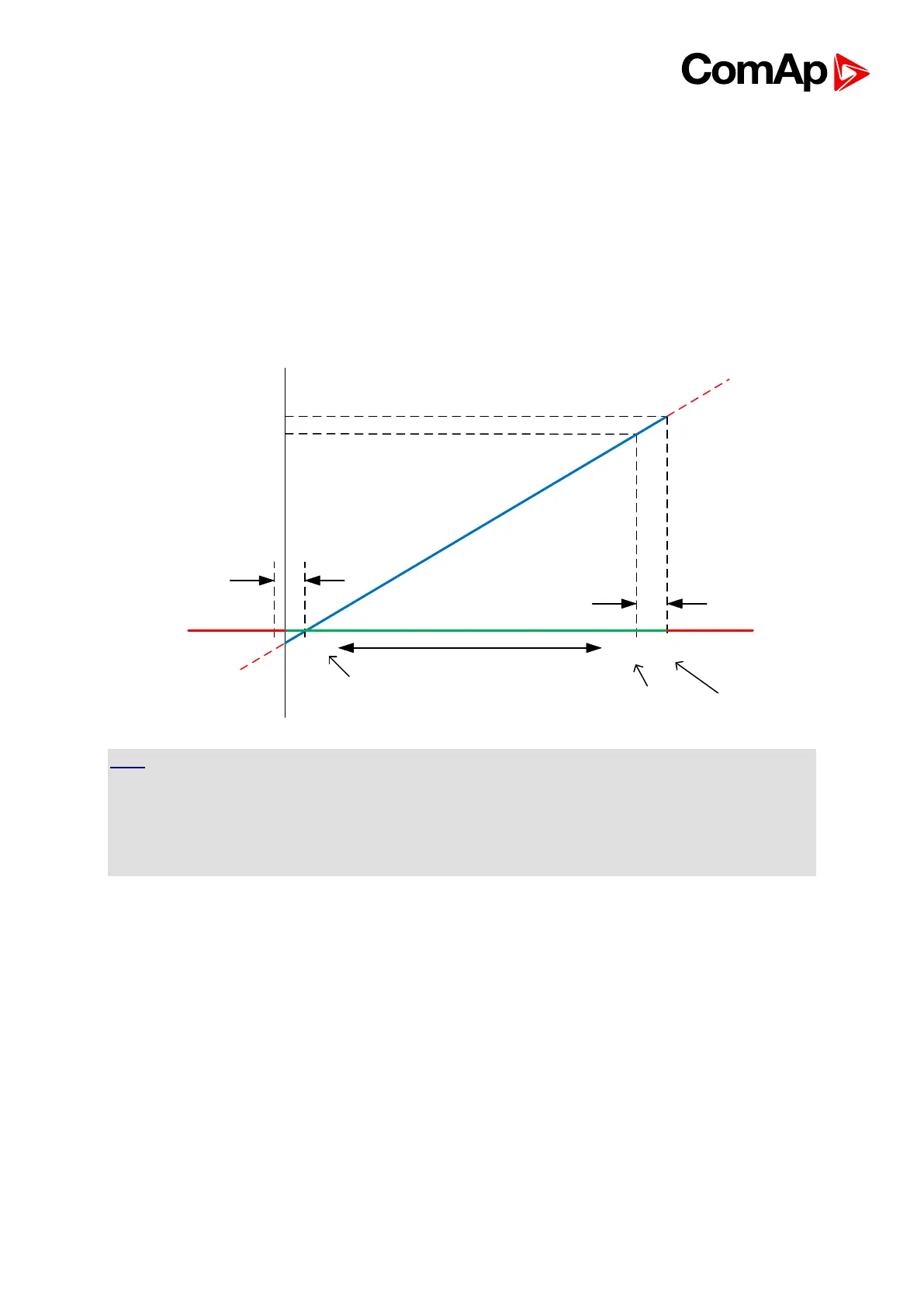

If the measured resistance, voltage or current on an analog input gets out of valid range, the

sensor fail will be detected and a sensor fail message will appear in the alarmlist. The valid

range is defined by the most-left (R

L

) and most-right (R

H

) points of the sensor characteristic

±12.5% from R

H

-R

L

.

12.5% of the

sensor

range (25Ω)

Sensor fail limit would be

-15 Ω what is physically

imposible so sensor fail is

not detected even for 0 ohm

First point of

the curve

100% of the sensor range

Last point of

the curve

Sensor fail

limit

Sensor fail area

10

11,25

Bar

10

210

235

Ω

12.5% of the

sensor

range (25Ω)

-15

HINT

The sensor fail alarm does not influence the gen-set operation. Sensor fail does not activate

Binary output Alarm.

If engine shutdown/stop is required when Fls appears, configure in GenConfig ->

Inputs/Outputs -> Analog inputs -> Protection -> property “Active when” to Under/Over limit +

Fls.

15.2. Default Sensors

There are several predefined sensors which can be used for connection of particular sensor

to analog inputs of the controller. The following list shows predefined standard sensors which

are available in the roller menu.

PT100/°C, PT1000/°C, PT100/°F, PT1000/°F, NI1000/°C, NI1000/°F, 4-20mA active (linear),

0-2400ohm (linear), 0-2.4V (linear), Tristate (for definition please see the chapter about wiring

Analog Inputs)

If you click on Other sensors, following dialog is shown:

Loading...

Loading...